Manufacturing method of composite package

A composite packaging bag and a manufacturing method technology, applied in the field of packaging bag manufacturing, can solve the problems of high energy loss, high coating temperature, insufficient surface flatness of the packaging bag, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

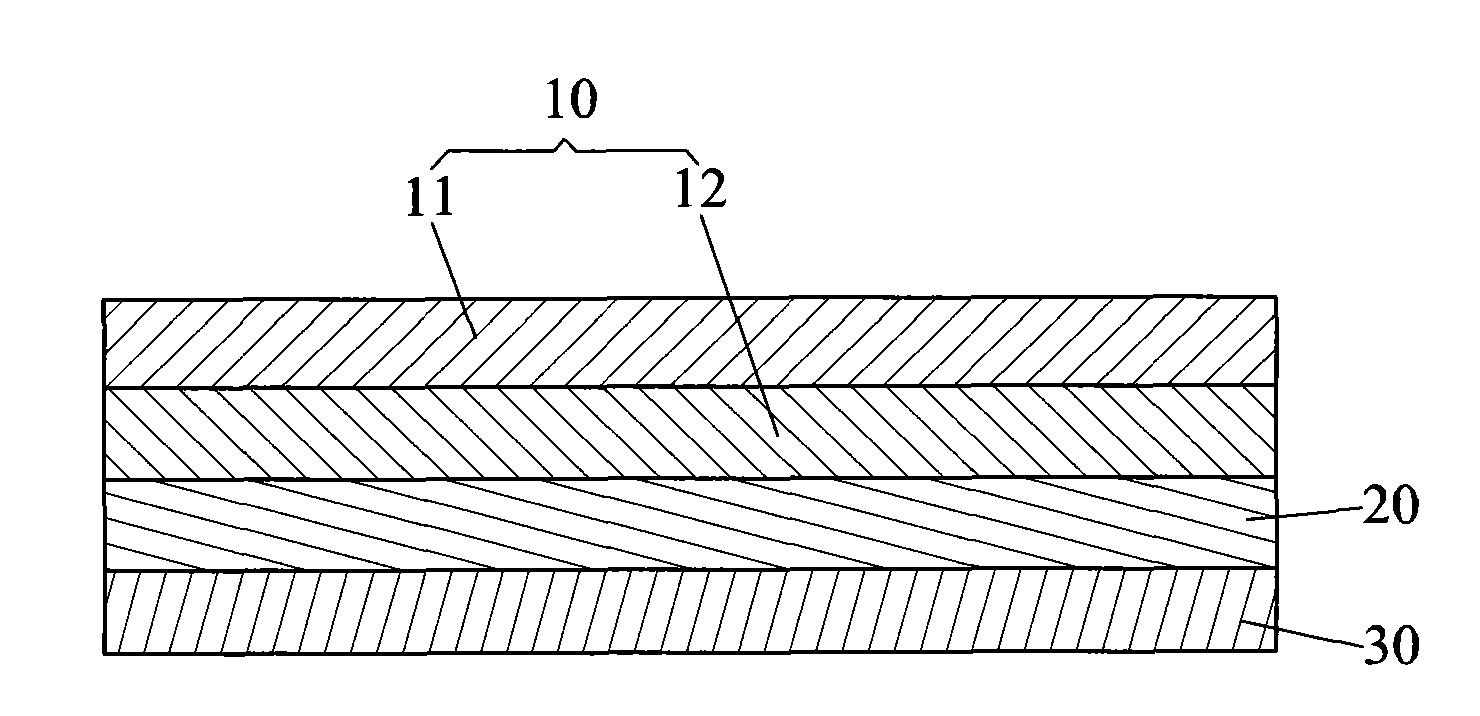

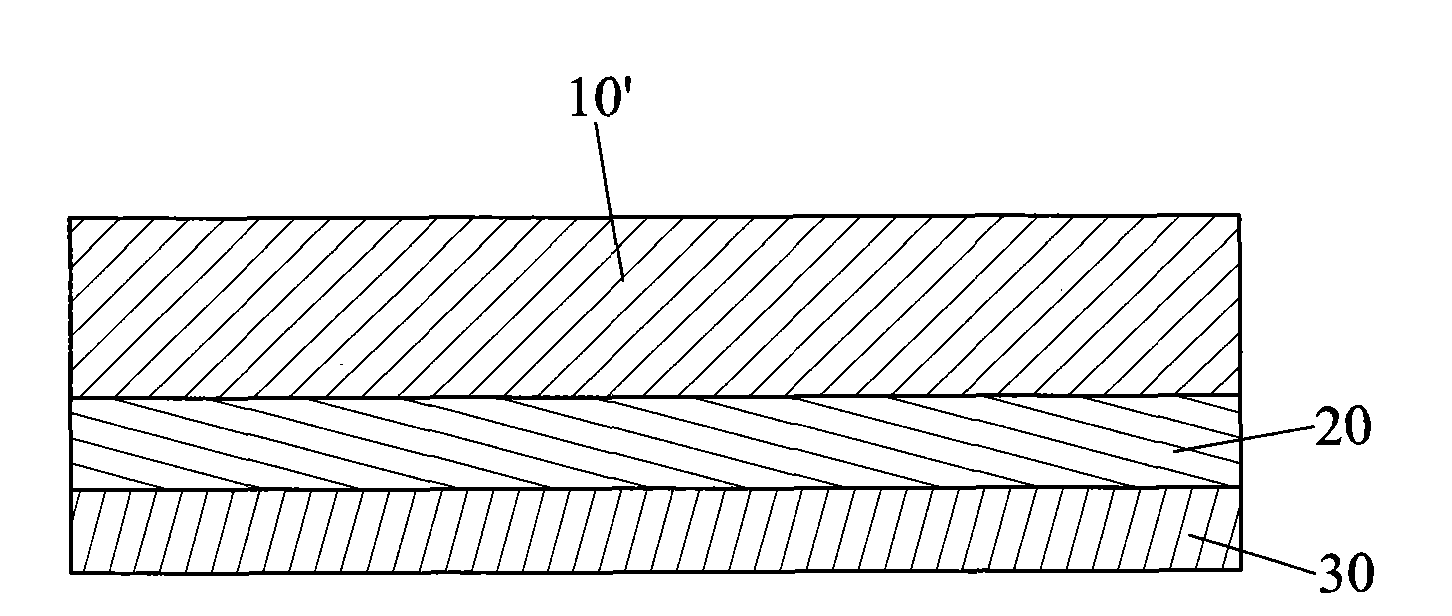

[0016] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

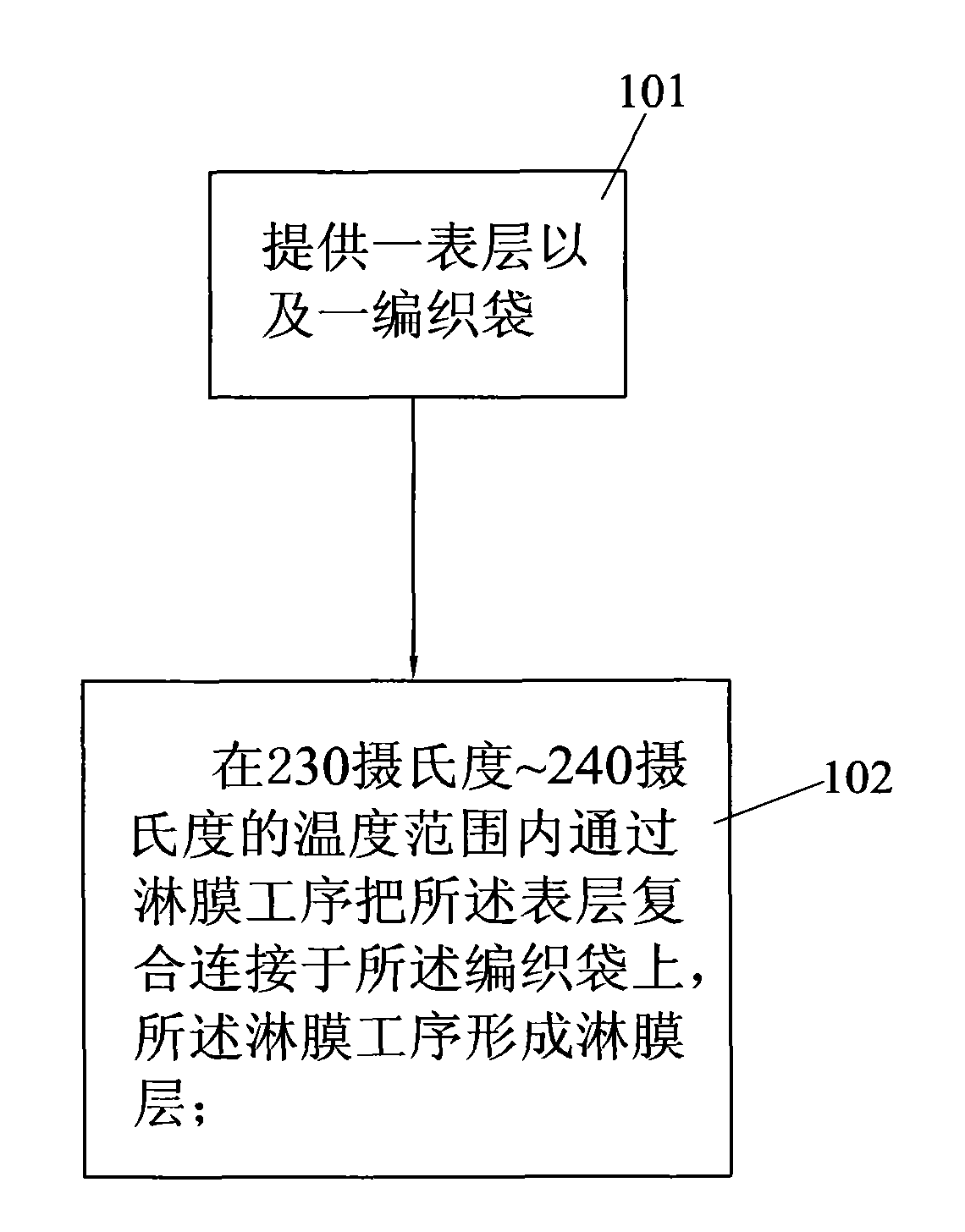

[0017] refer to figure 1 The present invention provides a method for manufacturing a composite packaging bag, which includes step 101 and step 102 in sequence. Step 101: Provide a surface layer and a woven bag. Step 102: Compositely connecting the surface layer to the woven bag through a coating process within a temperature range of 230 degrees Celsius to 240 degrees Celsius, and the coating process forms a coating layer.

[0018] Preferably, the coating material includes modified polypropylene and special polyethylene for coating, and the polypropylene contains molecular regulators and other safety aids, which increases the melt index of the coating material and improves its flow It helps to achieve lamination at a lower temperature, and make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com