Rapid packer assembly with stable packing quality

A technology with stable quality and high speed, which is applied in the direction of packaging and strapping machine parts, etc. It can solve the problems that the stacks of cartons are not firmly fixed, affect the packing effect of the baler, and the stacks of cartons are not neat enough, etc., to achieve simple structure and low cost , the effect of shooting at the same height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

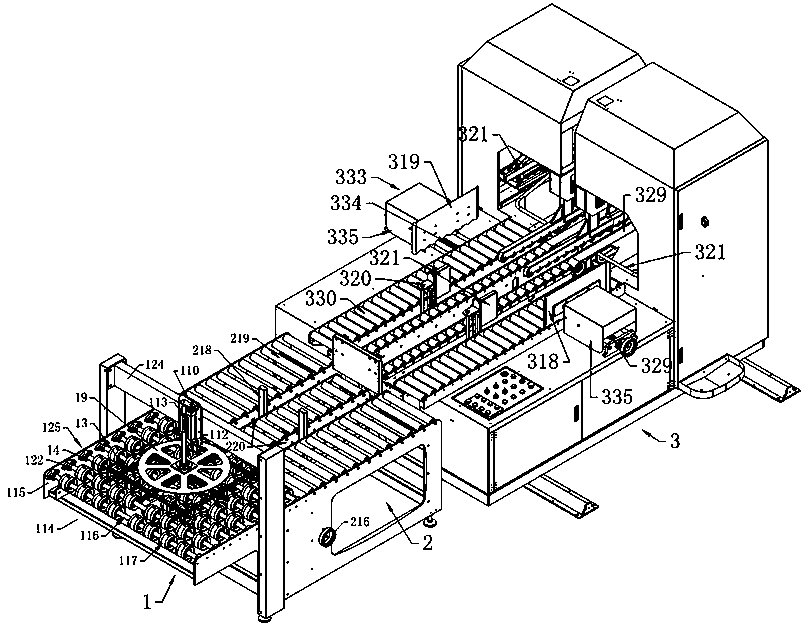

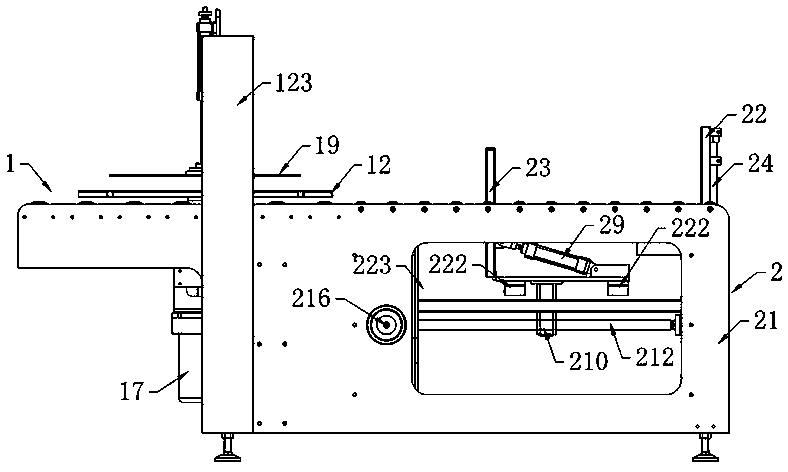

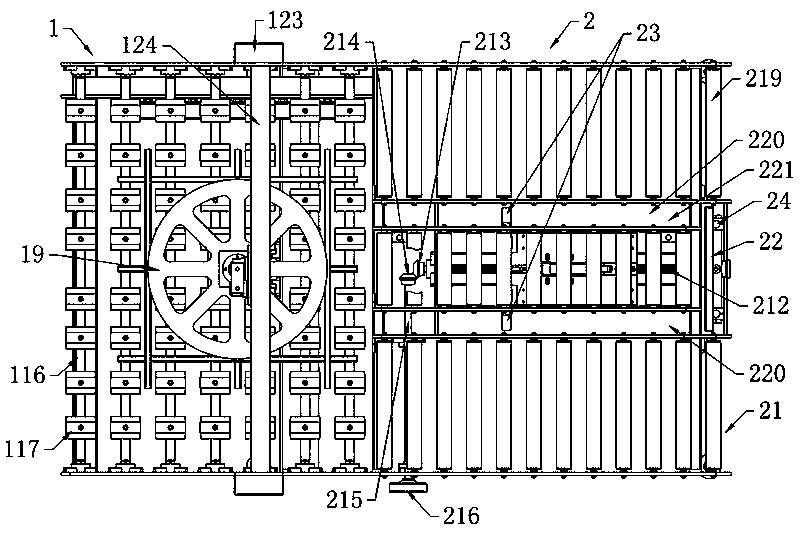

[0040] Such as figure 1 As shown, a fast packing machine assembly with stable packing quality includes an input device and a packing unit 3 arranged in sequence. The input device includes a steering conveying unit 1 and a forward and backward clapping conveying unit 2 arranged sequentially.

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Together, the deflecting conveyor unit 1 comprises a conveying unit 114 and a deflecting unit 11 . The conveying unit 114 includes a bracket 115 and a plurality of parallel second rotating shafts 116 rotatably mounted on the upper end of the bracket 115 , and eight rollers 117 are fixed on each second rotating shaft 116 at intervals. Both ends of the second rotating shaft 116 are equipped with seated bearings 122 , and the seated bearings 122 are fixedly installed on the bracket 115 . The bracket 115 is also provided with a plurality of driving rollers 119 which are rotatably arranged, and a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com