Special-shaped steel tube forming technology and mold replacement device for semitrailer fence

A special-shaped steel pipe and forming process technology, which is applied in the field of special-shaped steel pipe forming process and mold replacement device for semi-trailer guardrail, can solve the problems of not meeting the development trend of market demand, troublesome mold replacement, complicated production process, etc., and achieve high forming qualified, Good product surface quality and uniform molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

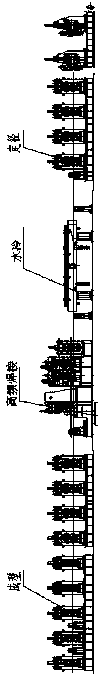

[0041] A special-shaped steel pipe forming process for a semi-trailer guardrail, specifically as follows:

[0042] Uncoiling, install the steel strip coil on the uncoiler, and the uncoiler drives the steel strip coil to rotate and cooperate with the blade to disassemble the steel coil. The center of the steel strip coil is located on the center line of the unit, and a micro-braking device is installed on the uncoiler to prevent the steel strip from being rolled back into an elastic loose coil during an emergency stop.

[0043] Leveling, straight pinch leveling machine middle pressure roller and shovel cooperate with uncoiler to disassemble the steel strip head, and send the steel strip to straight pinch leveler. The shovel cooperates with the straight head pressure roller to straighten the head of the steel strip, and then sends the steel strip to the pinch roller. The pinch roller presses down to clamp the steel strip, and turns the main motor to send the steel strip to the p...

Embodiment 2

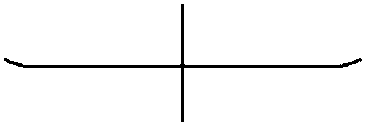

[0063] The difference between this embodiment and Embodiment 1 is that the elastic blocking reset device 5 includes a cross bar perpendicular to the piston rod of the two-way hydraulic cylinder and fixedly connected to the support beam, and a stopper 7 sleeved on the cross bar. Both sides of the block are respectively provided with springs 11 connected to the support beam. The two springs are arranged in a figure-eight shape, and the connection point between the spring and the block is higher than the axis of the cross bar. The lower edges on both sides are provided with circular arc chamfers, the distance from the axis of the cross bar to the front and rear sides of the boss lower part of the block is less than the distance to the upper surface of the support beam, and the front and rear edges of the lower end of the electromagnet are also provided with circular arc chamfers.

[0064] When the electromagnet does not touch the block, the springs on both sides keep it in a balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com