Buffering device for producing optical cables

A buffer device and optical cable technology, which is applied in transportation and packaging, thin material handling, function indication, etc., can solve problems such as unbalanced metal belt tension, affecting optical cable production and product quality, and achieves the effect of avoiding excessive instantaneous force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

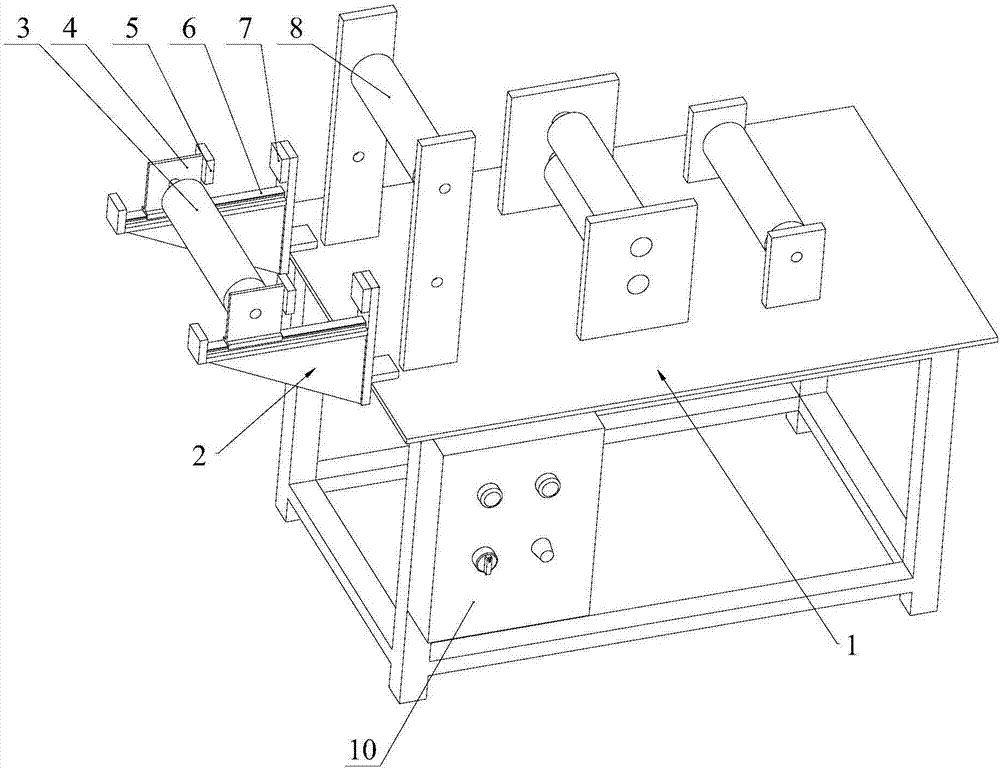

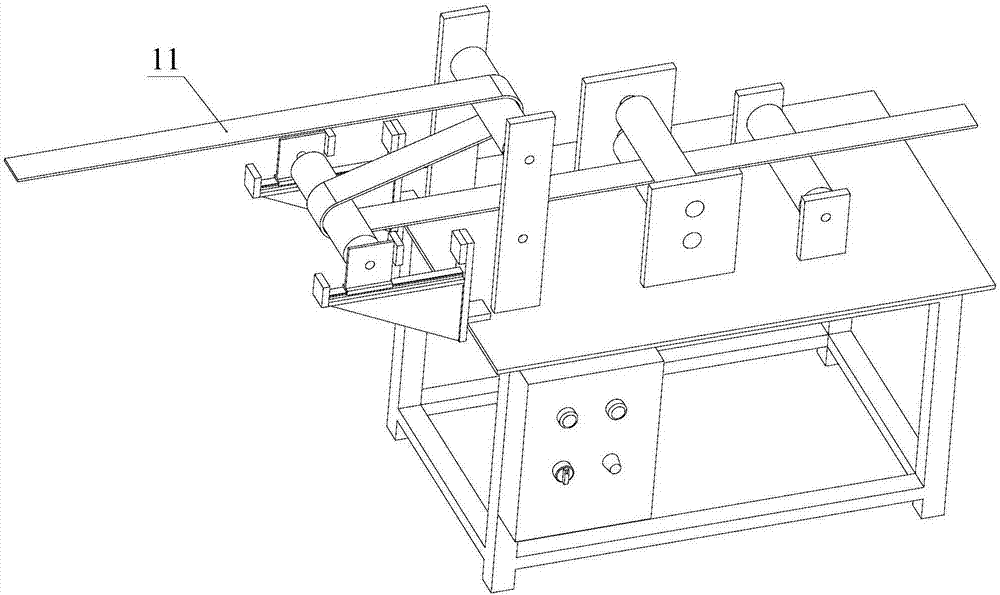

[0029] Below in conjunction with each accompanying drawing, the present invention is described in detail.

[0030] Such as figure 1 Shown, a buffer device for optical cable production, comprising:

[0031] Rack 1, with slide rails 6 on the rack 1;

[0032] The slider 4 is movably matched with the slide rail 6, and the slider 4 can reciprocate along the slide rail 6;

[0033] The first guide roller 8 and the second guide roller 3 arranged in parallel, the first guide roller 8 is rotatably installed on the frame 1, and the second guide roller 3 is rotatably installed on the slider 4;

[0034] The first magnetic block 7 and the second magnetic block 5, the first magnetic block 7 is installed on the frame 1, the second magnetic block 5 is installed on the slider 4, the first magnetic block 7 and the second magnetic block 5 cooperate with each other, The second guide roller 3 has a tendency to move away from the first guide roller 8 by magnetic force.

[0035] The buffering dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com