Method for synthesizing nano selenium material

A technology of nano-selenium and selenium powder, which is applied in the field of synthesis of nano-selenium materials, can solve the problem that selenium has no physiological function, and achieve the effects of low corrosion, short reaction steps, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

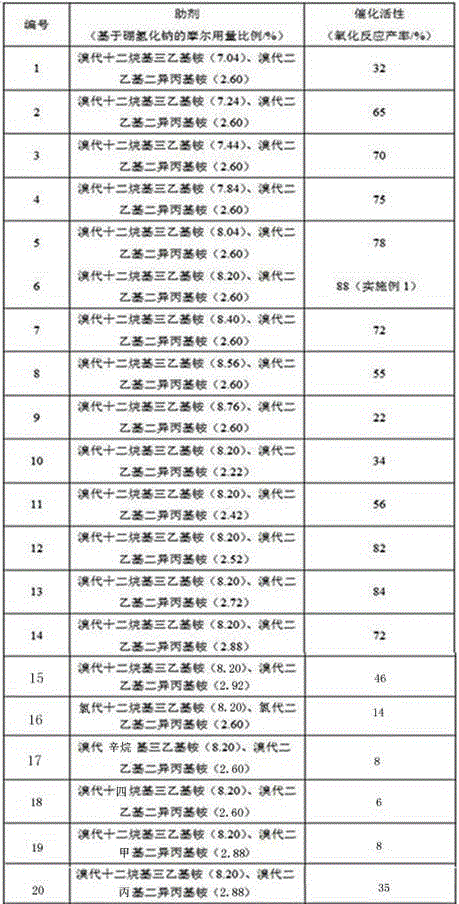

Embodiment 1

[0015] 1. The process of preparing nano-selenium materials: under cooling in an ice-water bath (ie 0±1°C), mix 20 mL of sodium borohydride ethanol solution with a concentration of 1 mol / L and 20 mmol of selenium powder (the molar dosage is 100% of sodium borohydride) Mix, then add 20 mmol of glucose (10 times the molar amount of sodium borohydride), dodecyltriethylammonium bromide (8.20% of the molar amount of sodium borohydride) and diethyldiisopropyl bromide A mixture of ammonium (the molar amount is 2.60% of that of sodium borohydride) was stirred at 30°C for 24 hours to obtain a precipitate, filtered, and then calcined at 500°C for 5 hours to obtain a nano-selenium material.

[0016] 2. Apply nano-selenium to olefin oxidation and test its catalytic activity.

[0017] The specific steps are: Dissolve 1 mmol of 1,1-diphenylethylene in 1 mL of acetonitrile, then add 10 mg of nano-selenium catalyst, add 2 mmol of hydrogen peroxide aqueous solution with a mass concentration of ...

Embodiment 2

[0018] Embodiment 2: other conditions are the same as embodiment 1, check the reaction of different concentrations of sodium borohydride, and the experimental results are shown in the following table 1.

[0019]

[0020] From the above results, it can be seen that when the reaction sodium borohydride concentration is 1.0 mol / L (Example 1), the yield of benzophenone is the highest, and it can be seen that the nano-selenium material has the strongest activity.

Embodiment 3

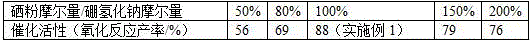

[0021] Embodiment 3: other conditions are the same as embodiment 1, check the reaction of different selenium powder consumptions, experimental result is as following table.

[0022]

[0023] As can be seen from the above results, when the selenium powder consumption is 100% (embodiment 1) of sodium borohydride molar weight, the effect is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com