Straw bundling instrument

A technology of equipment and straw, which is applied in the field of straw binding equipment, can solve the problems of easy loosening of straps, high labor cost, poor knotting effect, etc., and achieve the effect of good reset and convenient knotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

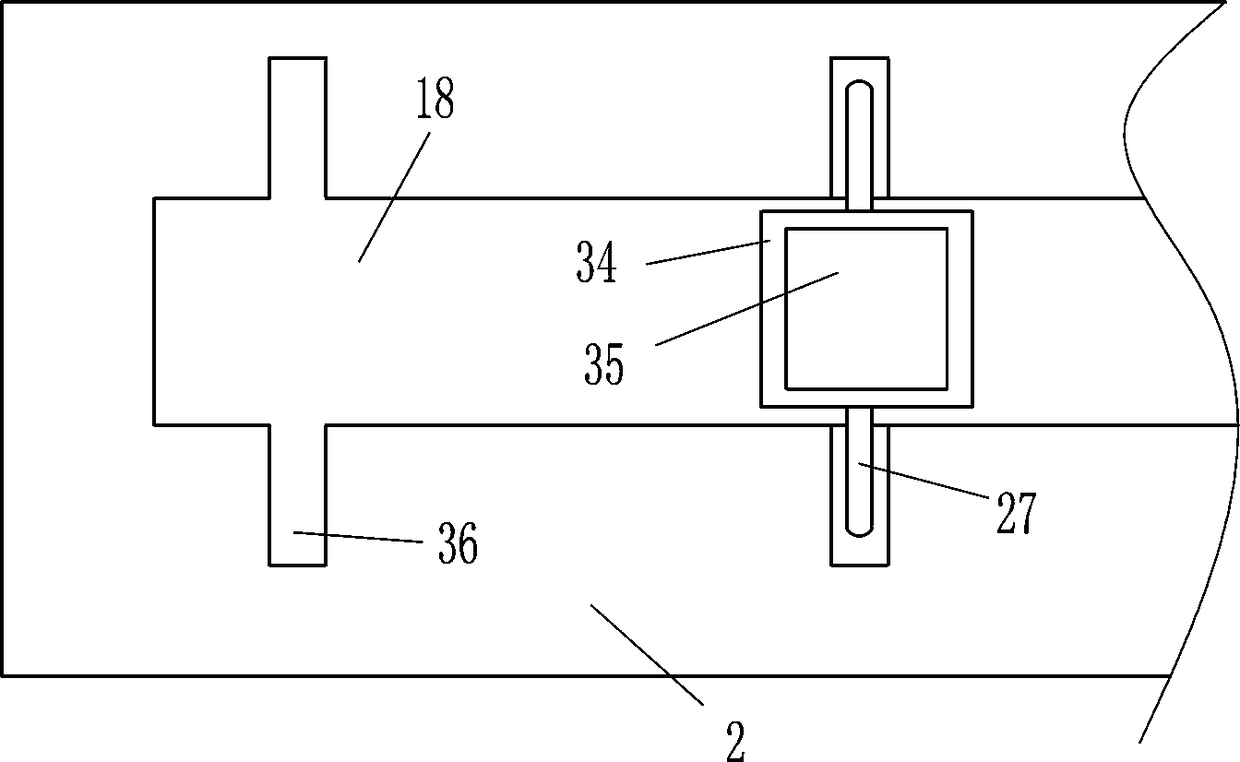

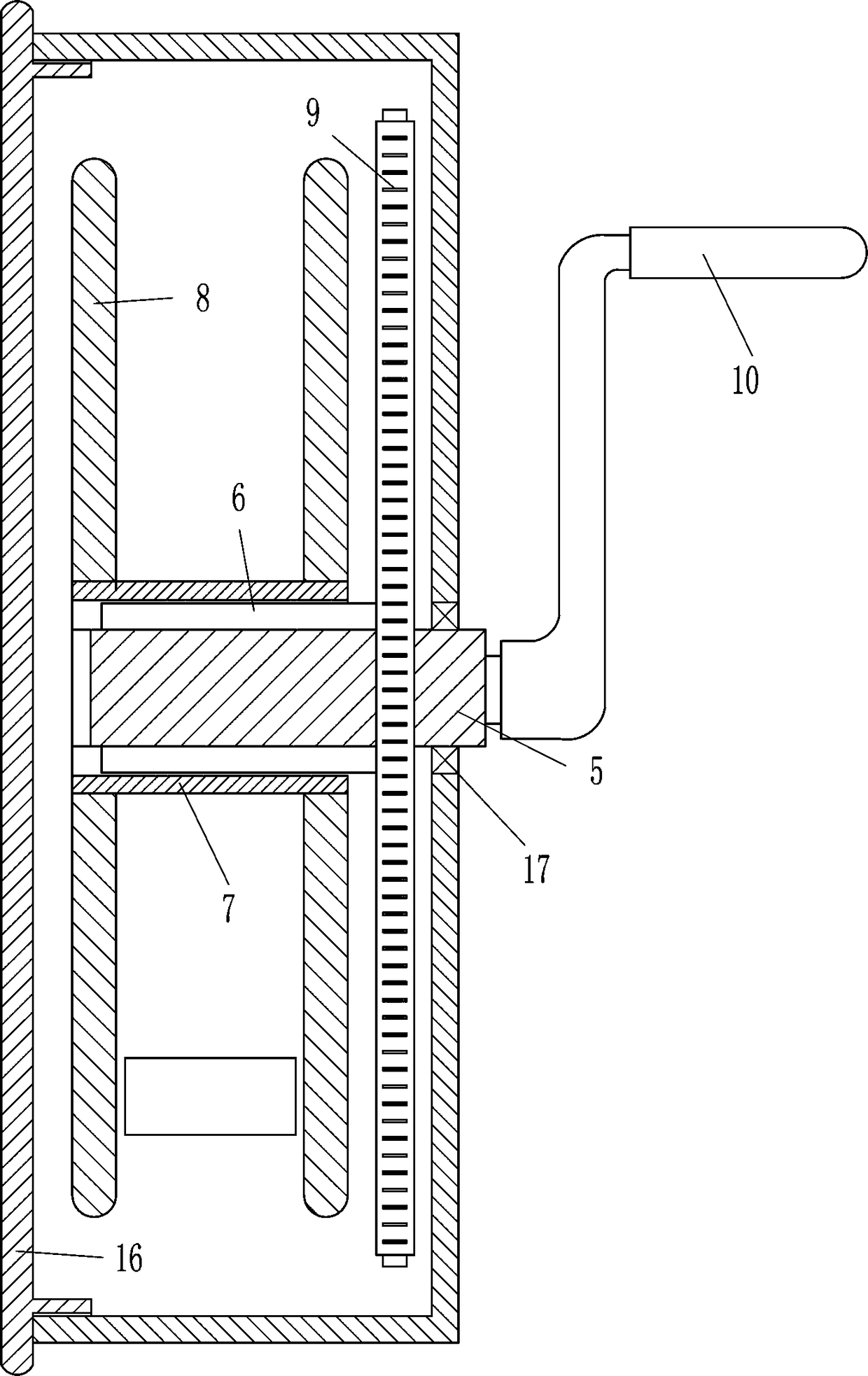

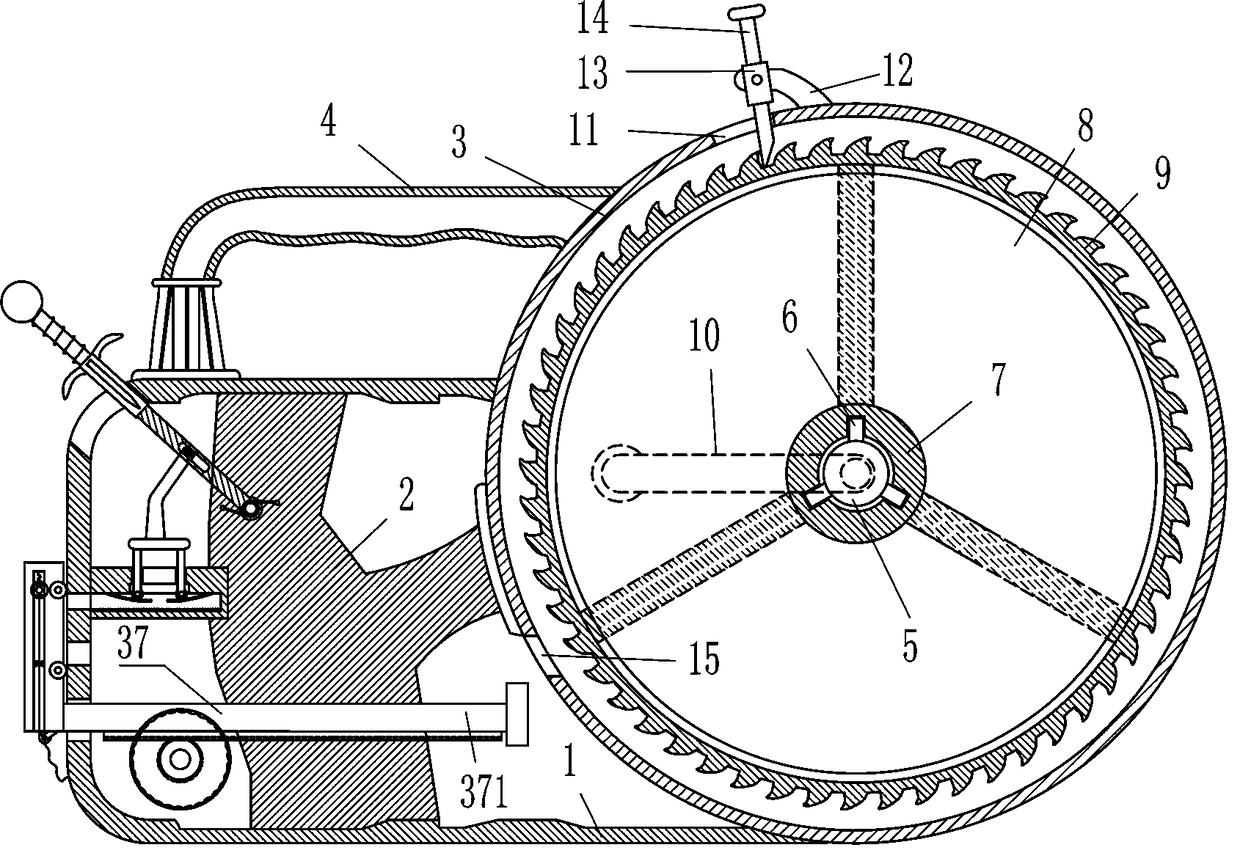

[0020] A straw binding device, such as Figure 1-4As shown, it includes a frame body 1, a support plate 2, a circular frame 3, a handle 4, a rotating shaft 5, a block 6, a sleeve 7, a disc 8, a ratchet 9, a rocker 10, a support rod 12, and a guide sleeve 13 , card rod 14, threaded disc 16, first bearing seat 17, first sleeve 21, toothed strip 22, elastic plate 23, guide rod 25, contact wheel 26, inserting rod 27, horizontal plate 28, rectangular rod 29, Roller 31, connecting rod 32, torsion spring 33, rectangular sleeve 34 and grip bar 35, the right side of frame body 1 is fixed with circular frame 3, and the center of circular frame 3 is embedded with a first bearing Seat 17, the rotating shaft 5 is connected with the inner bearing of the first bearing seat 17, the rocker 10 is fixedly connected with the rear end of the rotating shaft 5, the front part of the rotating shaft 5 is fixedly connected with blocks 6 evenly spaced, and the sleeve 7 is sleeved on the front part of th...

Embodiment 2

[0022] A straw binding device, such as Figure 1-4 As shown, it includes a frame body 1, a support plate 2, a circular frame 3, a handle 4, a rotating shaft 5, a block 6, a sleeve 7, a disc 8, a ratchet 9, a rocker 10, a support rod 12, and a guide sleeve 13 , card rod 14, threaded disc 16, first bearing seat 17, first sleeve 21, toothed strip 22, elastic plate 23, guide rod 25, contact wheel 26, inserting rod 27, horizontal plate 28, rectangular rod 29, Roller 31, connecting rod 32, torsion spring 33, rectangular sleeve 34 and grip bar 35, the right side of frame body 1 is fixed with circular frame 3, and the center of circular frame 3 is embedded with a first bearing Seat 17, the rotating shaft 5 is connected with the inner bearing of the first bearing seat 17, the rocker 10 is fixedly connected with the rear end of the rotating shaft 5, the front part of the rotating shaft 5 is fixedly connected with blocks 6 evenly spaced, and the sleeve 7 is sleeved on the front part of t...

Embodiment 3

[0025] A straw binding device, such as Figure 1-4 As shown, it includes a frame body 1, a support plate 2, a circular frame 3, a handle 4, a rotating shaft 5, a block 6, a sleeve 7, a disc 8, a ratchet 9, a rocker 10, a support rod 12, and a guide sleeve 13 , card rod 14, threaded disc 16, first bearing seat 17, first sleeve 21, toothed strip 22, elastic plate 23, guide rod 25, contact wheel 26, inserting rod 27, horizontal plate 28, rectangular rod 29, Roller 31, connecting rod 32, torsion spring 33, rectangular sleeve 34 and grip bar 35, the right side of frame body 1 is fixed with circular frame 3, and the center of circular frame 3 is embedded with a first bearing Seat 17, the rotating shaft 5 is connected with the inner bearing of the first bearing seat 17, the rocker 10 is fixedly connected with the rear end of the rotating shaft 5, the front part of the rotating shaft 5 is fixedly connected with blocks 6 evenly spaced, and the sleeve 7 is sleeved on the front part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com