Weaving and twisting head and weaving and twisting method thereof

A technology of braiding and linear modules, which is applied in the field of textile twisting, can solve the problems of inability to obtain loose silk threads, unfavorable dyeing processing, tight bundles of twisted wires, etc., and achieve the effect of simple structure, simple style and firm style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

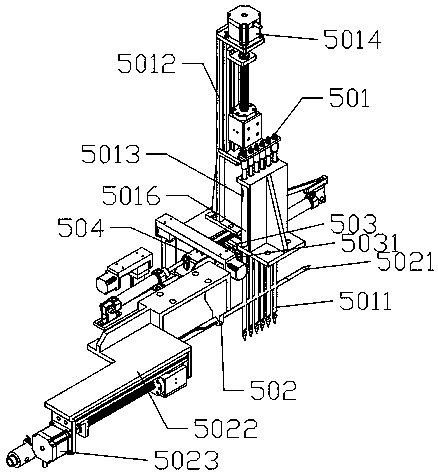

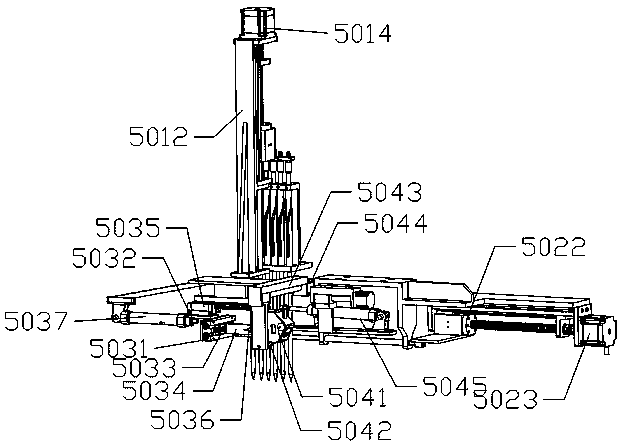

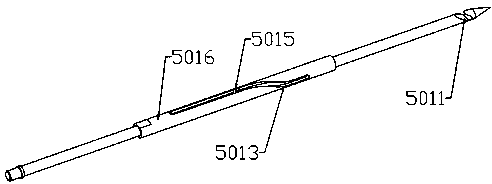

[0037]A braiding head for a braiding machine, including a braided wire feeding mechanism, a needle pricking mechanism 501 moving on the Z axis, a crochet mechanism 502 moving on the Y axis and a wire dividing mechanism 503, and a needle mechanism 503 moving on the X axis Knotting mechanism 504 moving upward; said feeding twisted wire mechanism is located below said needle pricking mechanism 501; said needle pricking mechanism 501 includes pricking needle 5011, said pricking needle 5011 is arranged on the linear module 5012 of the pricking needle mechanism, said pricking needle The linear module 5012 of the mechanism moves in the direction of the Z axis to drive the pricking needle 5011 to move in the direction of the Z axis; the crochet mechanism 502 includes crochet needles 5021 of braided wire, and the crochet needles of braided wire 5021 are arranged on the linear module 5022 of the crochet mechanism. The linear module 5022 of the crochet mechanism moves in the direction of ...

Embodiment 2

[0039] A braiding head for a braiding machine, including a braided wire feeding mechanism, a needle pricking mechanism 501 moving on the Z axis, a crochet mechanism 502 moving on the Y axis and a wire dividing mechanism 503, and a needle mechanism 503 moving on the X axis Knotting mechanism 504 moving upward; said feeding twisted wire mechanism is located below said needle pricking mechanism 501; said needle pricking mechanism 501 includes pricking needle 5011, said pricking needle 5011 is arranged on the linear module 5012 of the pricking needle mechanism, said pricking needle The linear module 5012 of the mechanism moves in the direction of the Z axis to drive the pricking needle 5011 to move in the direction of the Z axis; the crochet mechanism 502 includes crochet needles 5021 of braided wire, and the crochet needles of braided wire 5021 are arranged on the linear module 5022 of the crochet mechanism. The linear module 5022 of the crochet mechanism moves in the direction of...

Embodiment 3

[0047] A braiding head for a braiding machine, including a braided wire feeding mechanism, a needle pricking mechanism 501 moving on the Z axis, a crochet mechanism 502 moving on the Y axis and a wire dividing mechanism 503, and a needle mechanism 503 moving on the X axis Knotting mechanism 504 moving upward; said feeding twisted wire mechanism is located below said needle pricking mechanism 501; said needle pricking mechanism 501 includes pricking needle 5011, said pricking needle 5011 is arranged on the linear module 5012 of the pricking needle mechanism, said pricking needle The linear module 5012 of the mechanism moves in the direction of the Z axis to drive the pricking needle 5011 to move in the direction of the Z axis; the crochet mechanism 502 includes crochet needles 5021 of braided wire, and the crochet needles of braided wire 5021 are arranged on the linear module 5022 of the crochet mechanism. The linear module 5022 of the crochet mechanism moves in the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com