Method using 0 chromium (Cr) 17 nickel (Ni) 4 copper (Cu) 4 niobium (Nb) thin wall square pipes to machine and manufacture linkage ring guide pipe parts

A linkage ring conduit, processing and manufacturing technology, applied in the field of mechanical processing, can solve the problems of high manufacturing difficulty, poor cryogenic processing performance, low specific strength of titanium alloy, etc., to improve the forming qualification rate, simplify the production process, and achieve significant economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

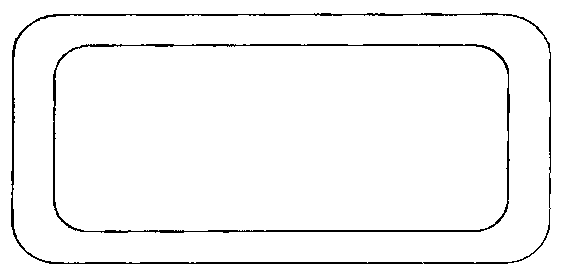

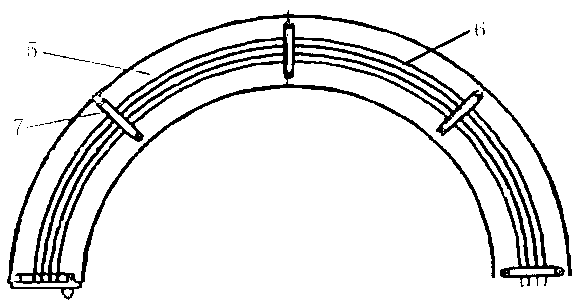

[0022] by figure 1 The 0Cr17Ni4Cu4Nb thin-walled square tube with a wall thickness of 0.57mm is used as the tube material. Remove the burrs on the surface of the tube material, pour rosin into the tube material, and place it in such a figure 2 with image 3 In the roll forming mold shown in the figure, the rocker arm 1 of the roll forming mold is shaken in the circumferential direction to rotate one circle, so that the tube material is roll formed in the roll forming mold, the rosin in the formed tube material is removed, and it is placed Yu Ru Figure 4 Calibrate in the calibration mold shown for 2 hours, cut off the port of the corrected tube material, conduct heat treatment at 1030°C for 30 minutes under vacuum conditions after fluorescent inspection, and then correct in the calibration mold for 2 hours again, after calibration, cut the end, fluorescent Inspect, obtain linkage ring conduit parts such as Figure 5 shown.

Embodiment 2

[0024] by figure 1 The 0Cr17Ni4Cu4Nb thin-walled square pipe with a wall thickness of 0.6 mm shown is the pipe material. Remove the burrs on the surface of the pipe material, pour sand into the pipe material, and place it in such a figure 2 with image 3 In the roll forming mold shown, the rocker arm 1 of the roll forming mold is shaken in the circumferential direction to rotate one circle, so that the pipe material is rolled and formed in the roll forming mold, the sand in the formed pipe material is removed, and it is placed Yu Ru Figure 4 Calibrate in the calibration mold shown for 3 hours, cut off the port of the corrected tube material, conduct heat treatment at 1040°C under vacuum conditions for 20 minutes after fluorescence inspection, and then calibrate in the calibration mold for 3 hours again, after calibration, cut the end, fluorescence Inspect, obtain linkage ring conduit parts such as Figure 5 shown.

Embodiment 3

[0026] by figure 1 The 0Cr17Ni4Cu4Nb thin-walled square pipe with a wall thickness of 0.63mm is the pipe material. Remove the burrs on the surface of the pipe material, pour rosin into the pipe material, and place it in such a figure 2 with image 3 In the roll forming mold shown in the figure, the rocker arm 1 of the roll forming mold is shaken in the circumferential direction to rotate one circle, so that the tube material is roll formed in the roll forming mold, the rosin in the formed tube material is removed, and it is placed Yu Ru Figure 4 Calibrate in the calibration mold shown for 3 hours, cut off the port of the corrected tube material, conduct heat treatment at 1050°C under vacuum conditions for 10 minutes after fluorescence inspection, and then calibrate in the calibration mold for 3 hours again, after calibration, cut the end, fluorescence Inspect, obtain linkage ring conduit parts such as Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com