Liquid crystal alignment agent for forming liquid crystal alignment film for light alignment, liquid crystal alignment film thereof, and liquid crystal display element with the same

A liquid crystal alignment agent and photo-alignment technology, applied in liquid crystal materials, optics, nonlinear optics, etc., can solve the problems of damaged display, poor, low transmittance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

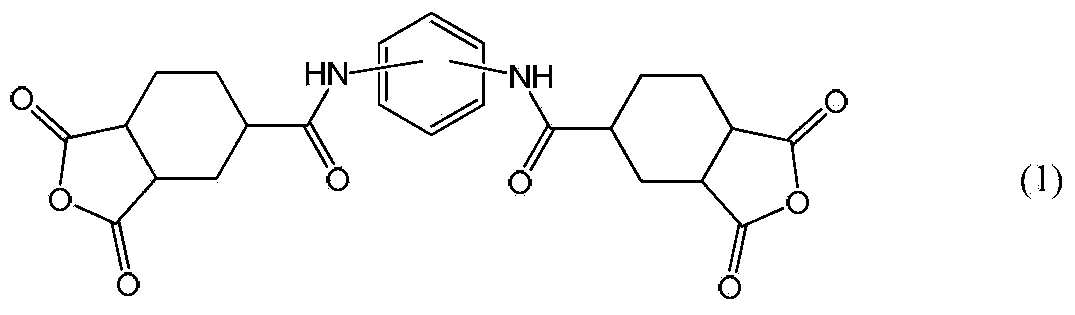

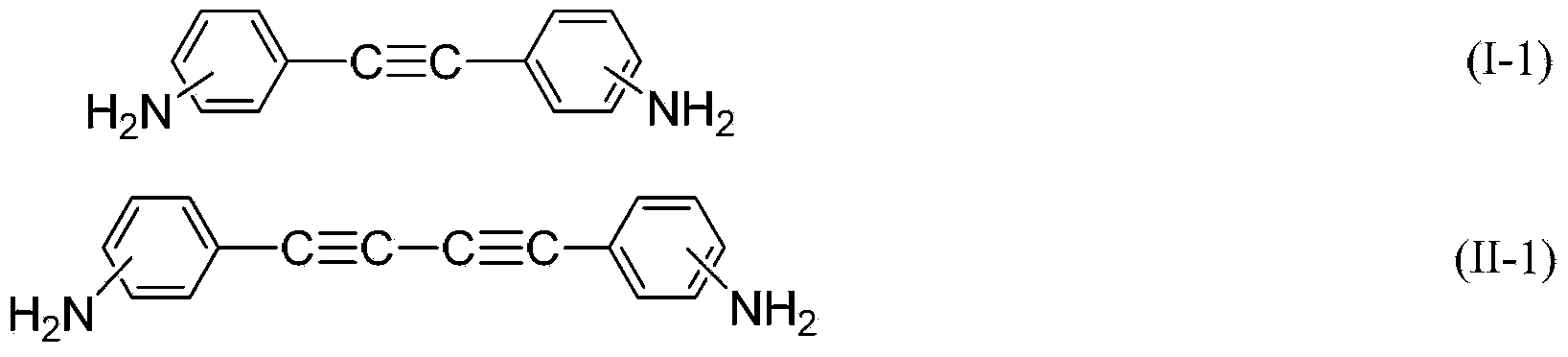

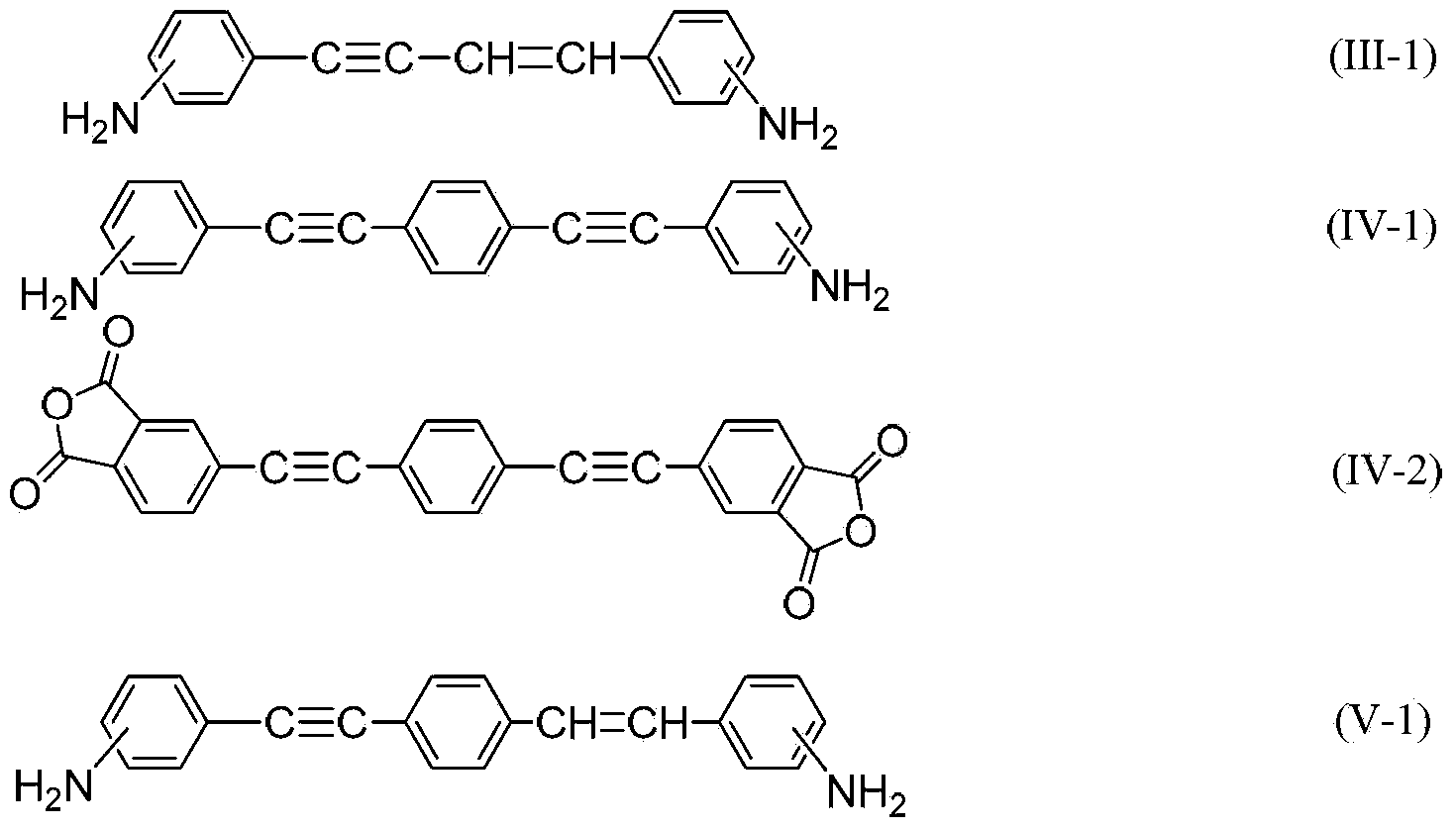

Method used

Image

Examples

Embodiment

[0691] Hereinafter, although an Example demonstrates this invention, this invention is not limited to these Examples. The evaluation method of the liquid crystal display element in an Example is as follows.

[0692]

[0693] The weight average molecular weight of a polyamic acid was calculated|required by the GPC method using 2695 separation module·2414 differential refractometers (made by Waters), and performed polystyrene conversion. The obtained polyamic acid was diluted with a phosphoric acid-dimethylformamide (DMF) mixed solution (phosphoric acid / DMF=0.6 / 100: weight ratio) so that the polyamic acid concentration became about 2 wt%. HSPgel RT MB-M (manufactured by Waters) was used as a column, and the mixed solution was used as a developing solvent, and the measurement was performed under the conditions of a column temperature of 50° C. and a flow rate of 0.40 mL / min. As the standard polystyrene, TSK standard polystyrene manufactured by Tosoh Co., Ltd. was used.

[069...

Synthetic example 1

[0710] 1.543 g of diamine (VII-1-1) and 30.0 g of dehydrated NMP were added to a 50 mL brown four-necked flask equipped with a thermometer, a stirrer, a raw material input port, and a nitrogen gas inlet, and stirred and dissolved under a dry nitrogen stream. Then, 1.140 g of acid dianhydrides (AN-2-1), 0.317 g of (AN-3-2), and 7.0 g of dehydrated NMPs were added, and stirring was continued at room temperature for 24 hours. BC10.0g was added to this reaction solution, and the polyamic-acid solution whose polymer solid content concentration was 6 wt% was obtained. Let this polyamic-acid solution be PA1. The weight average molecular weight of the polyamic acid contained in pA1 was 44,400.

[0711] [Synthesis Example 2~Synthesis Example 10]

[0712] Except for changing tetracarboxylic dianhydride and diamine as shown in Table 1, polyamic acid solutions (PA2) to polyamic acid solutions (PA10) with a polymer solid content concentration of 6 wt% were prepared according to Synthesis...

Synthetic example 11

[0717] 0.596 g of diamine (DI-1-3) and 30 g of dehydrated NMP were added to a 50 mL brown four-neck flask equipped with a thermometer, a stirrer, a raw material input port, and a nitrogen gas inlet, and stirred and dissolved under a dry nitrogen stream. Next, 2.404 g of acid dianhydride (1-a) (manufactured by Nippon Seika Co., Ltd.) and 7.0 g of dehydrated NMP were added, and stirring was continued at room temperature for 24 hours. BC10.0g was added to this reaction solution, and the polyamic-acid solution whose polymer solid content concentration was 6 wt% was obtained. This polyamic acid solution was referred to as pA11. The weight average molecular weight of the polyamic acid contained in PA11 was 57,300.

[0718][Synthesis Example 12~Synthesis Example 29]

[0719] Except for changing tetracarboxylic dianhydride and diamine as shown in Table 2, according to Synthesis Example 11, polyamic acid solutions (PA12) to polyamic acid solutions (pA29) with a polymer solid content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com