Shoe producing and processing device

A processing device and a technology for shoes, which are applied in the direction of footwear, gluing shoe parts, shoe-making machinery, etc., can solve problems such as pressing that cannot prevent shoes from springing back, shoes being glued, and high frequency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

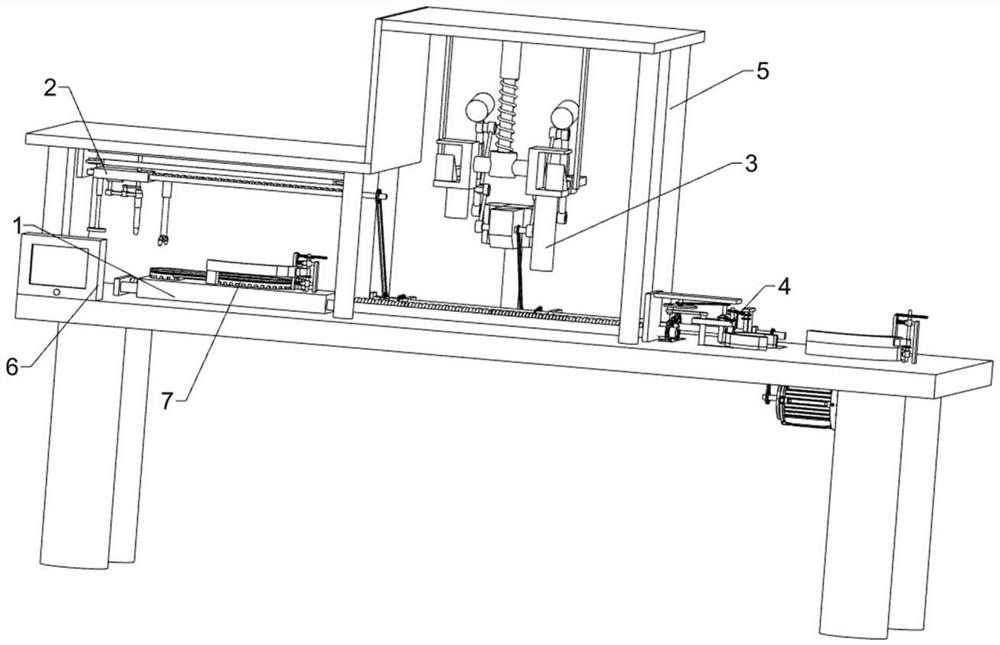

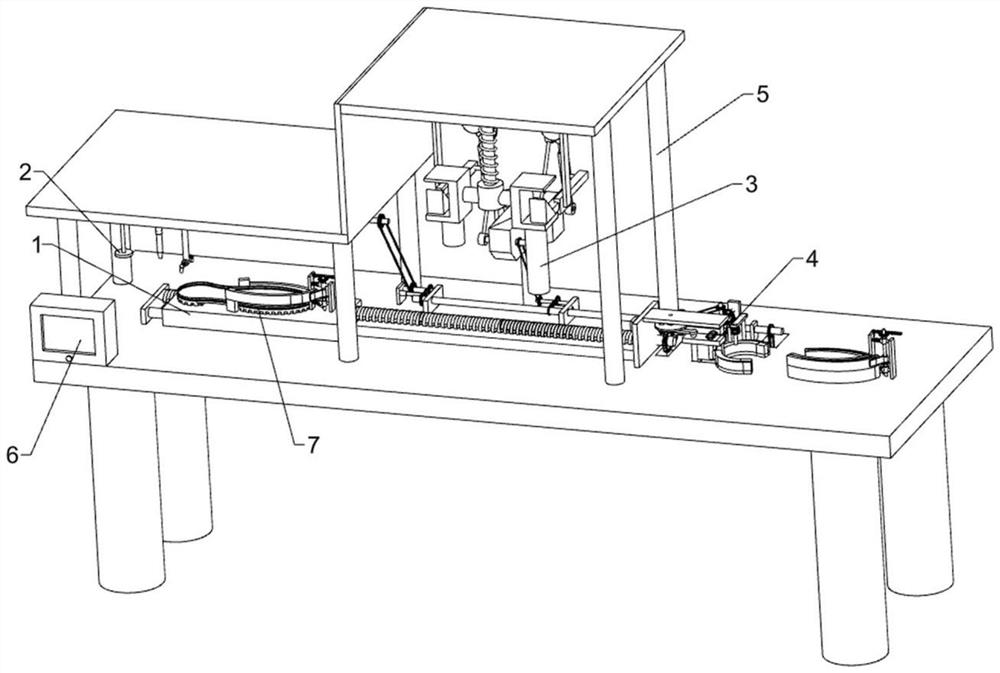

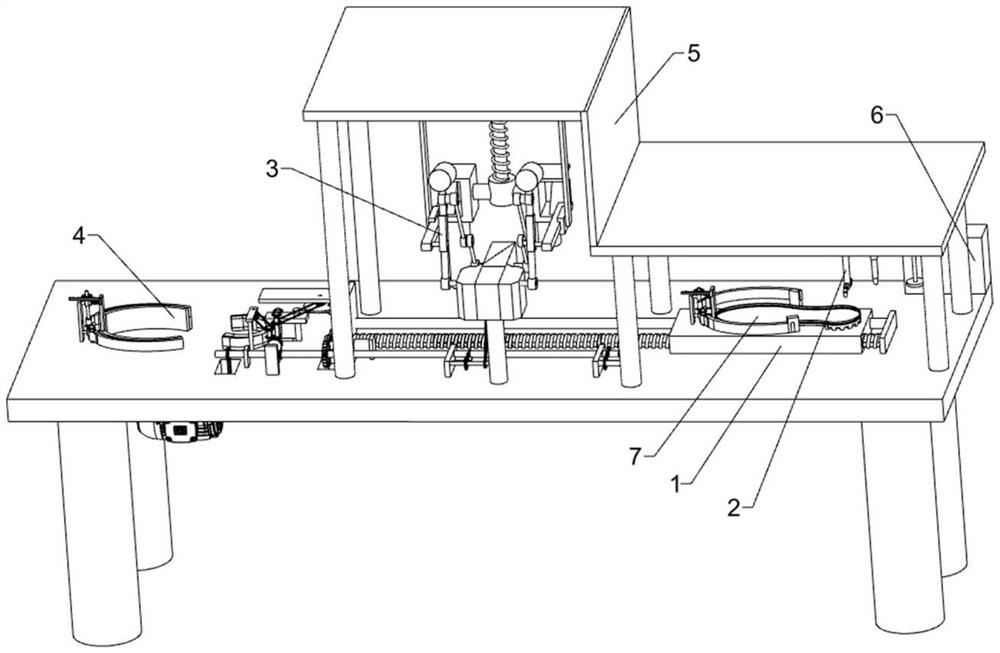

[0031] A shoe production and processing device, such as Figure 1-9 As shown, it includes a positioning transmission mechanism 1, a gluing heating mechanism 2, a secondary pressing mechanism 3, a side pressing mechanism 4, a workbench 5, a control display screen 6 and a sole 7; the workbench 5 is connected to the positioning transmission mechanism 1; The workbench 5 is connected with the gluing heating mechanism 2; the workbench 5 is connected with the secondary pressing mechanism 3; the workbench 5 is connected with the side pressing mechanism 4; the workbench 5 is connected with the control display screen 6; the positioning transmission mechanism 1 It is connected with the secondary pressing mechanism 3; the gluing heating mechanism 2 is connected with the secondary pressing mechanism 3; the secondary pressing mechanism 3 is connected with the side pressing mechanism 4. When the device is in use, the operation of various mechanisms is controlled by the control display screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com