Full-automatic hard outer shell machine

A cot machine, fully automatic technology, applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of complex structure and low production efficiency of the cot machine, and achieve simple structure, high production efficiency and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

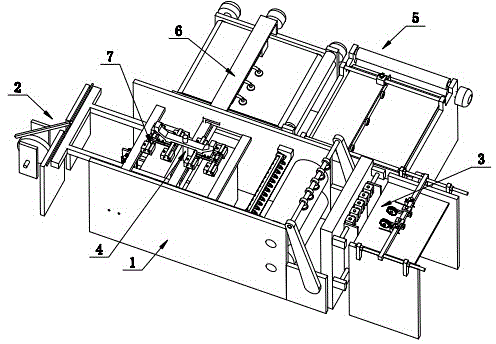

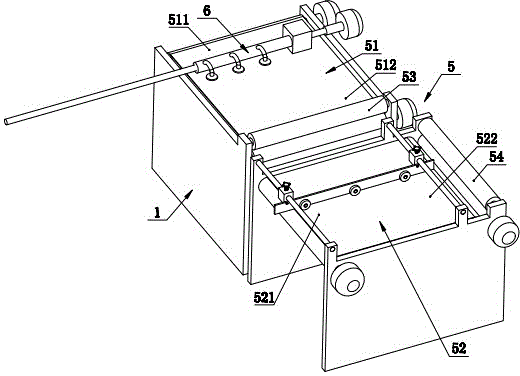

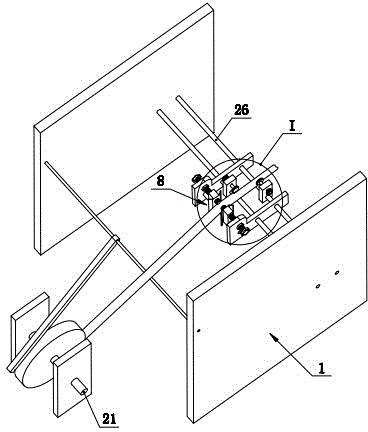

[0023] Such as figure 1 , 2 , 3, 4, 5, 6, and 7 show a kind of full-automatic leather case machine, including body 1, and described body 1 is provided with cardboard conveying device 2, leather seal conveying device 3, leather case hemming Forming device 4 and leather case forming output device 5, the cardboard conveying device 2 and leather seal conveying device 3 are correspondingly arranged at the two ends of the leather case hemming forming device 4, and the leather case forming output device 5 is arranged at the leather case hemming One side of the forming device 4, and the leather shell forming output device 5 is connected with the leather shell hemming forming device 4 through a transfer suction cup 6, wherein the leather shell hemming forming device 4 includes a rotating main shaft 41 and a rotating arm 42 , and a power source 43 for driving the rotating main shaft 41 up and down and rotating, the rotating main shaft 41 is installed on the body 1, the lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com