Dip-type heater

A heater and immersion-type technology, applied in the direction of immersion heating device, heating element shape, etc., can solve the problems of heating element deformation, heating element contact, easy to be pressed by the inner wall of the protective tube, etc., and achieve the effect of avoiding burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

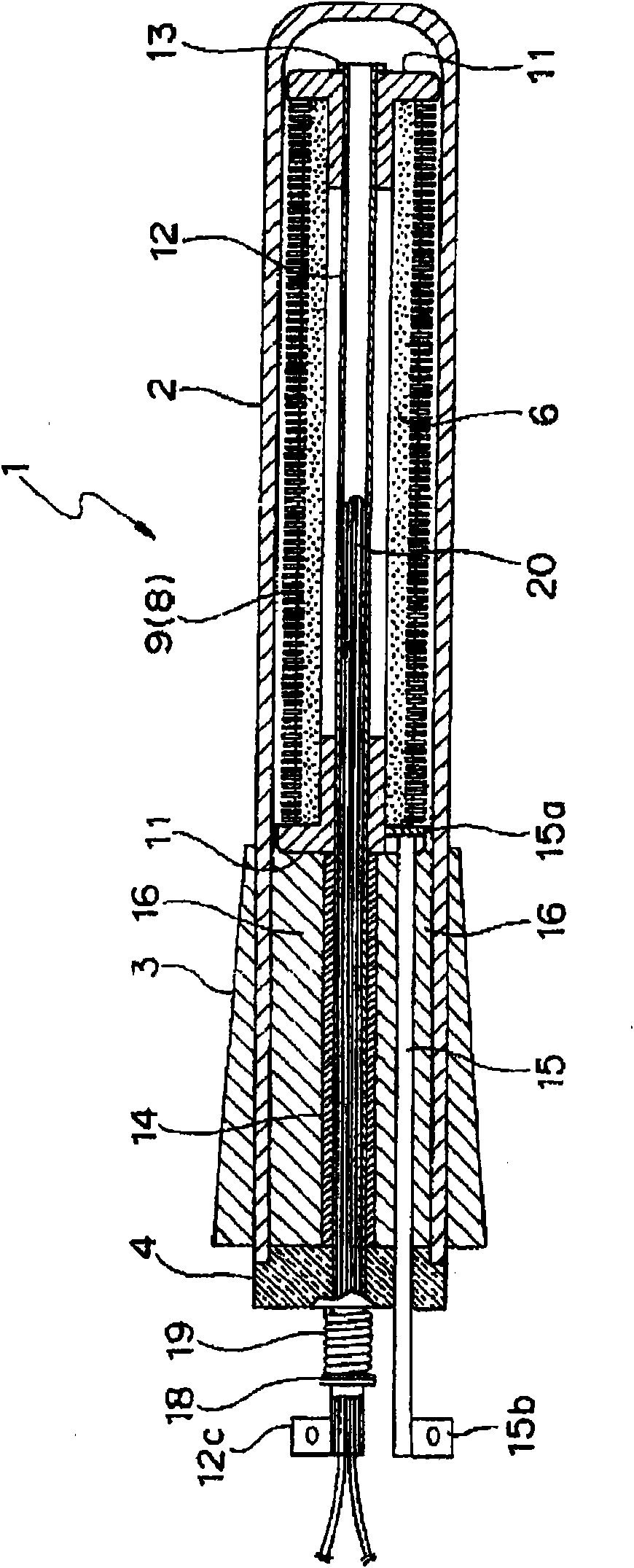

[0056] Embodiments of the present invention will be described below with reference to the drawings.

[0057] figure 1 It is a sectional view in the longitudinal direction (axial direction) of the immersion heater 1 according to one embodiment of the present invention. In addition, when describing the immersion heater 1, for the sake of convenience, the end on the side inserted into the furnace when it is installed in the furnace is referred to as the "front end", and the end on the opposite side is referred to as the "rear end". ".

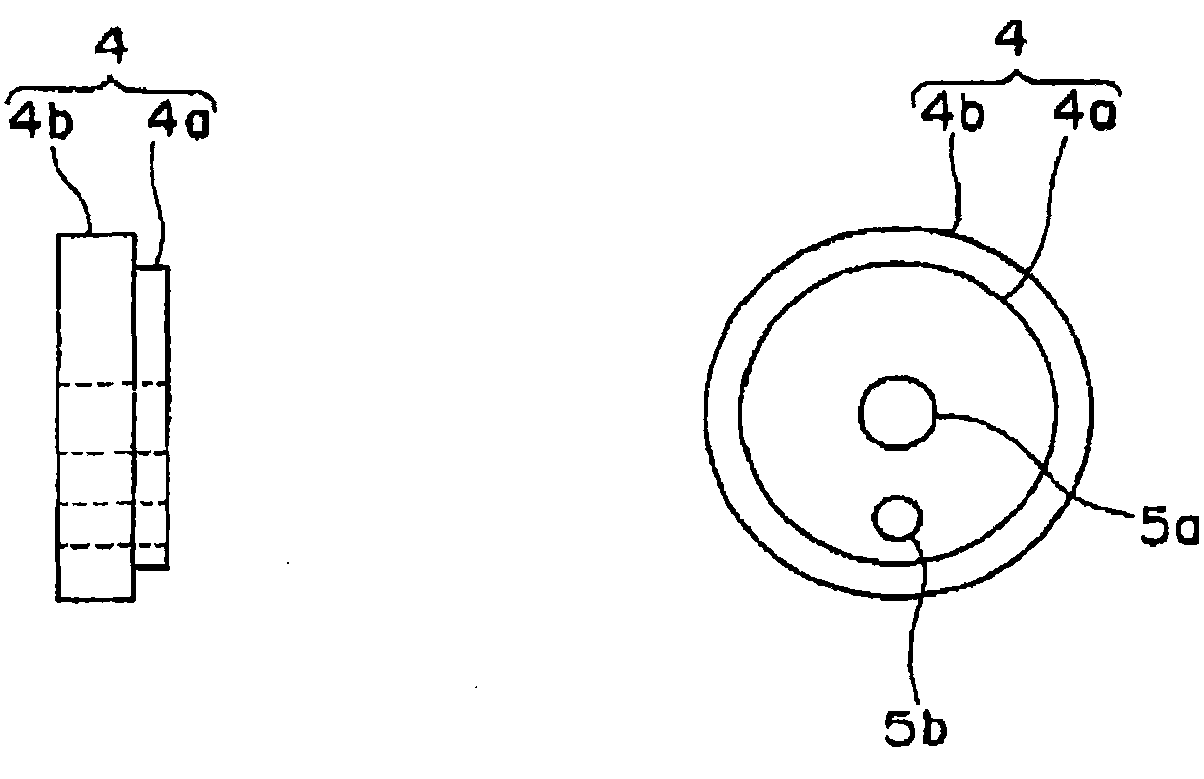

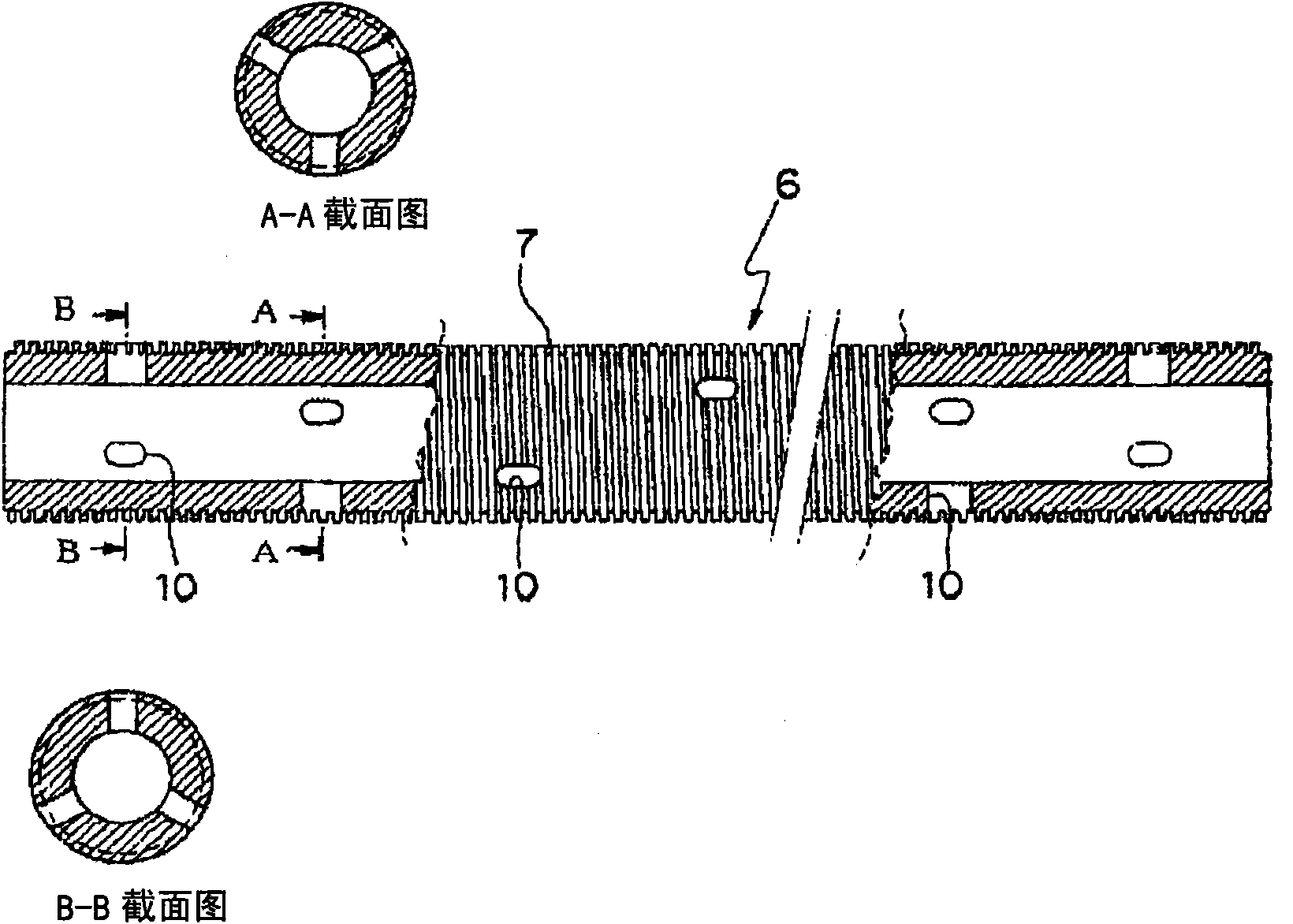

[0058] The immersion heater 1 includes a protection tube 2 made of ceramics. The protection tube 2 is made of silicon nitride-based precision ceramics, and forms a bottomed cylindrical body whose front end is closed and the other end is open. The tapered member 3 is fixed to the outer peripheral portion of the rear end portion of the protection tube 2 so as to form a part of the protection tube 2 . The tapered member 3 is made of ceramics simila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com