Liquid crystal alignment agent for photo alignment, liquid crystal alignment layer for photo alignment, and liquid crystal display element

A liquid crystal alignment agent and photo-alignment technology, applied in liquid crystal materials, optics, nonlinear optics, etc., can solve problems such as low light transmittance, display defects, and poor display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0461] Hereinafter, the present invention will be described by way of examples. In addition, compounds used in Examples are as follows.

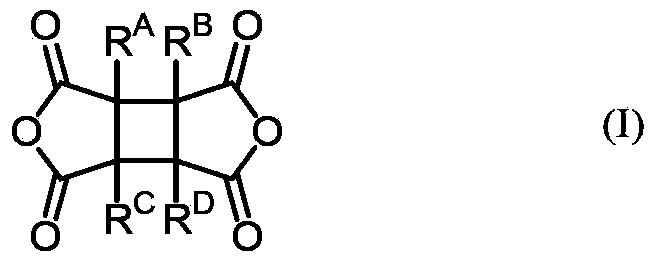

[0462]

[0463] Acid dianhydride (A1): 1,2,3,4-cyclobutanetetracarboxylic dianhydride

[0464] Acid dianhydride (A2): 1,2,3,4-tetramethyl-1,2,3,4-cyclobutanetetracarboxylic dianhydride

[0465] Acid dianhydride (A3): pyromellitic dianhydride

[0466] Acid dianhydride (A4): Butane tetracarboxylic dianhydride

[0467] Acid dianhydride (A5): 1,2,4,5-cyclohexanetetracarboxylic dianhydride

[0468] Acid dianhydride (A6): 3,3′,4,4′-biphenyltetracarboxylic dianhydride

[0469] Acid dianhydride (A7): ethylenediaminetetraacetic dianhydride

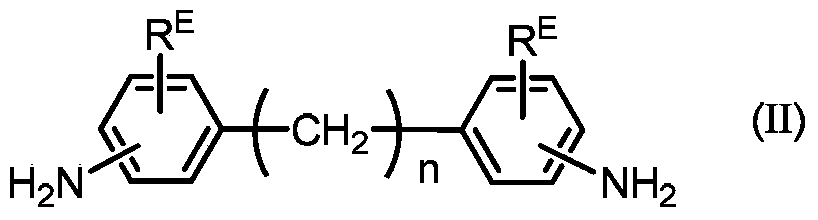

[0470]

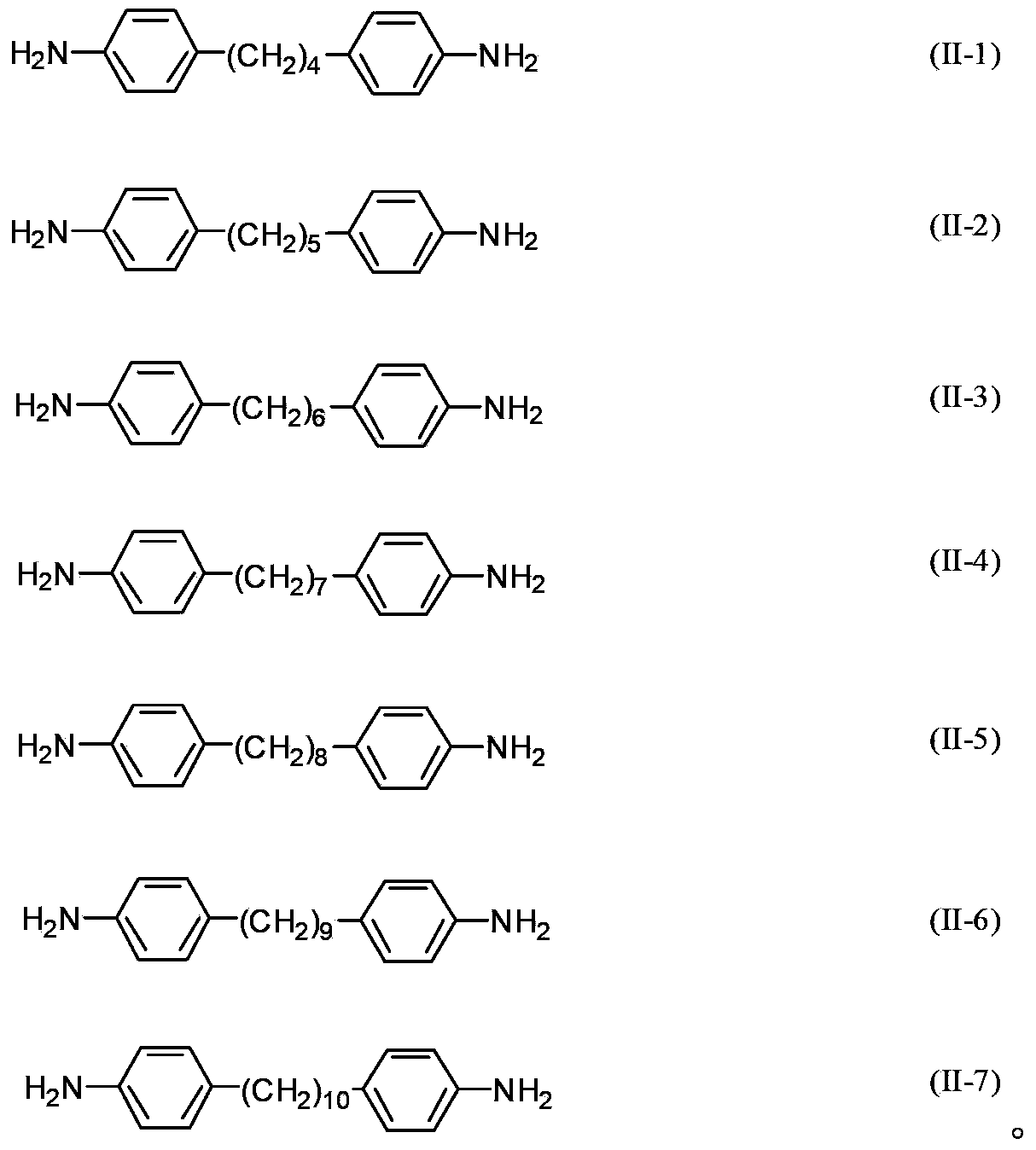

[0471] Diamine (D1): 4,4′-Diaminodiphenylbutane

[0472] Diamine (D2): 4,4′-diaminodiphenylhexane

[0473] Diamine (D3): 4,4′-Diaminodiphenyloctane

[0474] Diamine (D4): 4,4′-diaminodiphenyldecane

[0475] Diamine (D5): 1,4-Phenylenediamine

[0476] Diamine (D6): 4,4′-diaminodiphenylamine ...

Synthetic example 1

[0496] 3.304 g of diamine (D1) and 40.0 g of dehydrated NMP were placed in a 100 mL four-necked flask equipped with a thermometer, a stirrer, a raw material inlet, and a nitrogen inlet, and stirred and dissolved under a dry nitrogen stream. Next, 2.696 g of acid dianhydride (A1) and 40.0 g of dehydrated NMP were added, and stirring was continued at room temperature for 24 hours. BC14.0g was added to this reaction solution, and the polyamic-acid solution whose polymer solid content density|concentration was 6 weight% was obtained. This polyamic acid solution was referred to as PA1. The viscosity of PA1 was 11 mPa·s, and the weight average molecular weight of the polyamic acid contained in PA1 was 22,000.

[0497] The weight average molecular weight of a polyamic acid is calculated|required by the GPC method using the 2695 separation module (seperation module) / 2414 differential refractometer (made by Waters), and it calculated|required by polystyrene conversion. The obtained p...

Embodiment 1

[0507] Add a mixed solvent of NMP / BC=4 / 1 (weight ratio) to the polyamic acid solution (PA1) with a polymer solid content concentration of 6% by weight prepared in Synthesis Example 1, and dilute the polymer solid content concentration to 4% by weight to make a liquid crystal alignment agent. Using the obtained liquid crystal alignment agent, the board|substrate for transmittance evaluation was produced as follows.

[0508]

[0509]The liquid crystal alignment agent was coated in the glass substrate by a spinner. In addition, including the following examples and comparative examples, the rotational speed was adjusted according to the viscosity of the liquid crystal alignment agent, and the alignment film was made to have the following film thickness. After forming the coating film and heating and drying at 80°C for 100 seconds, use the photo-alignment light source device APL-L01212S1-ASN01 manufactured by Ushio Electric Co., Ltd. to align the substrate from the vertical dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com