Ecological decorative paper and production method thereof

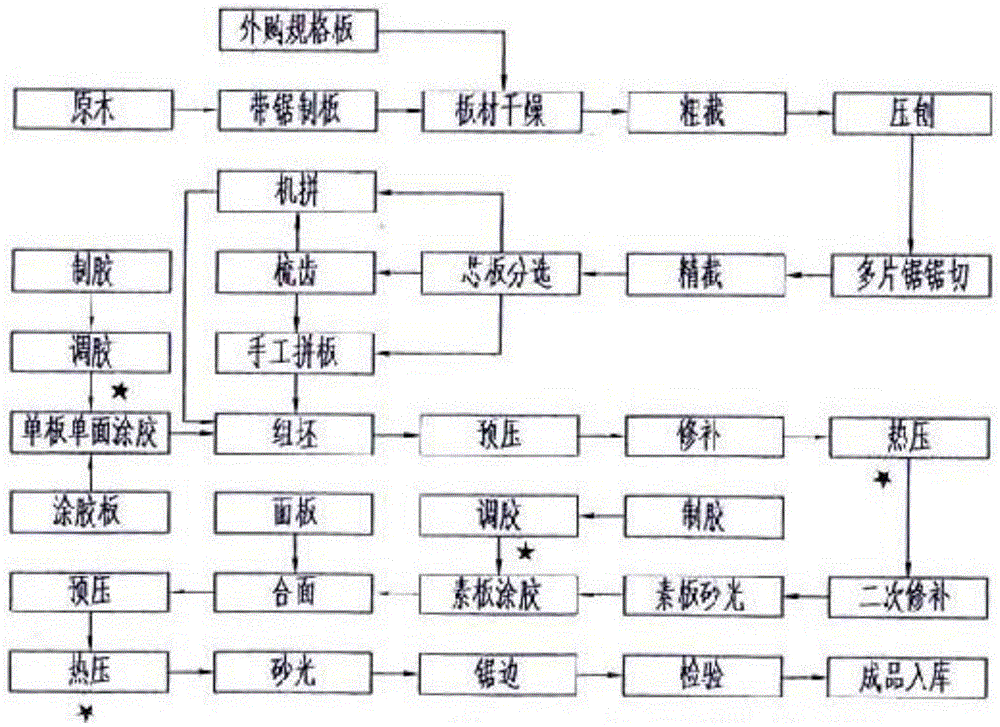

A production method and technology for decorative paper, applied in special paper, paper, papermaking and other directions, can solve the problems of inability to combine veneer and decorative layer by hot pressing, cumbersome processing procedures, heavy panel weight, etc., saving production time and wood. Dosage, the effect of streamlining production processes and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] After preparing materials, calculate by weight: add 20% softwood pulp fiber, 20% hardwood pulp fiber, 10% polyester fiber (1.67D, 6mm), and control the online concentration at 0.38%-0.42%, quantitative 180g / m 2 .

[0053] Glue inside the machine 180g / m 2 . Coating liquid formula: 25 parts of acrylic latex (SJ-2), 25 parts of acrylic latex (R959), and the index of paper is as follows:

[0054] Quantitative 360g / m 2 , thickness 39S, longitudinal tensile strength 1.4KN / m, transverse tensile strength 0.7KN / m.

[0055]After pressing the board, the bonding force is good, there is no delamination phenomenon, and there is no wood silk grain contrasting to the decorative layer.

Embodiment 2

[0057] After preparing materials, calculate by weight ratio: add 15% softwood pulp fiber (25D30mm), 20% hardwood pulp fiber, 15% polyester fiber (6D, 12mm) online concentration control at 0.38%-0.42%, quantitative 200g / m 2 .

[0058] Glue inside the machine 190g / m 2 . Coating liquid formula: 25 parts of acrylic latex (SJ-2), 25 parts of acrylic latex (R959), and the index of paper is as follows:

[0059] Quantitative 390g / m 2 , thickness 39S, longitudinal tensile strength 1.6KN / m, transverse tensile strength 0.92KN / m.

[0060] After pressing the board, the bonding force is good, there is no delamination phenomenon, and there is no wood silk grain contrasting to the decorative layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com