Heat-insulating, anti-freezing and waterproof roll material and preparation method

A technology of waterproof coiled material and heat insulation layer, which is applied in the direction of chemical instruments and methods, lamination, coating, etc., can solve the problems of poor waterproof effect, troublesome construction process, and affect the waterproof effect of the service life, so as to achieve good coating Covering adhesion effect and waterproof performance, good heat insulation and antifreeze effect and elasticity, excellent waterproof and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

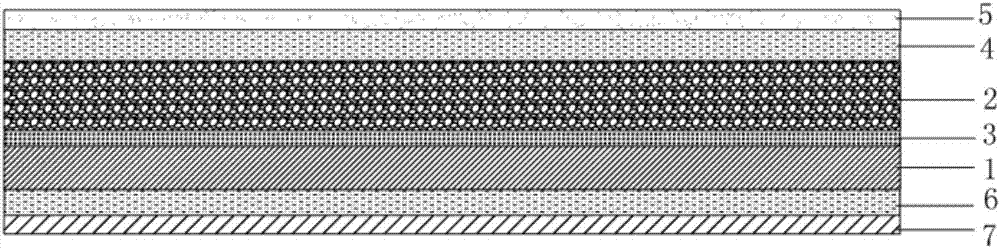

[0027] Such as figure 1 Shown, a kind of thermal insulation antifreeze waterproof roll material and preparation method of the preferred embodiment of the present invention;

[0028] The heat-insulating, anti-freeze and waterproof coiled material comprises a base material layer 1, the base material layer 1 is a glass fiber felt layer, and also includes a heat-insulating layer 2 arranged on the upper surface of the glass fiber felt layer, and the glass fiber felt layer The layer 1 and the heat insulating layer 2 are connected by an adhesive layer 3, the upper surface of the heat insulating layer 2 is provided with a first waterproof layer 4, and the upper surface of the first waterproof layer 4 is provided with a heat insulating coating 5, so The lower surface of the glass fiber felt layer 1 is also provided with a second waterproof layer 6 , and the lower surface of the second waterproof layer 6 is provided with a protective layer 7 .

[0029] The heat insulation layer 2 is a ...

Embodiment 2

[0033] A heat-insulating, anti-freezing, and waterproof coiled material of a preferred embodiment of the present invention and its preparation method;

[0034] The heat-insulating anti-freezing and waterproof coiled material includes a base material layer, the base material layer is a glass fiber felt layer, and also includes a heat-insulating layer arranged on the upper surface of the glass fiber felt layer, the glass fiber felt layer and the insulating layer The heat layers are connected by an adhesive layer, the upper surface of the heat insulation layer is provided with a first waterproof layer, the upper surface of the first waterproof layer is provided with a heat insulation coating, and the lower surface of the glass fiber felt layer is also provided with The second waterproof layer, the lower surface of the second waterproof layer is provided with a protective layer.

[0035]The heat insulation layer is a nano-material modified EVA foam layer, which not only inherits t...

Embodiment 3

[0039] The structure of the heat-insulating antifreeze and waterproof coiled material of the present invention is the same as that of Example 1, and the difference is its preparation method, which is as follows:

[0040] Coat a layer of graphene-modified EVA foam glue adhesive layer on the upper surface of the glass fiber mat, and then bond the heat insulation layer on the upper surface of the adhesive layer. The thickness of the heat insulation layer is 5 mm, and then apply Coating a graphene-modified epoxy resin layer, the thickness of the modified epoxy resin layer is 0.6 mm, and then coating the thermal insulation coating on the upper surface of the epoxy resin layer, the thickness is 0.3 mm; the lower surface of the glass fiber mat is coated with A graphene-modified epoxy resin layer with a thickness of 0.8 mm, and then bond a PE protective film on the lower surface of the epoxy resin layer to obtain the heat-insulating, antifreeze, and waterproof coiled material.

[0041...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com