Low-melting-point biological nylon material and preparation method thereof

A nylon and biological technology, which is applied in the field of polymer material nylon synthesis, can solve problems such as reducing the melting point of nylon, multiphase coexistence and compatibility, and achieves the effects of low equipment cost, simple reaction steps and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

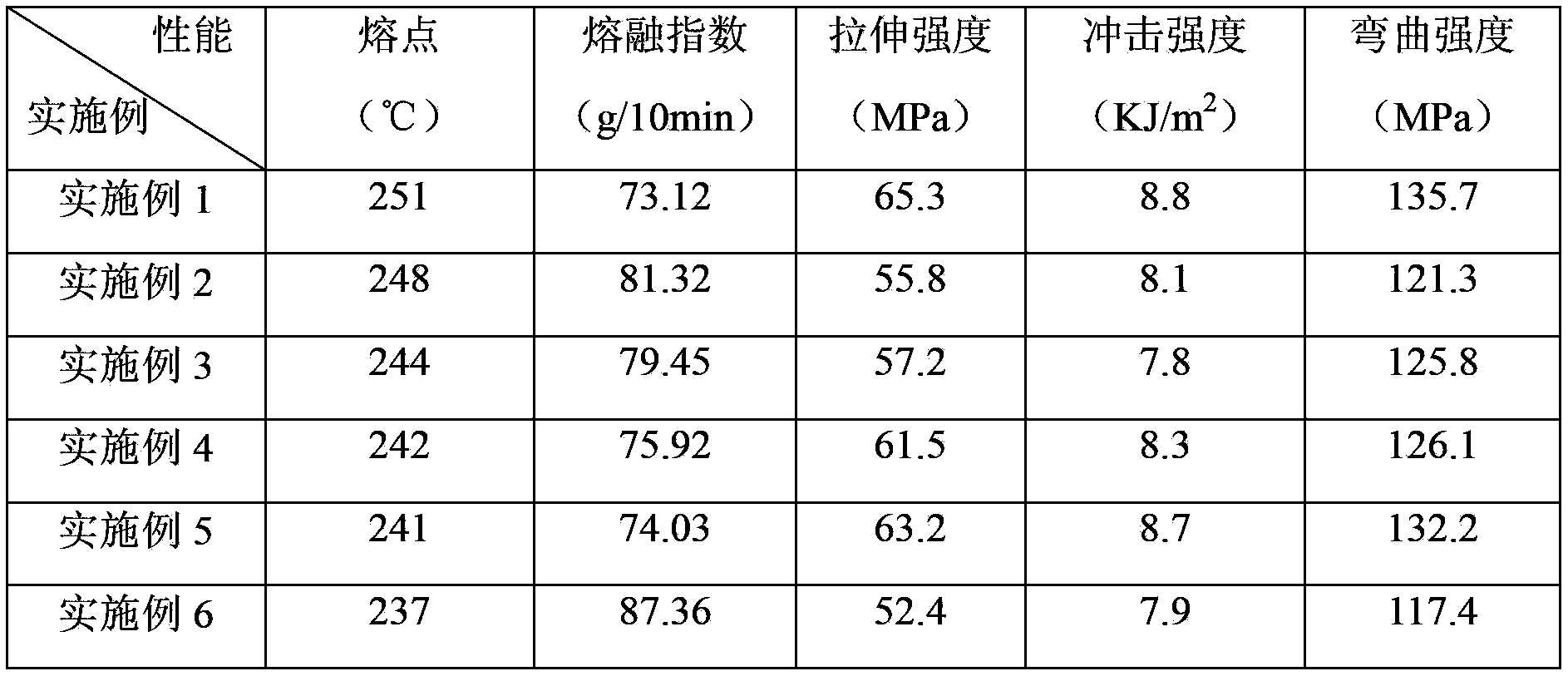

Examples

Embodiment 1

[0040] (1) Weigh 1495.17g (9.00mol) of terephthalic acid, 2224.75g (11.00mol) of sebacic acid, 2289.337g (19.70mol) of hexamethylenediamine, 1.2896g (0.015mol) of sodium hypophosphite, and mix Evenly pour it into a 25L reactor, inject 3.96kg of deionized water (220mol) and 101.34g of nucleating agent barium sulfate solution (8.06% by mass fraction, 0.035mol of barium sulfate) into the reactor, replace the pre- The air left in the reactor is at least three times, and 0.01MPa nitrogen is reserved as a protective gas.

[0041] (2) Heat the reactor at a rate of 15°C per minute by circulating heat transfer oil, and the temperature rises to 285°C. When the temperature of the reactor is 125°C, keep the inside of the reactor warm for 2 hours and at the same time the pressure is 2.5 At MPa, the pressure of the reactor is maintained by releasing the water vapor generated by the system reaction. The constant pressure time is 1 hour, and then the reactor is depressurized. During the proc...

Embodiment 2

[0044] (1) Weigh 1461.94g (8.80mol) of isophthalic acid, 2265.2g (11.20mol) of sebacic acid, 2539.1232g (19.20mol) of heptanediamine, 2.0414g (0.020mol) of potassium hypophosphite, and mix Evenly pour it into a 25L reactor, and inject 1151.75g of ethanol solution (250mol) into the reactor. And nucleating agent titanium dioxide solution 33.9494g (mass fraction 8.94%, 0.038mol titanium dioxide) in the reactor, replace the air in the reactor with helium at least three times, and reserve 0.02MPa helium as a protective gas.

[0045] (2) Heat up the reactor by circulating heat transfer oil at a rate of 12°C per minute, and the temperature rises to 280°C. When the temperature of the reactor is 125°C, keep the inside of the reactor warm for 2.2 hours, and at the same time the pressure is When the temperature is 2.5MPa, the pressure of the reactor is maintained by releasing the water vapor generated by the reaction of the system. The constant pressure time is 1.1 hours, and then the ...

Embodiment 3

[0048](1) Weigh 1428.72g (8.6mol) of phthalic acid, 2305.65g (11.40mol) of sebacic acid, 2784.218g (19.30mol) of octyldiamine, and 4.25g (0.025mol) of calcium hypophosphite, and mix them evenly and Pour it into a 25L reactor, inject 8.65kg of methanol (270mol) and 115.83g of nucleating agent barium sulfate solution (8.06% mass fraction, 0.04mol of barium sulfate) into the reactor, and replace it with nitrogen in the reactor The air inside is at least three times, and 0.03MPa nitrogen is reserved as a protective gas.

[0049] (2) Heat the reactor at a rate of 10°C per minute by circulating heat transfer oil, and the temperature rises to 282°C. When the temperature of the reactor is 125°C, the inside of the reactor is kept warm for 2 hours and the pressure is 2.5 At MPa, the pressure of the reactor is maintained by releasing the water vapor generated by the reaction of the system. The constant pressure time is 0.8 hours, and then the reactor is depressurized. During the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com