Impact-resistant high-melt-index high-rigidity polypropylene composite material

A composite material, polypropylene technology, applied in the field of impact-resistant, high-melt index, and high-rigidity polypropylene composite materials, it can solve the problems that polypropylene's high melt index, high rigidity and impact resistance cannot be satisfied at the same time, and achieve high fluidity, durability Excellent impact performance and high melt index effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

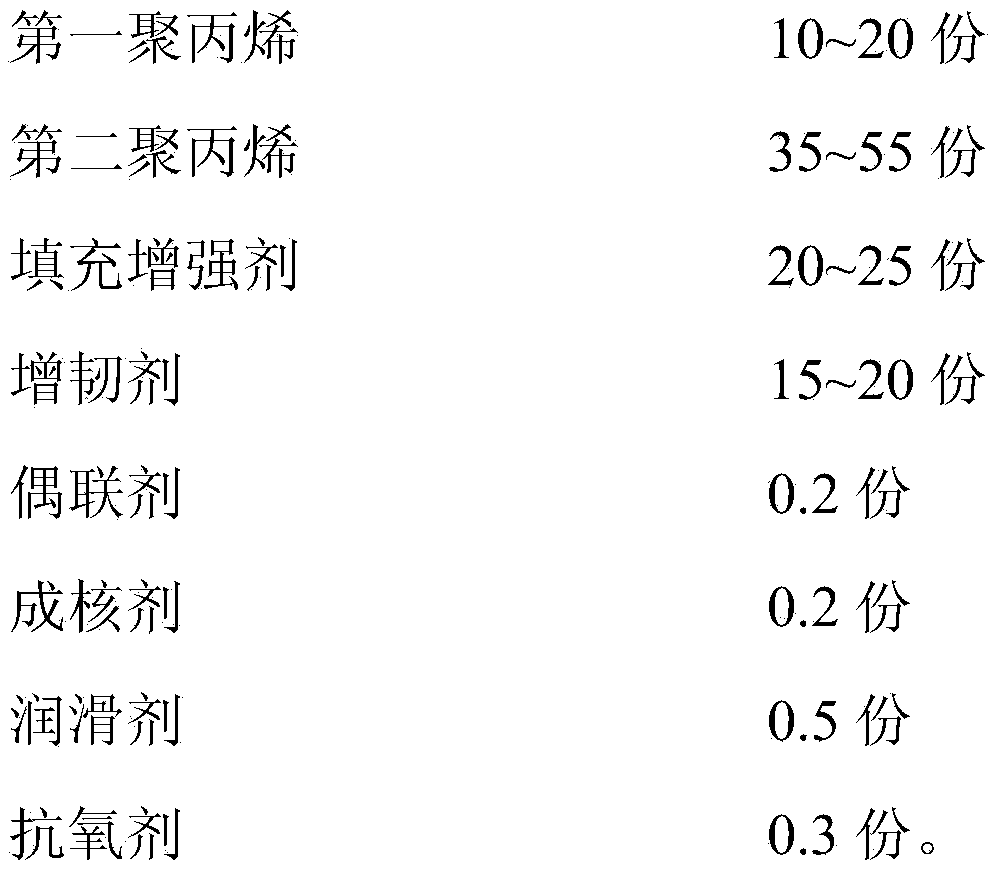

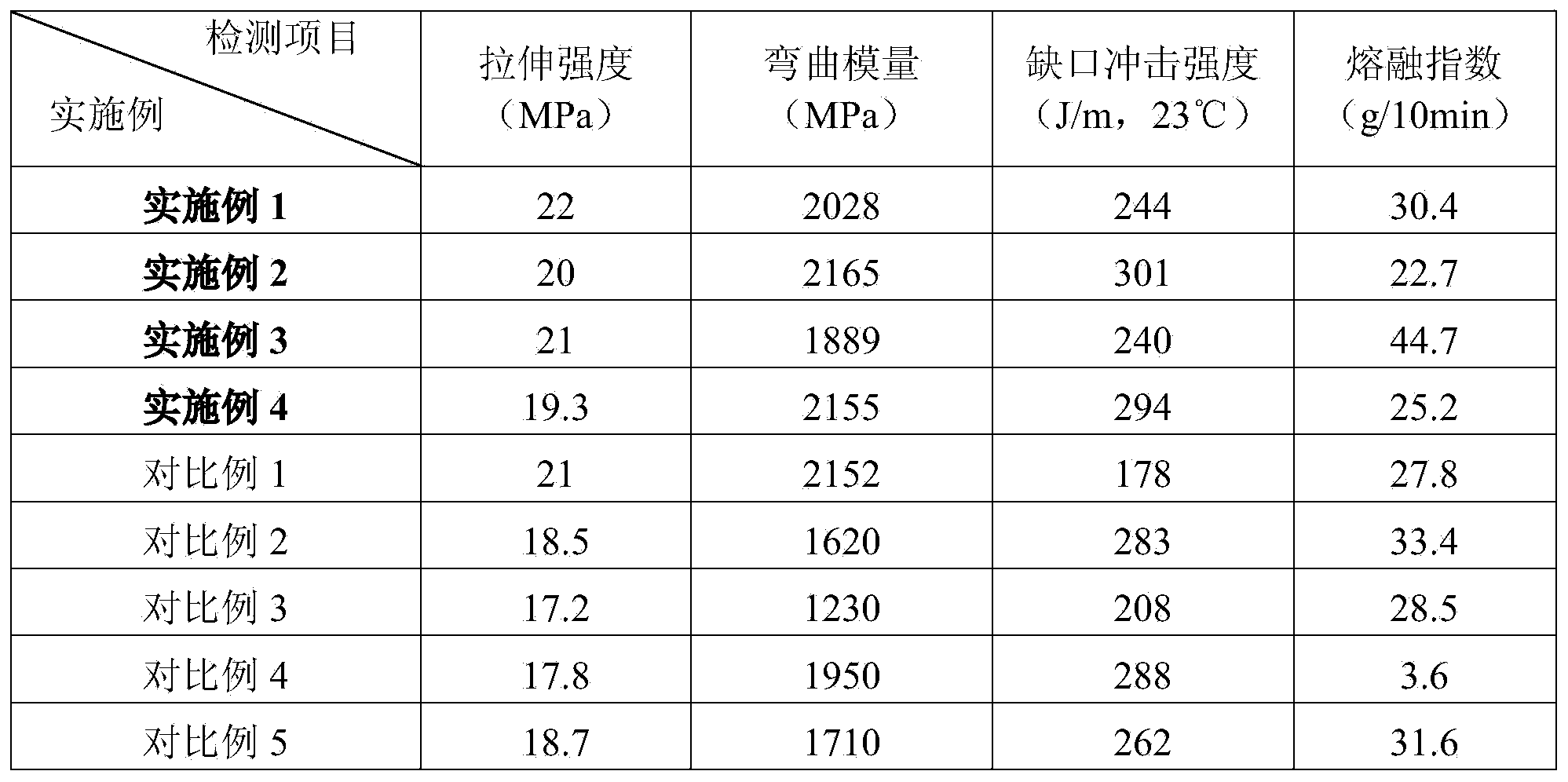

[0023] Prepare the raw materials of each mass parts shown in the following table 1:

[0024] Table 1

[0025] raw material name

parts by weight

K7726

12

K7760

53

filling enhancer

20

Toughener

15

coupling agent

0.2

Nucleating agent

0.2

0.5

0.3

[0026] In Table 1, K7726 is the medium melt index copolymer polypropylene produced by Sinopec Yanshan Branch, and its melt index is 30g / 10min; K7760 is the high melt index copolymer polypropylene produced by Sinopec Yanshan Branch, and its melt index is 60g / 10min; The filling enhancer is a mixture of ultrafine talc powder and fine talc powder with a mass ratio of 7:3, wherein the particle size of the ultrafine talc powder is D50=1.2 microns, D95=3.8 microns, and the loss after burning at 800°C for 2 hours rate≤3%, the particle size of fine talc powder is D50=3.0 microns, loss rate≤6% after burning at 800°C...

Embodiment 2

[0030] Prepare the raw materials of each mass parts shown in the following table 2:

[0031] Table 2

[0032] raw material name

parts by weight

K7726

18

[0033] K7760

37

filling enhancer

25

Toughener

20

coupling agent

0.2

Nucleating agent

0.2

0.5

0.3

[0034] The raw materials in Table 2 are the same as in Table 1 of Example 1.

[0035] The raw materials in Table 2 were processed according to the processing method of Example 1 to obtain the finished product of impact-resistant high-melting index high-rigidity polypropylene composite material.

Embodiment 3

[0037] Prepare the raw materials of each mass parts shown in the following table 3:

[0038] table 3

[0039] raw material name

parts by weight

K7726

10

K7100

55

filling enhancer

20

Toughener

15

coupling agent

0.2

Nucleating agent

0.2

0.5

antioxidant

0.3

[0040] In Table 3, K7100 is a high-melt index copolymer polypropylene produced by Sinopec Yanshan Branch, and its melt index is 110g / 10min; other raw materials are the same as those in Table 1 of Example 1.

[0041] The raw materials in Table 3 were processed according to the processing method of Example 1 to obtain the finished product of impact-resistant high-melting index high-rigidity polypropylene composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com