Formula and preparation method of high fluidity polyvinyl chloride alloy

A polyvinyl chloride and high fluidity technology is applied in the formulation and preparation field of polyvinyl chloride alloys, which can solve problems such as difficulty in meeting practical applications and use restrictions, and achieve the effects of low production cost, satisfying use requirements, and improving application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

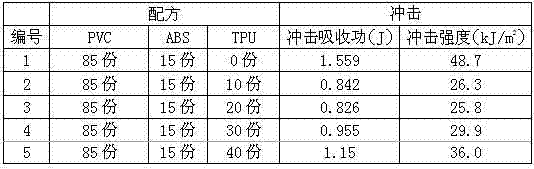

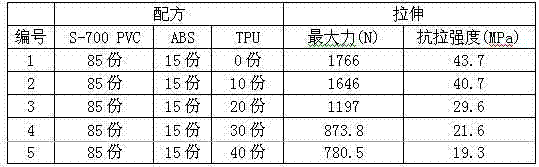

[0038] Example 1 of the present invention: A method for preparing a high-fluidity polyvinyl chloride alloy. 100 parts of polyvinyl chloride with a degree of polymerization of 700, 6 parts of organotin, 0.5 parts of stearic acid, 0.5 parts of PE wax, and 3 parts of citric acid Tributyl ester (equal parts by weight of trioctyl citrate, acetyl tributyl citrate or acetyl trioctyl citrate and other citric acid esters can also be used instead) to be blended by a high mixer at a speed of 1430r / min, discharging at 110°C to obtain a polyvinyl chloride material; 85 parts of the polyvinyl chloride material, 15 parts of ABS and 40 parts of TPU are added to the conical twin-screw extruder for melt extrusion, and the die The temperatures of zone three, die mouth zone two, mould mouth zone one, host zone three, host zone two and host zone one are 185℃, 180℃, 175℃, 170℃, 165℃ and 145℃ respectively; the host speed is 12rpm, The feeding speed is 7 rpm; the extruded material is cut into pellets,...

Embodiment 2

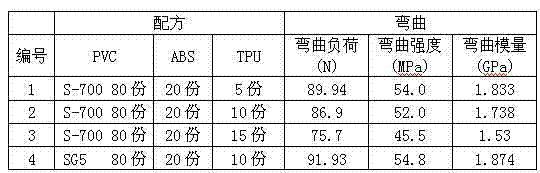

[0039] Example 2 of the present invention: a method for preparing a high-fluidity polyvinyl chloride alloy, 100 parts of polyvinyl chloride with a degree of polymerization of 800, 6 parts of calcium and zinc stabilizers, 0.5 parts of oxidized polyethylene wax, 0.5 parts of PE wax, and 3 parts A portion of 1,2-cyclohexane-diisopropyl dicarboxylate imported from Germany is blended by a high-mixer at a speed of 1430r / min and discharged at 110°C to obtain a polyvinyl chloride material; 80 parts of vinyl chloride material, 20 parts of MBS and 5 parts of TPU are added to the conical twin-screw extruder for melt extrusion. The die has three zones, two zones, one zone, three zones, and two zones. And the temperature in the first zone of the main engine are respectively 185℃, 180℃, 175℃, 170℃, 165℃, 145℃; the rotation speed of the main engine is 12rpm, and the feeding speed is 7rpm; then the extruded material is cut into pellets, and finally the finished polychloride is obtained. Vinyl ...

Embodiment 3

[0040] Example 3 of the present invention: the preparation method of high-fluidity polyvinyl chloride alloy, 100 parts of polyvinyl chloride with a degree of polymerization of 1000, 3 parts of organotin, 3 parts of rare earth stabilizers, 0.5 parts of stearic acid, and 0.5 parts of PE wax Parts and 3 parts of DOP are blended through a high-mixer at a speed of 1430r / min and discharged at 110°C to obtain a polyvinyl chloride material; 85 parts of this polyvinyl chloride material is mixed with 15 parts of ABS and 20 parts of TPU Join the conical twin-screw extruder for melt extrusion. The temperatures of the die mouth three zone, die mouth two zone, die mouth one zone, main machine three zone, main machine two zone and main machine one zone are respectively 185℃, 180℃, 175 ℃, 170℃, 165℃, 145℃; the main engine speed is 12rpm, and the feeding speed is 7rpm; then the extruded material is cut into pellets, and finally the finished PVC alloy is obtained. The polyvinyl chloride alloy ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com