Production method for submerged nozzle of sheet billet

A production method and immersion technology, applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc., can solve the problems of low pass rate, increased manufacturing cost, large size, etc., so as to improve the forming pass rate and save production The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

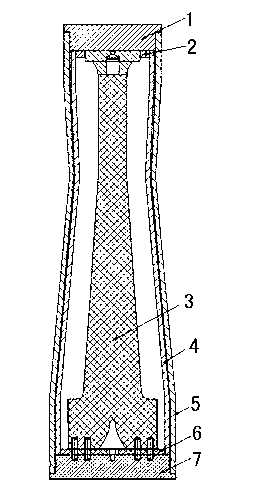

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

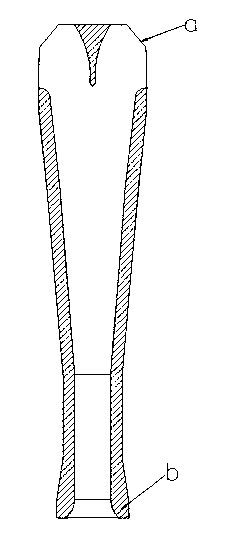

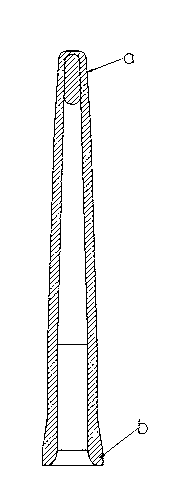

[0019] A thin slab submerged nozzle production method, comprising the following steps: (1), batching: batching raw materials according to predetermined weight percentages; (2), mixing and granulating: mixing the ingredients prepared in the first step, adding Binder, using a granulator to dry the pellets to meet the molding conditions; (3), molding: add the pellets obtained in the second step to the thin slab submerged nozzle combination mold, seal and press the isostatic press to form (4), drying and firing: drying the molded product, and firing in a kiln according to a predetermined temperature curve: (5), processing: machining the product obtained in the fourth step according to the predetermined size requirements to obtain a finished product ; Wherein the thin slab submerged nozzle combination die described in the third step (such as image 3 shown) includes a base 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com