Method for preparing norfloxacin tablets

A technology of norfloxacin tablets and norfloxacin, which is applied in the field of medicine, can solve the problems of poor tablet weight difference, poor fluidity and compressibility, and poor dry stickiness of powder, and achieve dissolution rate and dissolution volume High, increased stability, excellent compressibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

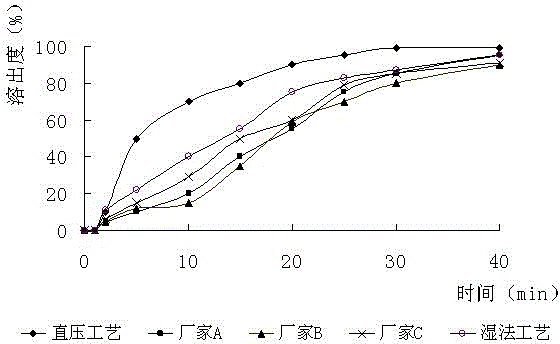

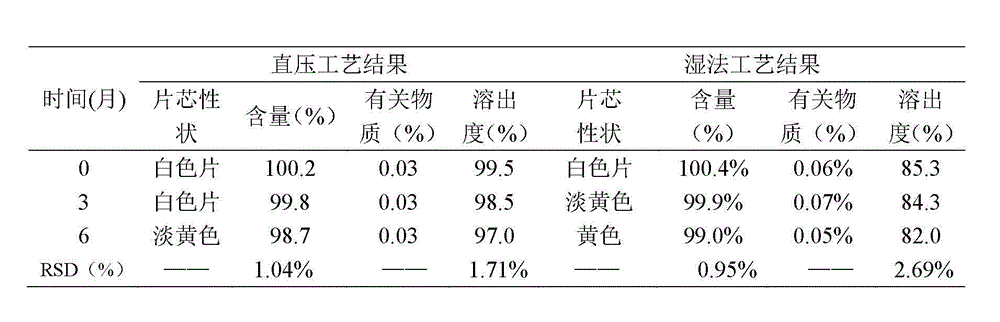

[0031] Get norfloxacin and sieve 40 meshes, hydroxypropyl cellulose, sodium lauryl sulfate, cross-linked polyvinylpyrrolidone sieve 80 meshes, magnesium stearate and silicon dioxide sieve 120 meshes, and norfloxacin Star 100g, hydroxypropyl cellulose 9g, cross-linked polyvinylpyrrolidone 10g, mix evenly, mix 2.5g sodium lauryl sulfate, magnesium stearate 1.5g and silicon dioxide 2.0g, then mix into the aforementioned mixed powder , mixed evenly, and pressed into tablets according to the weight of 0.125g. The tablet is 7kg hard, disintegrates in 4 minutes, and dissolves 99%.

Embodiment 2

[0033] Get norfloxacin and sieve 80 mesh, mannitol, hydroxypropyl methylcellulose, carboxymethyl starch sodium sieve 100 mesh, magnesium stearate and silicon dioxide sieve 120 mesh, and norfloxacin 100g , mannitol 7.5g, hydroxypropyl methylcellulose 20.5g, sodium carboxymethyl starch 18g, mix well, magnesium stearate 2.0g and silicon dioxide 2.0g mix well, then mix into the aforementioned mixed powder, mix well , according to the weight of 0.15g tablets. The tablet is 7kg hard, disintegrates in 5 minutes, and dissolves 98%.

Embodiment 3

[0035] Take norfloxacin and sieve 80 mesh, lactose, pregelatinized starch, maltodextrin, sodium lauryl sulfate, carboxymethyl starch sodium sieve 100 mesh, magnesium stearate and silicon dioxide sieve 100 mesh , mix 100g of norfloxacin, 17g of lactose, 10g of pregelatinized starch, 10g of maltodextrin, 10g of sodium carboxymethyl starch, mix 1g of sodium lauryl sulfate, 1g of magnesium stearate, 1g of silicon dioxide Mix evenly, then mix into the above-mentioned mixed powder, mix evenly, and press into tablets according to the weight of 0.15g. The tablet is 6kg hard, disintegrates in 5.5 minutes, and dissolves 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com