Colorful explosion-proof membrane

An anti-explosion film and colorful technology, applied in the direction of film/flaky adhesives, coatings, reflective/signal coatings, etc., can solve the problems of easy degumming, affecting costs, affecting service life, etc., to improve the use effect and service life, simplify the production process, and ensure the effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

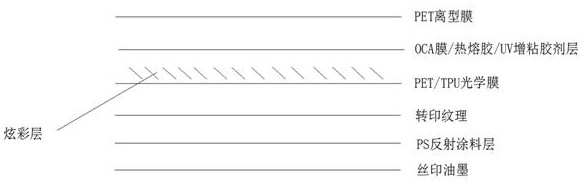

[0021] A colorful explosion-proof film, including a TPU layer optical film with a thickness of 45 μm, coated with a self-aligned liquid crystal colorful layer and a PS reflective coating layer on the upper and lower surfaces, and the thickness of the colorful layer or PS reflective coating is 3 μm respectively , 3μm, the light transmittance of the colorful layer and the PS reflective coating are 65% and 85% respectively, and the specific band reflectances of the two are 80% and 90% respectively, which are used to show different colors; the upper surface of the colorful layer is coated There is a PET release film with a thickness of 35 μm, and a hot-melt film is coated between the PET release film and the colorful layer. The thickness of the hot-melt film is 25 μm, and the peeling force is 50 N / in. At the same time, between the optical film and the reflective coating layer The transfer texture is set between them, and the transfer texture is UV transfer pattern to further improv...

Embodiment 2

[0023] A colorful explosion-proof film, including a PET layer optical film with a thickness of 40 μm, coated with a self-aligned liquid crystal colorful layer and a PS reflective coating layer on the upper and lower surfaces, and the thickness of the colorful layer or PS reflective coating is 2 μm respectively , 3μm, the light transmittance of the colorful layer and the PS reflective coating are 60% and 80% respectively, and the specific band reflectances of the two are 75% and 90% respectively, which are used to show different colors; the upper surface of the colorful layer is coated There is a PET release film with a thickness of 30 μm, and an OCA optical film is coated between the PET release film and the colorful layer. The thickness of the OCA optical film is 20 μm, and the peeling force is 45 N / in. The transfer texture is set between them. The transfer texture is UV transfer pattern to further improve the absorption effect on ultraviolet rays. The PS reflective coating la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com