Lithium-ion battery negative electrode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem that the high-capacity negative electrode material body cannot stably exert high-capacity performance, etc., to improve cycle stability, avoid mutual agglomeration, The effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

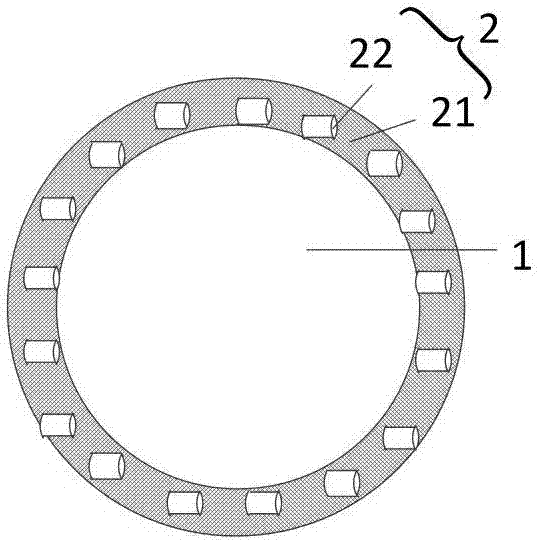

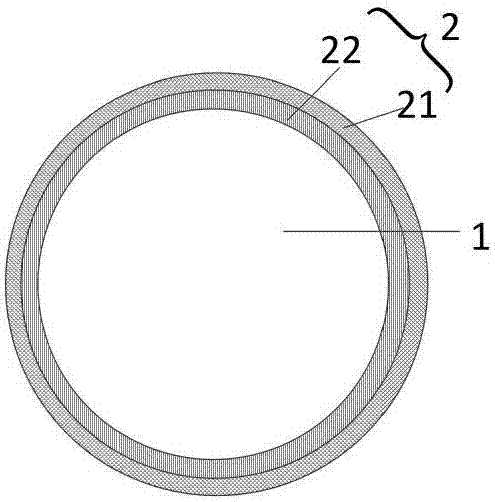

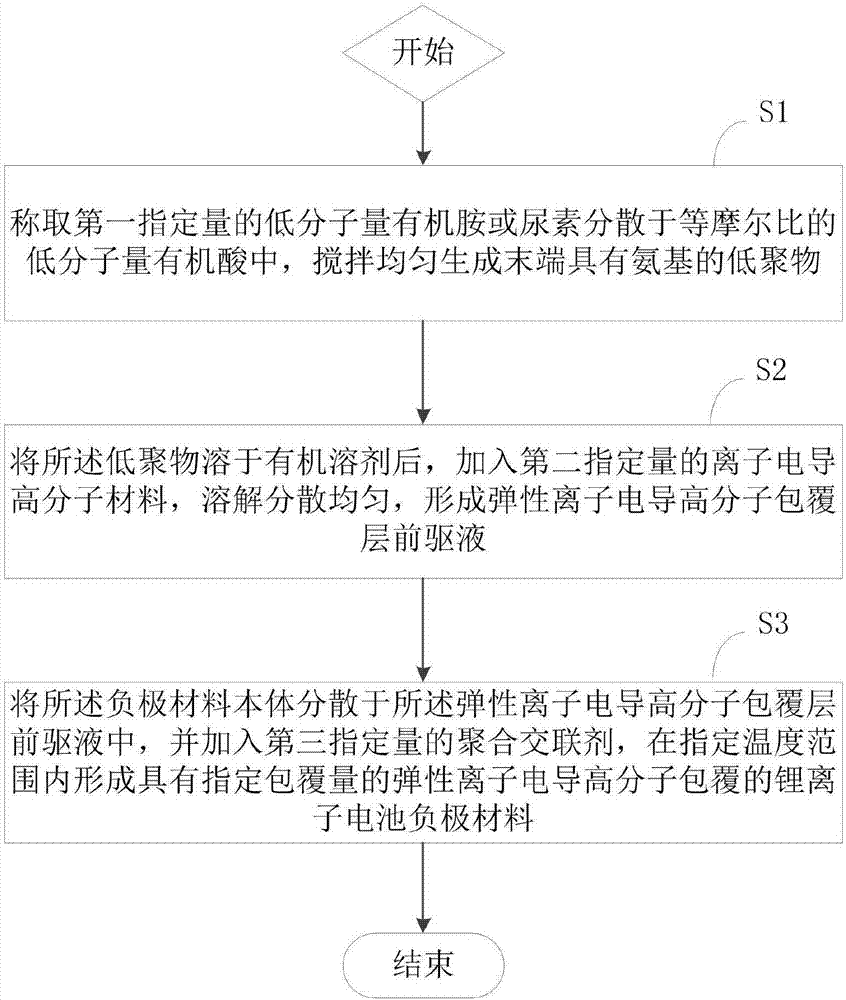

[0037] refer to image 3 , the embodiment of the present invention also provides a preparation method of lithium ion battery negative electrode material, comprising:

[0038] S1: Weigh the first specified amount of low-molecular-weight organic amine or urea and disperse it in the low-molecular-weight organic acid in an equimolar ratio, and stir evenly to form oligomers with amino groups at the end.

[0039] Low molecular weight in this step means that the molecular weight is less than or equal to 1000, so that it can be easily dissolved and dispersed uniformly. Equivalent molar ratio can make the substance react completely. The generation of oligomers with amino groups at the end is conducive to the formation of a large number of hydrogen bonds, so as to increase the elastic properties of polymers, help to absorb the stress generated by the volume expansion of the negative electrode material body 1 during the charge and discharge process, and slow down the volume expansion an...

Embodiment 1

[0058] Mix malonic acid and malonic acid with a mass ratio of 4:6, then add urea in an equimolar ratio to the total mass of malonic acid and malonic acid and p-phenylenediamine accounting for 5% of the mass of urea , stir evenly, and react to form oligomers with amino groups at the end; disperse a specified amount of 0.1um SiO powder in deionized water, and add it to a specified amount of liquid phase pitch after being uniformly dispersed, and then place it in nitrogen at a high temperature of 900°C After carbonization for 5 hours, 4wt% carbon-coated SiO / C was obtained; SiO / C was dispersed in the ethanol-dissolved oligomer liquid with amino groups at the end, and then added in an amount of 85% of the amount of oligomers with amino groups at the end. The cross-linking agent adipic acid and polyethylene glycol with 2% mass of SiO powder form an elastic ion-conductive composite polymer coating layer at 200°C, wherein the polymer coating amount is 2%, and the single particle size i...

Embodiment 2

[0061] Mix malonic acid and malonic acid with a mass ratio of 5:5, then add diethylenetriamine in an equimolar ratio to the total mass of malonic acid and malonic acid and account for 10% of the mass of diethylenetriamine % of p-phenylenediamine, stir evenly, and react to form oligomers with amino groups at the end; disperse a specified amount of 1um SiO powder in deionized water, and add it to a specified amount of liquid phase pitch after uniform dispersion, and then place in High-temperature carbonization treatment at 1500°C in nitrogen for 4 hours to obtain 6wt% carbon-coated SiO / C; SiO / C was dispersed in ethanol-dissolved oligomer liquid with amino groups at the end, and then added in an amount equal to the mass of oligomers with amino groups at the end 100% of the polymeric cross-linking agent glutaric acid and 5% of the polyethylene glycol of the SiO powder mass form an elastic ion-conductive composite polymer coating layer at 300 ° C, wherein the polymer coating amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com