Liquid crystal aligning agent, liquid crystal alignment film, phase difference film, method for forming phase difference film, liquid crystal display device, and polymer

A technology of liquid crystal alignment agent and phase difference film, which is applied in the direction of liquid crystal materials, polarizing elements, chemical instruments and methods, etc., can solve problems such as liquid crystal layer peeling, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0179]

[0180] The liquid crystal alignment agent is prepared as a solution-like composition in which each component is preferably dissolved in an organic solvent by mixing component [A] as an essential component and other components if necessary in a predetermined ratio. Furthermore, the above-mentioned solution-form composition can also be prepared by filtering with a filter having a pore diameter of about 1 μm after mixing the components.

[0181] The organic solvent is preferably an organic solvent that does not react with [A] component and other components that may be contained. Examples of organic solvents include alcohol-based solvents, ether-based solvents, ketone-based solvents, amide-based solvents, ester-based solvents, and hydrocarbon-based solvents. These organic solvents can be used individually or in combination of 2 or more types.

[0182] As alcoholic solvents such as

[0183] Monoalcohol solvents include methanol, ethanol, n-propanol, isopropanol, n-buta...

Embodiment

[0242] Hereinafter, although this invention is demonstrated concretely based on an Example, this invention is not limited to these Examples. The measurement method of the physical property value is as follows.

[0243] [Weight average molecular weight (Mw) and number average molecular weight (Mn)]

[0244] Mw and Mn of the polymer can be measured under the following conditions by gel permeation chromatography (GPC).

[0245] String: TSKgelGRCXLII manufactured by Tosoh Corporation

[0246] Solvent: THF

[0247] Temperature: 40°C

[0248] Pressure: 68kgf / cm 2

[0249] Standard material: monodisperse polystyrene

[0250] [epoxy equivalent]

[0251] Measured based on JIS C2105 "hydrochloric acid-methyl ethyl ketone method".

[0252] [ 1 H-NMR analysis]

[0253]1 H-NMR analysis uses a nuclear magnetic resonance device (JNM-ECX400P, manufactured by JEOL Ltd.), the measurement frequency is 400MHz, and the measurement solvent is chloroform-d 3 or DMSO-d 6 under the conditi...

Synthetic example 1

[0257] [Synthesis Example 1] (Synthesis of Cinnamic Acid Derivative (C-1))

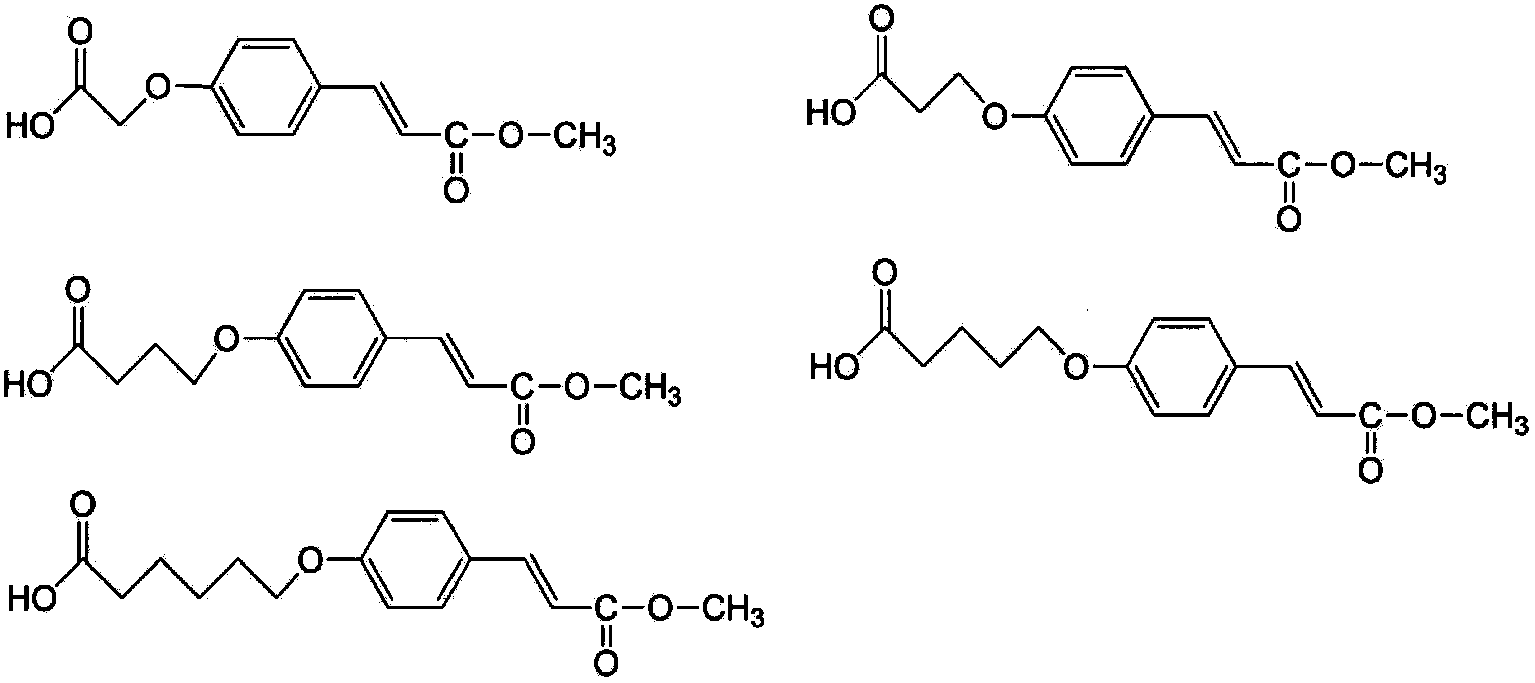

[0258] In a 500mL three-necked flask with a condenser, add 20g of 4-bromodiphenyl ether, 0.18g of palladium acetate, 0.98g of tris(2-tolyl)phosphine, 32.4g of triethylamine and 135mL of dimethylacetamide mix. Next, 7 g of acrylic acid was added and stirred to this mixed solution with a syringe, and heating and stirring were performed at 120° C. for 3 hours. After confirming the completion of the reaction by thin layer chromatography (TLC), the reaction solution was cooled to room temperature. Next, after separating the precipitate by filtration, the filtrate was poured into 300 mL of 1N hydrochloric acid aqueous solution to recover the precipitate. These precipitates were recrystallized with a 1:1 (mass ratio) solution of ethyl acetate and hexane to obtain 8.4 g of a cinnamic acid derivative (C-1) represented by the following formula.

[0259] [chemical 17]

[0260]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com