Argil-modified low-smoke zero-halogen power cable sheath material and preparation method thereof

A technology of power cable and sheath material, which is applied in the direction of insulated cables, cables, circuits, etc., and can solve problems such as public safety hazards, leakage, and environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The cable material prepared by the present invention can pass the JB / T10707 standard.

[0046] In addition, the cable obtained by the cable material prepared by the present invention passes the flame retardancy of the bundled type C in IEC60332-3-24.

Embodiment approach

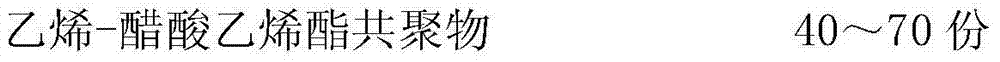

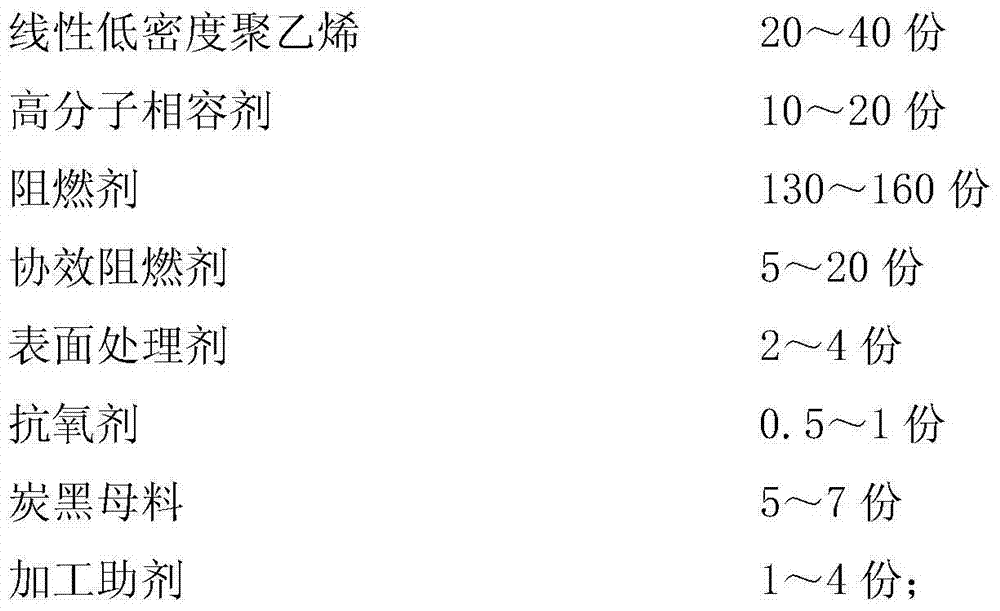

[0074] A clay-modified low-smoke halogen-free power cable sheathing material, which comprises the following components in mass fraction:

[0075]

[0076] in:

[0077] The clay-modified low-smoke halogen-free power cable sheathing material, the ethylene-vinyl acetate copolymer has a vinyl acetate content of 20-40% by mass and a melt index of 3-7g / min.

[0078] The clay-modified low-smoke halogen-free power cable sheathing material, the polymer compatibilizer is maleic anhydride grafted EPDM rubber, maleic anhydride grafted polyethylene or maleic anhydride One or two of grafted ethylene-vinyl acetate copolymers.

[0079] In the clay-modified low-smoke halogen-free power cable sheathing material, the flame retardant is one or more of aluminum hydroxide, magnesium hydroxide or barium sulfate.

[0080] In the clay-modified low-smoke halogen-free power cable sheathing material, the synergistic flame retardant is one or more of zinc oxide, clay, and montmorillonite.

[0081]...

Embodiment

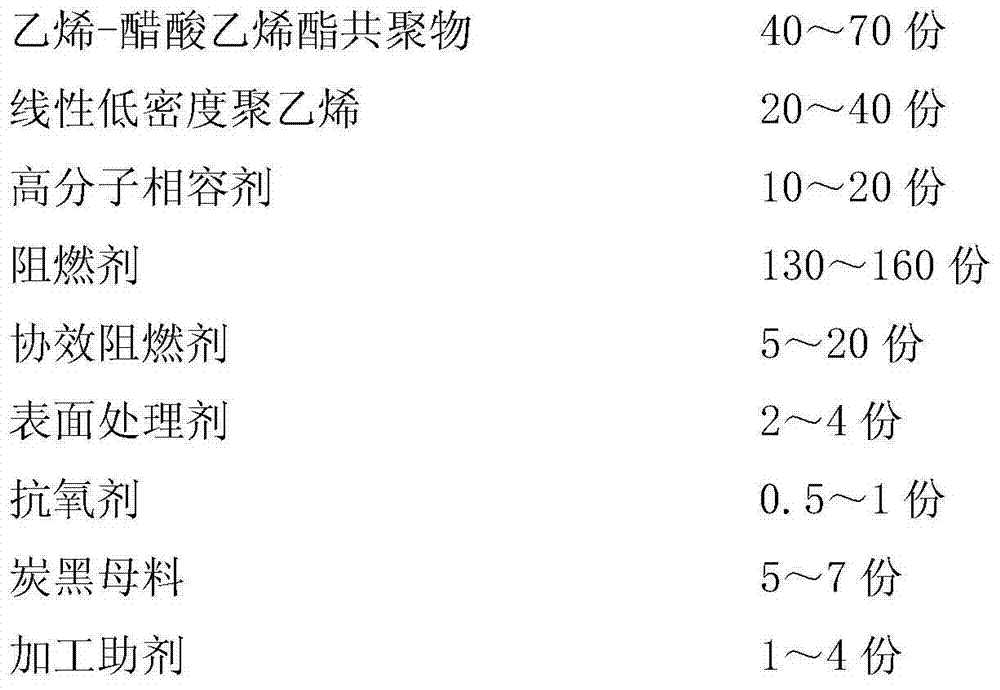

[0094] The raw material formulations of the embodiments of the present invention and comparative examples are shown in Table 1.

[0095] Table 1 The low-smoke halogen-free power cable sheath material embodiment and comparative ratio formula (number of parts)

[0096]

[0097] in:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com