Melting-expanded electret antibacterial master batch and processing technology and application thereof

An antibacterial masterbatch, electret technology, applied in the direction of single-component polyolefin rayon, chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of single function, high price, unable to meet the needs of the market, etc. Flow performance, improving melt index, effect of solving shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

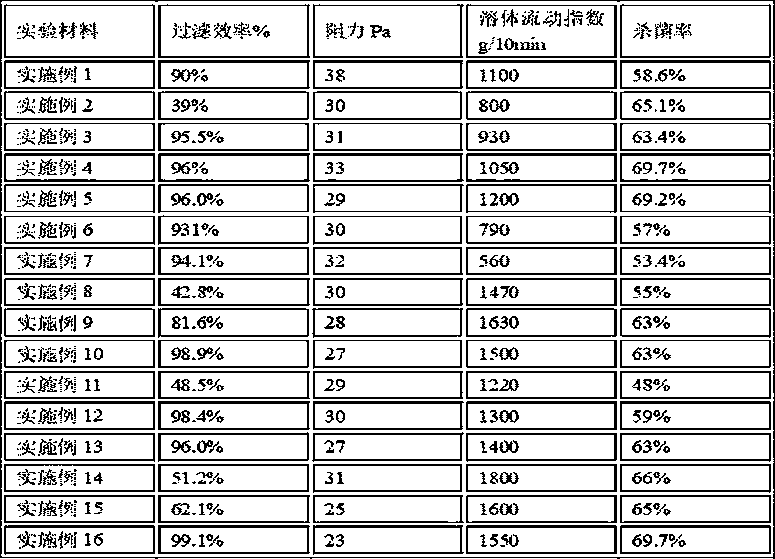

Examples

preparation example Construction

[0034] The preparation method of extended melt electret antibacterial masterbatch, heat polyethylene to 50 degrees Celsius, use a high-speed stirring pot to grind electret materials and peroxides, and blend plasticizers, lubricants, and antibacterial agents after the materials are ground , melt blending and extruding and granulating, and put into a twin-screw extruder with an aspect ratio of 48 to melt and extrude; the temperature of the melting section during melt blending and extrusion is 220 to 260 ° C, and granulate to dry the particles to obtain Extended fusion electret antibacterial masterbatch.

[0035] The use of expanded melt electret antibacterial masterbatch, adding 2 to 6% expanded melt electret antibacterial masterbatch to the fiber-grade PP raw material of Zhongrong Finger, can become a meltblown material for making medical mask meltblown cloth. Preferably, the proportion of the expanded melt electret masterbatch is 4%.

Embodiment 1

[0037] Heat 90 parts of PPY35 (homopolypropylene PPH) to 50 degrees Celsius, grind 2 parts of electret material tourmaline and 2 parts of peroxide DCP with a high-speed stirring pot, and grind 2 parts of the plasticized A semi-microcrystalline paraffin wax, 2 parts of lubricant stearic acid, 1 part of inorganic antibacterial agent are blended, melt blended, extruded and granulated, and melted and extruded in a twin-screw extruder with an aspect ratio of 48 ; The temperature of the melting section during melt blending and extrusion is 220-260 ° C, and the particles are dried by granulation to obtain the expanded melt electret masterbatch.

Embodiment 2

[0039] Heat 90 parts of PPY25 (homopolypropylene PPH) to 50 degrees Celsius, grind 2 parts of electret material graphene and 2 parts of peroxide 1010 with a high-speed stirring pot, and grind 1 part of the plasticized White oil, 0.5 part of lubricant zinc stearate and 0.5 part of antibacterial agent inorganic antibacterial agent are blended, melt blended and extruded and granulated, and put into a twin-screw extruder with an aspect ratio of 48 for melt extrusion out; the temperature of the melting section during melt blending and extrusion is 220-260°C, and the particles are dried by granulation to obtain an expanded-melt electret masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com