High-performance low-cost ABS/PET alloy material

An alloy material and low-cost technology, applied in the field of ABS/PET alloy materials, can solve the problems of increased material cost, limited application, expensive compatibilizers and impact modifiers, etc., to achieve improved melt index, small size, effective The effect that is beneficial to the performance of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

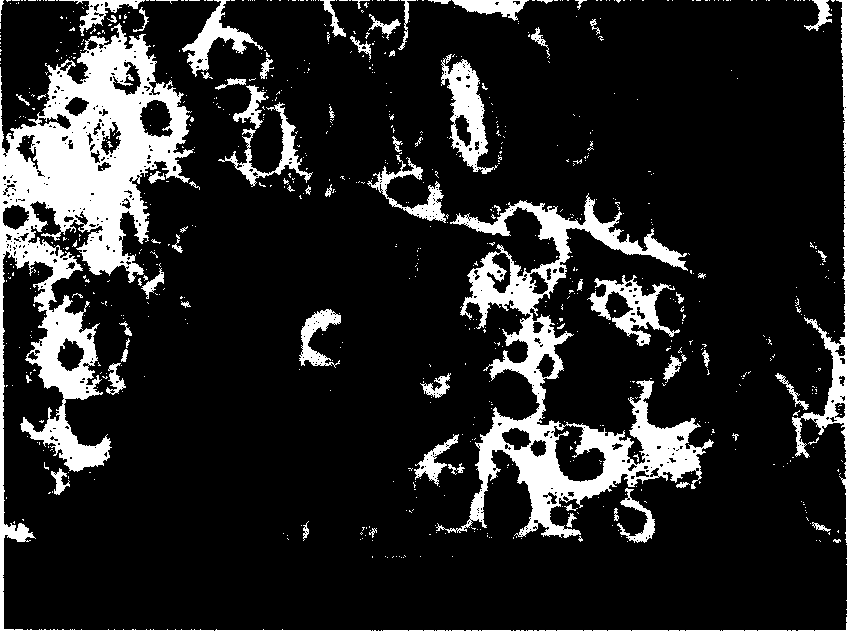

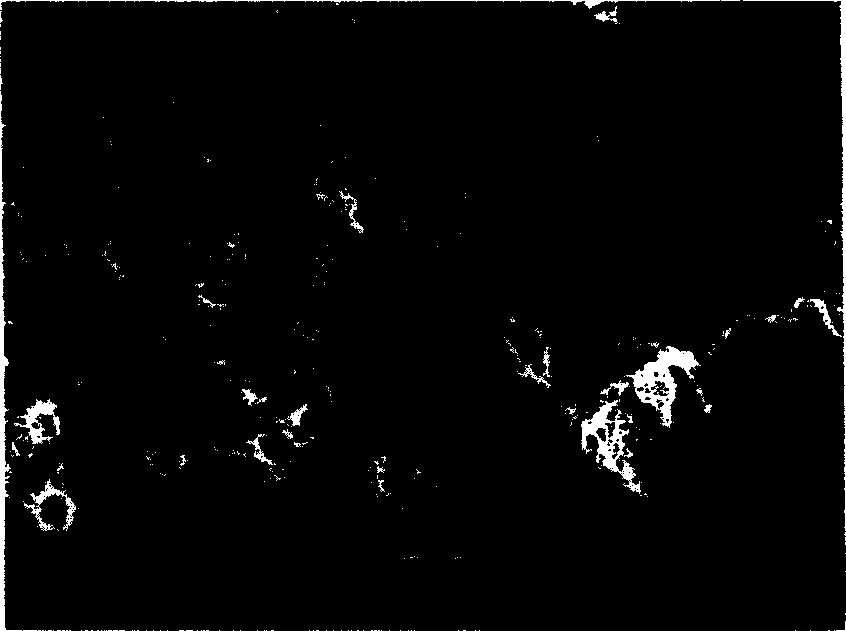

Image

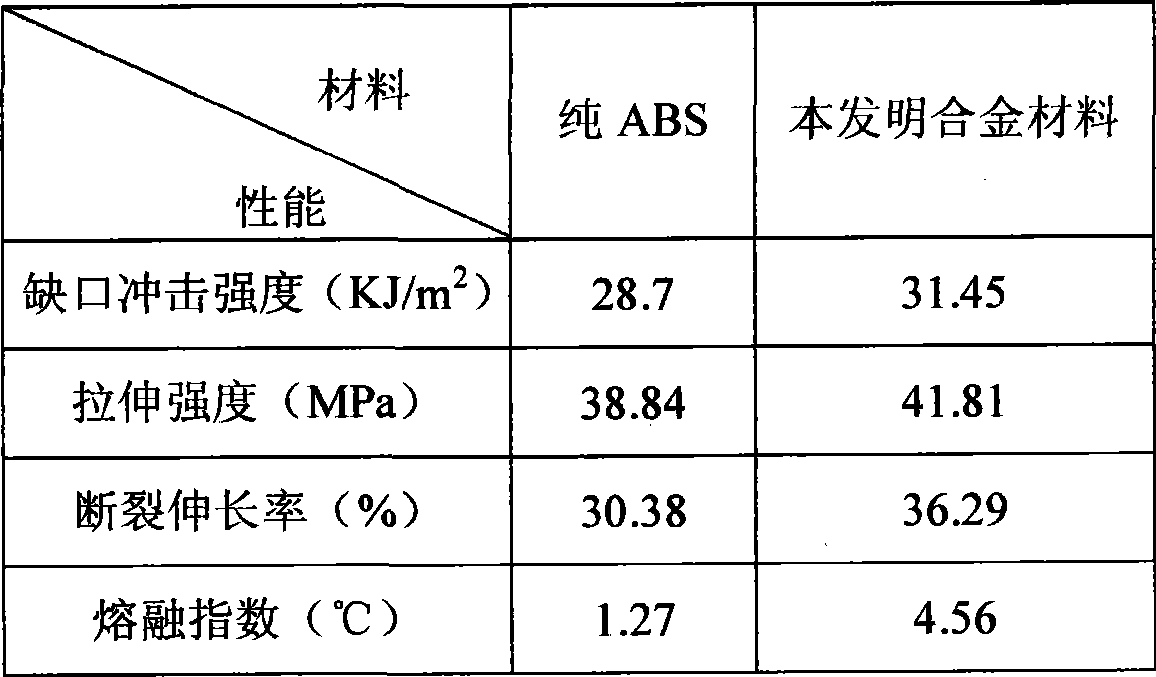

Examples

Embodiment 1

[0023] 90% ABS, 10% PET regrind by weight percentage, and 0.72% compound antioxidant by their total weight were first put into a high-speed mixer with a rotation speed of about 1000rpm and mixed for 5 minutes, and then Put it into a twin-screw extruder, extrude and granulate under the conditions of a processing temperature of 170-220°C and a screw speed of 900 rpm. The compound antioxidant is composed of 1010 and DLTP at a ratio of 1:3 by weight.

Embodiment 2

[0025] Be 80% ABS by weight percentage, 20% PET return material, and be 0.64% compound antioxidant by their gross weight first put into the high-speed mixer that rotating speed is about 1000rpm and mix 5 minutes, then Put it into a twin-screw extruder, extrude and granulate under the conditions of a processing temperature of 170-220°C and a screw speed of 900 rpm. The compound antioxidant is composed of 1010 and DLTP at a ratio of 1:3 by weight.

Embodiment 3

[0027] Be 70% ABS by weight percentage, 30% PET return material, and put into the high-speed mixer that rotating speed is about 1000rpm and mix 5 minutes first with their total weight of 0.56% compound antioxidant, and then Put it into a twin-screw extruder, extrude and granulate under the conditions of a processing temperature of 170-220°C and a screw speed of 900 rpm. The compound antioxidant is composed of 1010 and DLTP at a ratio of 1:3 by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com