Polyurethane sieve basket and forming method thereof

A polyurethane and sieve plate technology, applied in centrifuges and other directions, can solve the problems of short service life, low opening rate, and large maintenance amount, and achieve the effect of improving service life, good molding quality, and high molding qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

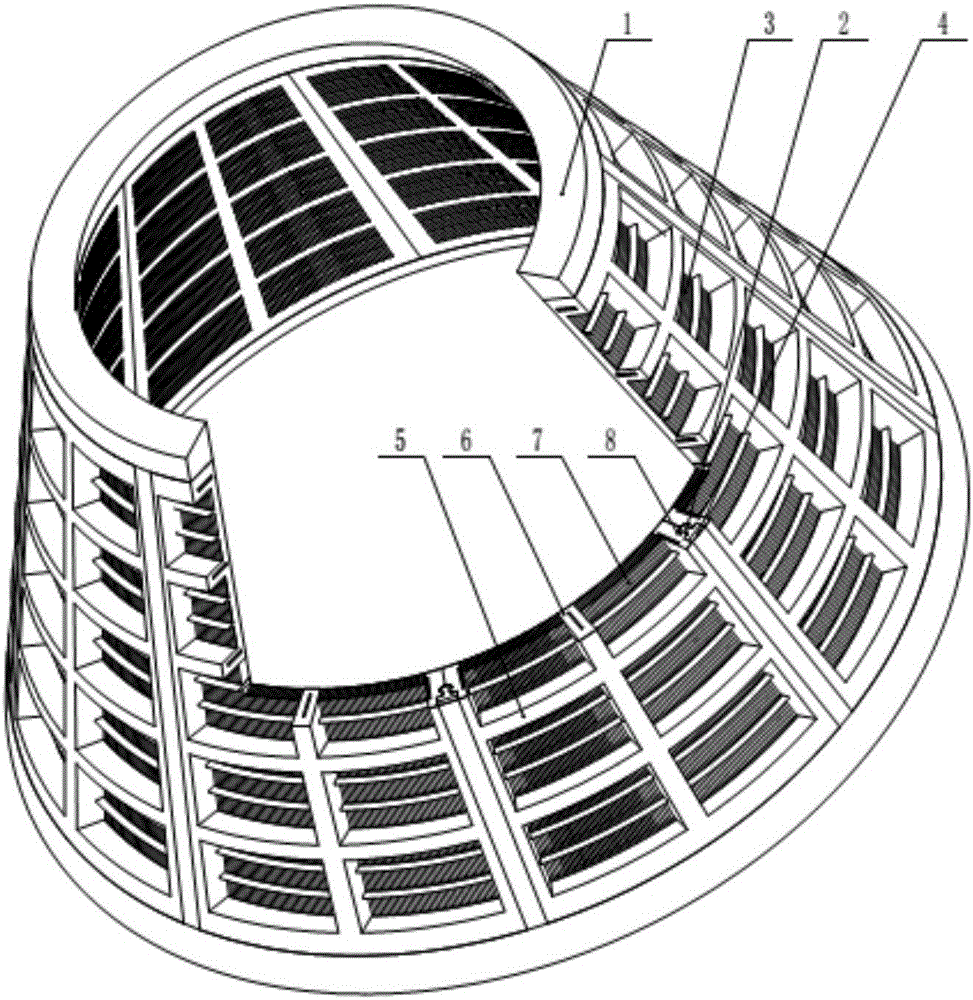

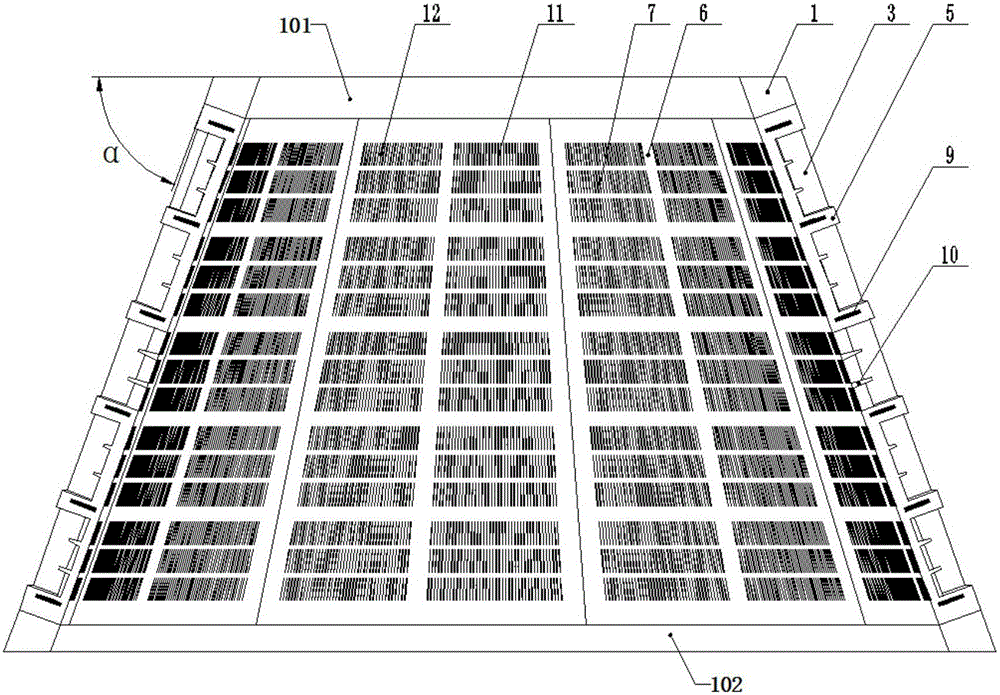

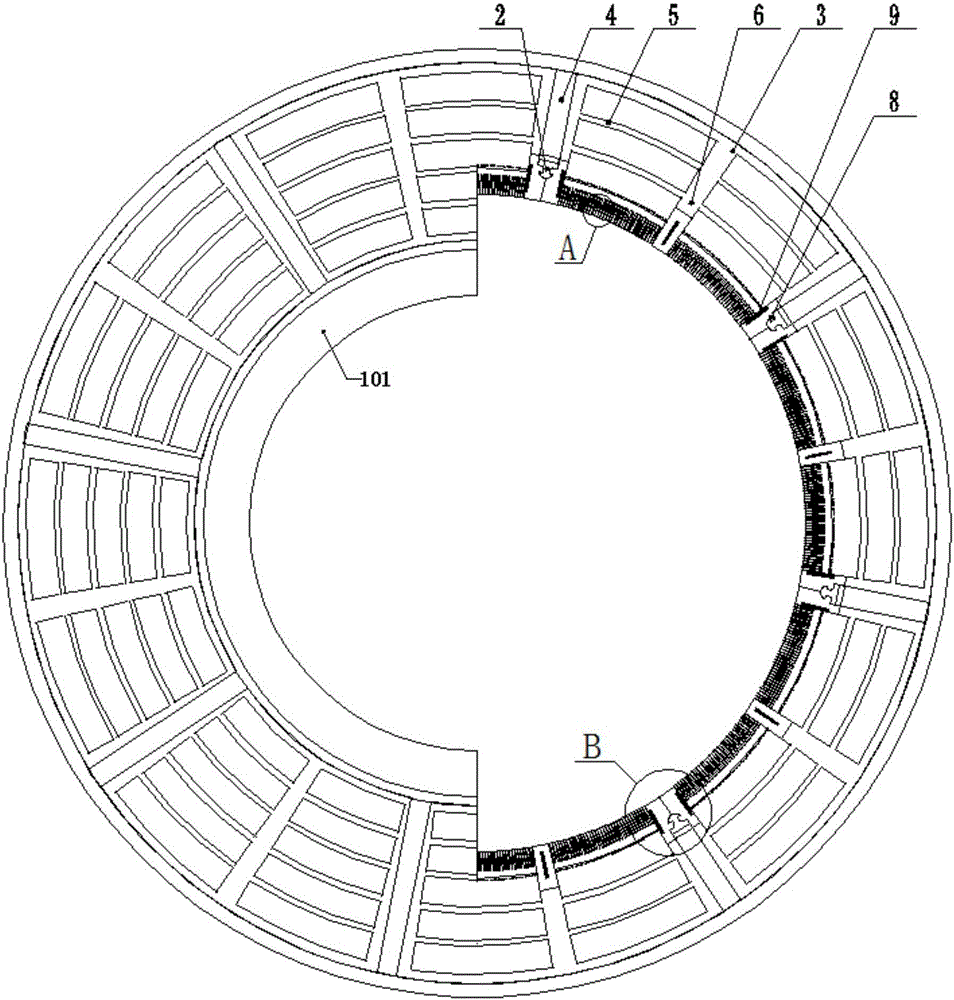

[0041] Figures 1 to 3 , a polyurethane screen basket, comprising a frame body 1 and n sieve plates 3 arranged on the frame body 1, the frame body 1 comprising a bottom frame 101, a top frame 102 and n connecting the bottom frame 101 and the top frame 102 For the spokes 4, a sieve plate 3 is respectively disposed between two adjacent spokes 4, and the two sides of the sieve plate 3 are respectively fixedly connected with the spokes 4; n is a natural number greater than or equal to 2. Here, the sieve plate is made of curved polyurethane sieve plate, and the central angle of the sieve plate is The angle between the screen surface of the screen basket and the bottom plane can be designed between 30° and 90°, and the outer diameter of the bottom frame of the screen basket is between 200 and 2000mm.

[0042] When the angle between the screen surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com