Loop for shoelace utilizing asymmetric pulley

a shoelace and asymmetric technology, applied in the direction of lacing hooks, fastenings, footwear, etc., can solve the problems of difficult to tighten or loosen the shoelace of the conventional shoes, difficult to insert the shoelace into the eyelets, the grommets or the rings, and the shoelace is difficult to tighten or loosen. or the shoelace takes a long time to insert, tighten or loosen the shoelace, etc., to prevent the abra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]Reference will now be made in greater detail to preferred embodiments of the invention with reference to the accompanying drawings.

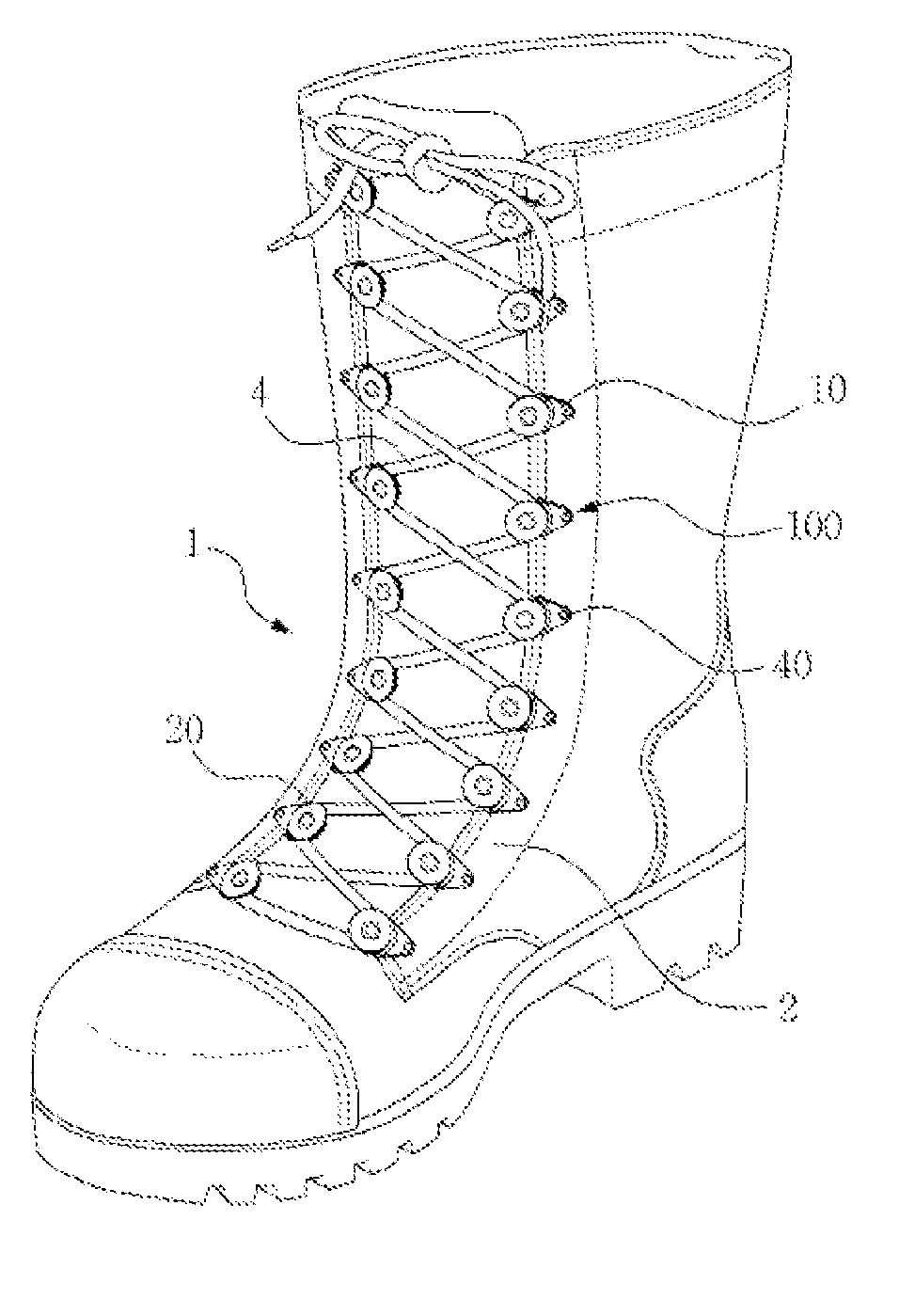

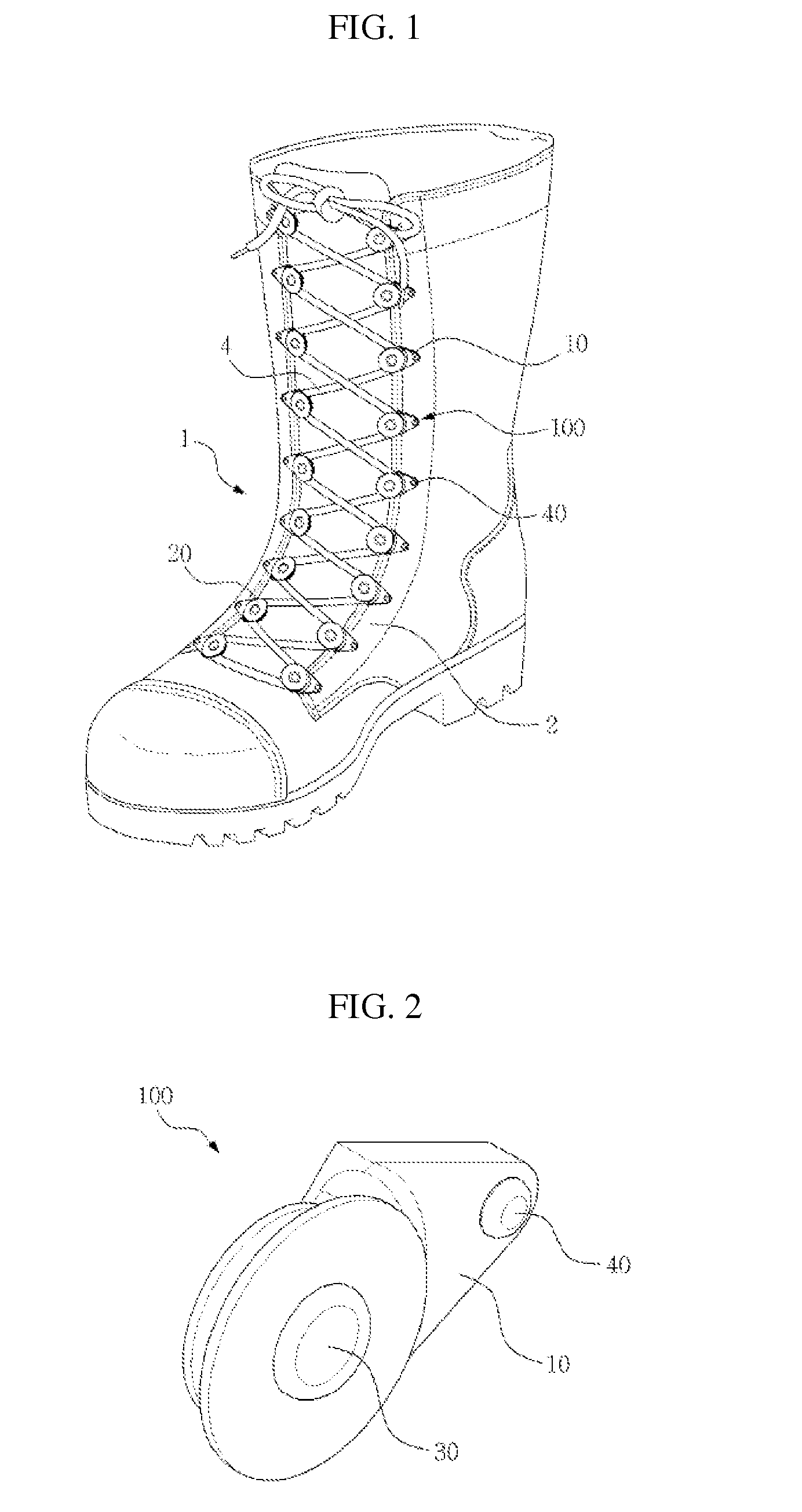

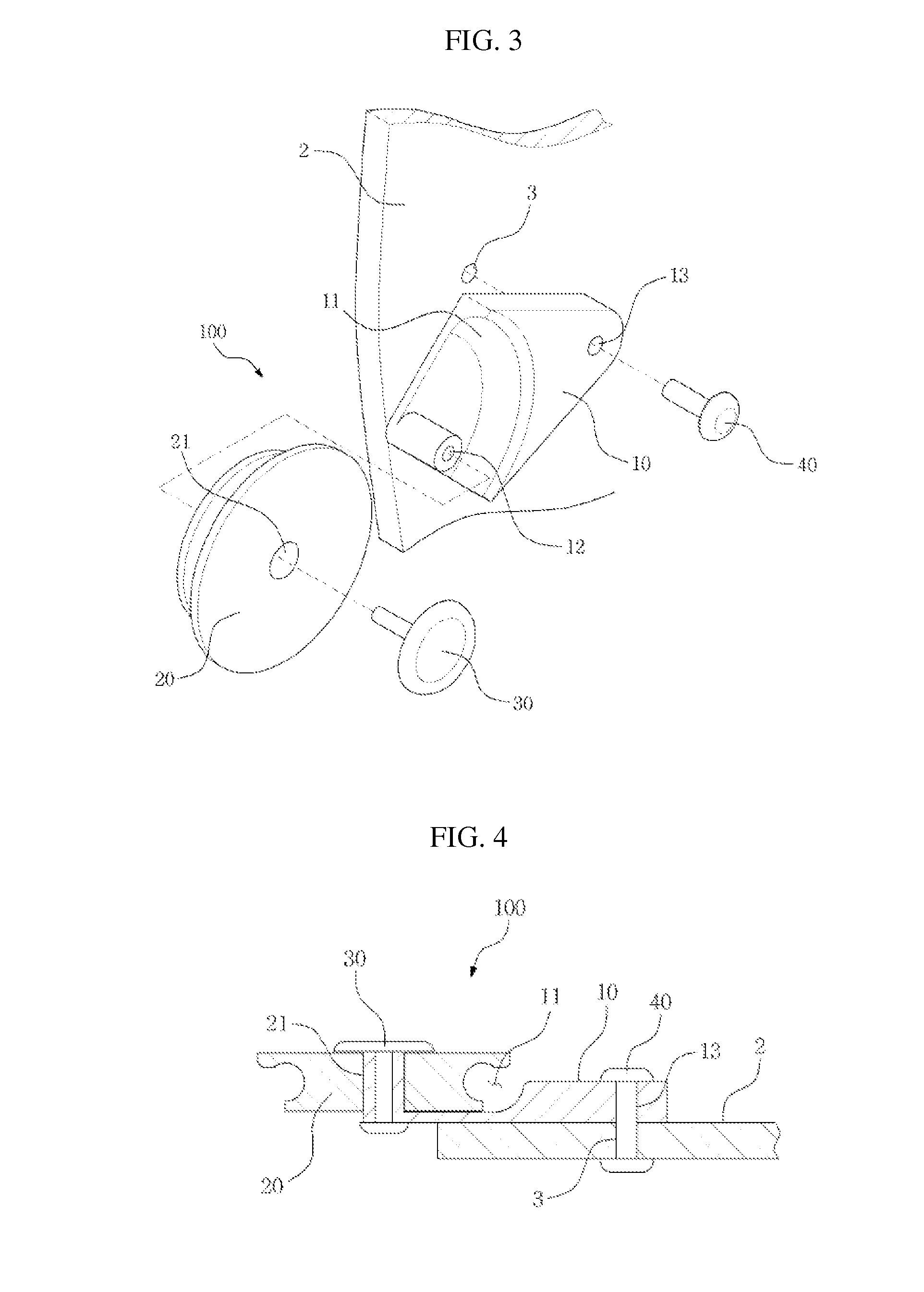

[0029]FIG. 1 is a view illustrating the usage of a shoelace loop according to a first embodiment of the present invention. FIG. 2 is a perspective view illustrating the shoelace loop according to the first embodiment of the present invention. FIG. 3 is an exploded perspective view illustrating the shoelace loop according to the first embodiment of the present invention. FIG. 4 is a sectional view illustrating the shoelace loop according to the first embodiment of the present invention.

[0030]As shown in FIGS. 1 through 4, the first embodiment of the present invention is configured in such a way that a plurality of shoelace loops 100 are mounted to each eyelet tab 2 of a shoe 1 using respective rivets 40 so that a user can easily wear the shoe 1 by lacing a shoelace 4 in the shoe 1 by pushing the shoelace 4 into each of the respective shoelace loops ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com