Magnetic core-shell Fenton-type catalyst, and preparation method and application of catalyst

A catalyst, core-shell technology, applied in the fields of nanomaterials and environmental science, can solve the problems of inability to maintain high activity, reduce catalyst activity, catalyst poisoning, etc., to reduce the possibility of pollution and poisoning, reduce surface energy, and prevent agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

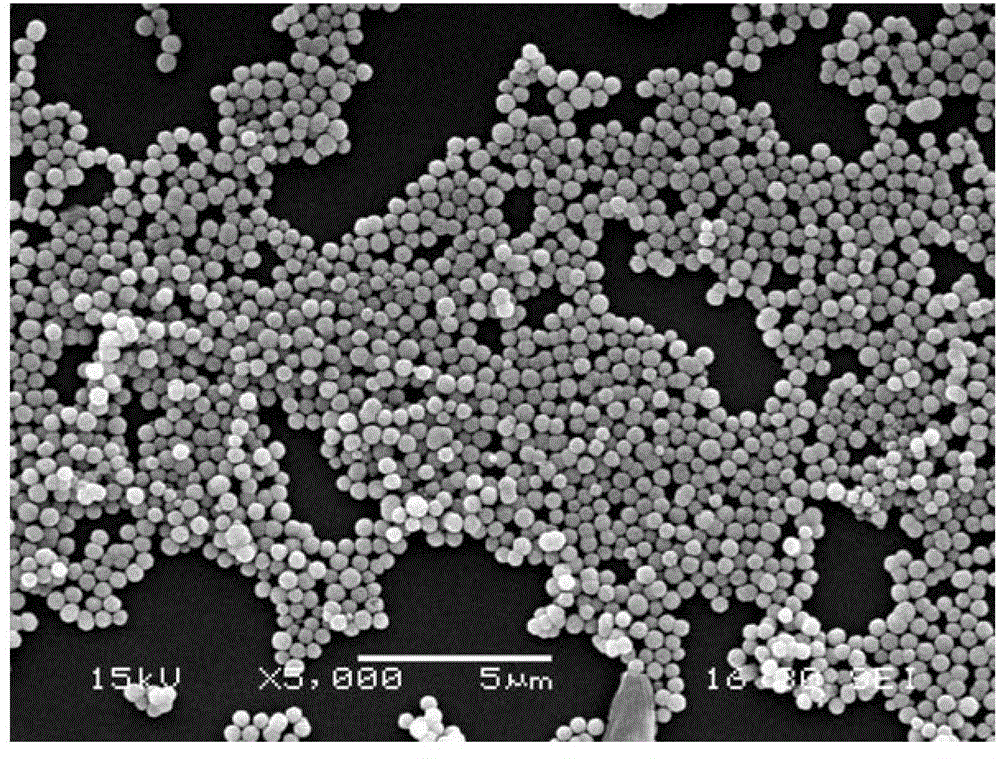

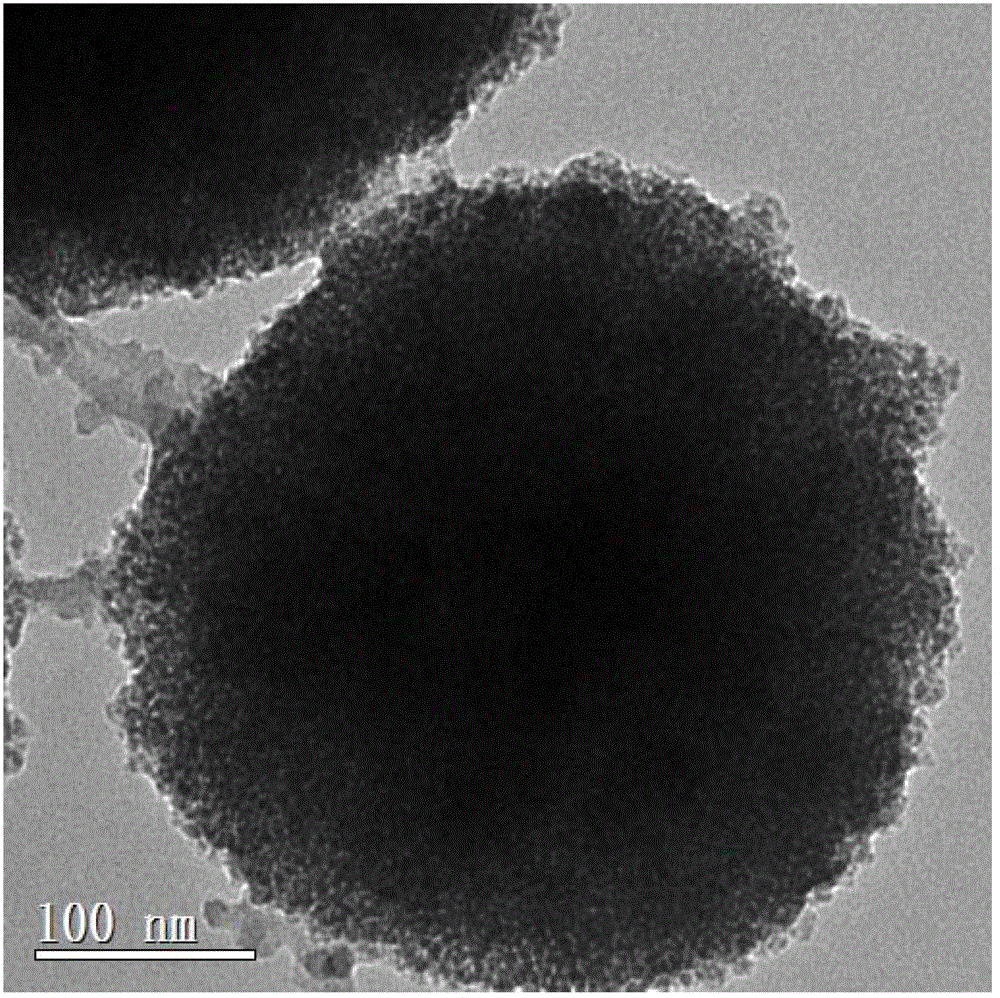

[0028] (1) Fe 3 o 4 Preparation of microspheres: 1.3 g of FeCl 3 , 0.5g of sodium citrate, 2.0g of sodium acetate were added to 40mL of ethylene glycol in turn, after stirring evenly, transferred to a 100mL hydrothermal kettle, after hydrothermal reaction at 200°C for 10h, cooled to room temperature, centrifuged, After the product was washed 3 times with absolute ethanol and ultrapure water, it was dried for later use; the product Fe 3 o 4 The SEM pictures of the microspheres are as figure 1 As shown, the high-resolution TEM photographs are as figure 2 shown;

[0029] (2) Nano SiO 2 Preparation of particles: Prepare a solution of ethyl orthosilicate, absolute ethanol and water at a volume ratio of 1:2:2, raise the temperature to 70°C, stir for 1.5h, then add 2.0mol / L ammonia solution, and continue the reaction for 1h Prepared 30nm nano-SiO 2 particles;

[0030] (3) Fe 3 o 4 / (PE / SiO 2 ) n Preparation of microspheres:

[0031] I. Cationic polyelectrolyte (PDDA) ...

Embodiment 2

[0036] The heterogeneous Fenton method is adopted to process phenol-containing wastewater, using the Erlenmeyer flask as the reactor, the initial concentration of wastewater is 15mg / L, and the Fe prepared in 100mg / L embodiment 1 is added simultaneously. 3 o 4 / (PDDA / 30-SiO 2 ) 3 Composite microspheres and 10mmoL / L of H 2 o 2 , place the reactor in a water bath shaker with a rotation speed of 150 rpm and a temperature of 30 °C.

[0037] According to the direct method in the national standard (GB7491.87), the concentration of phenol was determined. The results showed that Fe 3 o 4 / (PDDA / 30-SiO 2 ) 3 The heterogeneous Fenton method with composite microspheres as a catalyst has a good effect on the treatment of phenol wastewater. After 1 hour of reaction, the removal rate of phenol reaches more than 90%.

Embodiment 3

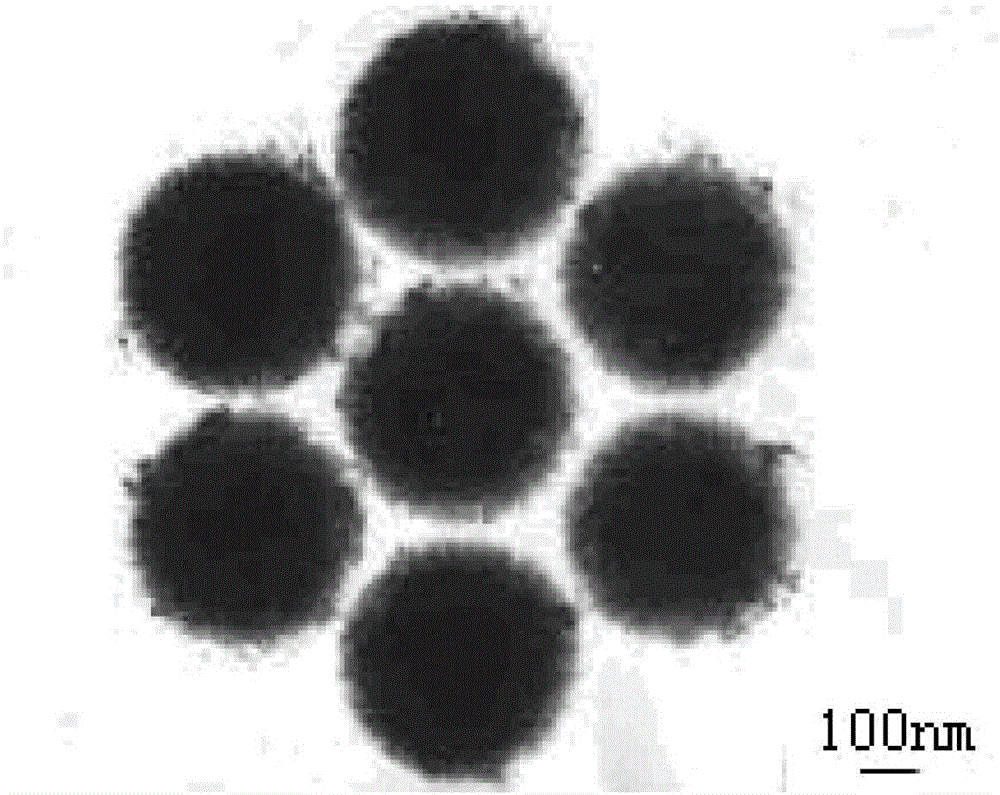

[0039] Save the IV step of step (3) in embodiment 1, other steps are all the same as embodiment 1, obtain Fe 3 o 4 / (PDDA / 30-SiO 2 ) 1 Composite microspheres, the thickness of the shell is about 60nm, and the thickness of the shell is smaller than that of Fe 3 o 4 / (PDDA / 30-SiO 2 ) 3 The shell thickness of the composite microsphere is small.

[0040] "Wastewater initial concentration is 15mg / L" is adjusted to "wastewater initial concentration is 100mg / L" in embodiment 2, and " the Fe that adds 100mg / L simultaneously 3 o 4 / (PDDA / 30-SiO 2 ) 3 Composite microspheres and 10mmoL / L of H 2 o 2 "Adjusted to" add 200mg / L of Fe at the same time 3 o 4 / (PDDA / 30nm-SiO 2 ) Composite microspheres and 50mmoL / L of H 2 o 2 ", other steps are the same as in Example 2.

[0041] After 1 hour of reaction, the removal rate of phenol has reached over 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com