Method for improving magnetic performance of permanent magnetic ferrite

A technology of permanent magnet ferrite and magnetic properties, applied in the direction of magnetic properties of inorganic materials, etc., can solve the problems of inability to obtain magnetic properties, decline of magnetic properties of materials, etc., to improve the molding efficiency and pass rate, excellent magnetic properties, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

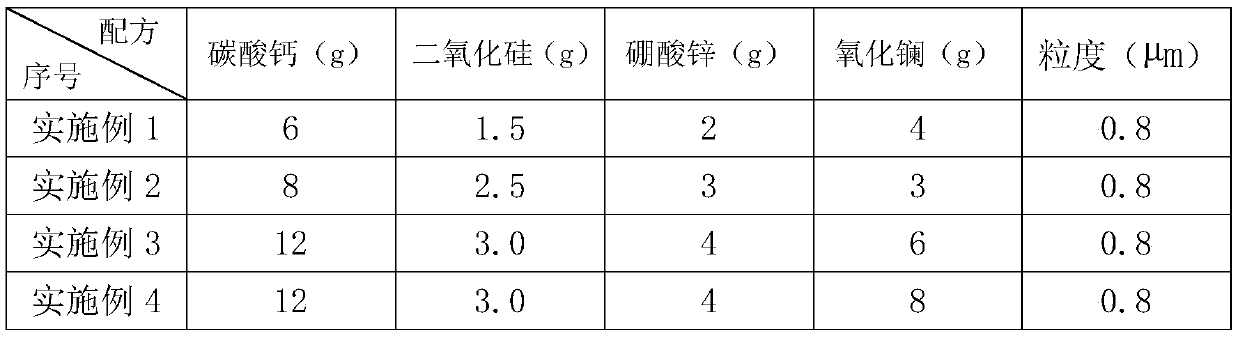

[0029] Each present embodiment comprises the following steps:

[0030] (1) Select permanent magnet ferrite pre-fired material powder, 1000g of each material powder as the main raw material, add permanent magnet ferrite pre-fired material in the ball mill, add additives calcium carbonate, silicon dioxide, zinc borate, Lanthanum oxide, then add water, and ball mill to obtain permanent magnet ferrite slurry;

[0031] (2) Precipitation and filtration of the permanent magnet ferrite slurry obtained in step (1) to obtain the permanent magnet ferrite filter slurry;

[0032] (3) injecting the permanent magnet ferrite filter slurry obtained in step (2) into a mould, and pressurizing and molding under a magnetic field to obtain a permanent magnet ferrite green body;

[0033] (4) Sintering the permanent magnet ferrite green body obtained in step (3) to obtain permanent magnet ferrite.

[0034] Add the main raw materials and formula to the ball mill, add 1500g of water, and ball mill th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com