High-purity low-creep-deformation electrofused mullite brick and preparation method thereof

A technology of fused mullite and mullite bricks, which is applied in the field of refractory materials, can solve the problems of high impurity content, unusability, and reduced high-temperature performance, and achieve the effects of ensuring the purity of raw materials, improving bonding strength, and ensuring molding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

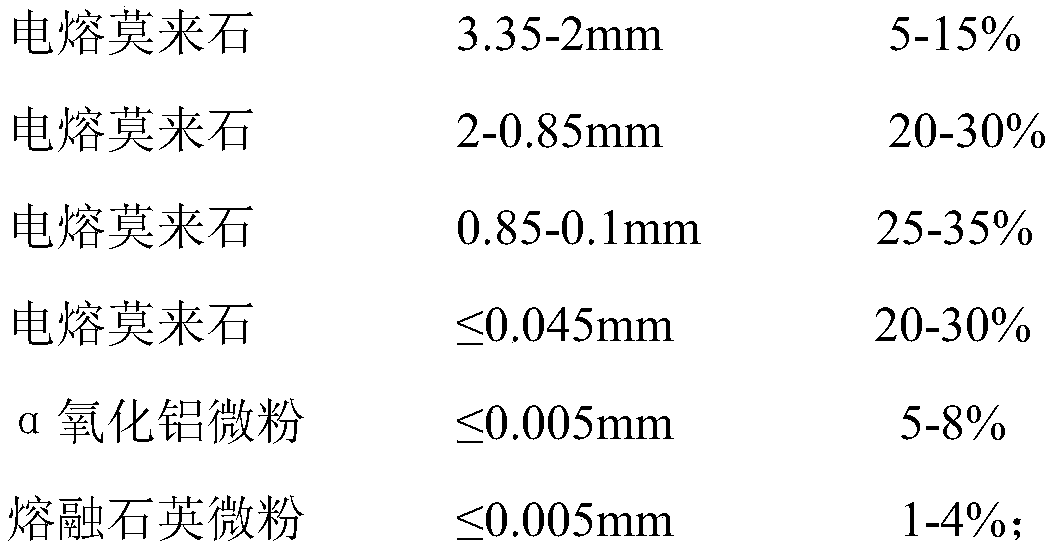

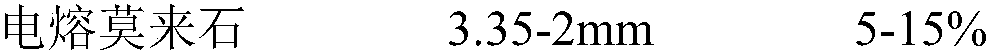

[0037] The high-purity and low-creep fused mullite bricks are composed of the types, particle sizes and weight percentages of raw materials as follows:

[0038] Table 1

[0039]

[0040]

[0041] The preparation method of the described high-purity low-creep fused mullite brick comprises the following steps:

[0042] (1) pre-mixing high-temperature alumina micropowder and fused silica micropowder wet co-grinding to obtain pre-grinding dry powder, and the grinding medium used is alumina grinding ball;

[0043] (2) Semi-dry mixing: use a wheel-rolling mixer, first put the fused mullite particles with a particle size of 0.1mm or more into the wheel-rolling mixer and mix evenly, then add PVA solution and mix evenly, Then add fused mullite fine powder with a particle size of ≤0.045mm, the pre-ground dry powder and cellulose dry powder obtained in step (1) to the cone mixer, and mix for 10-20 minutes to prepare semi-dry mud , put it into the molding press silo to trap the mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com