Lithium ion battery positive electrode active material and preparation method thereof

A positive electrode active material and lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as electrolyte side reactions, capacity degradation, distortion, etc., to slow down impedance growth, suppress side reactions, and suppress growth thick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

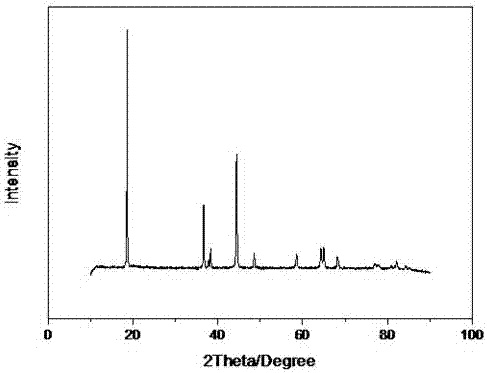

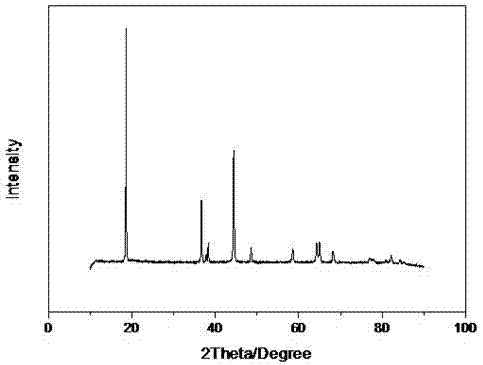

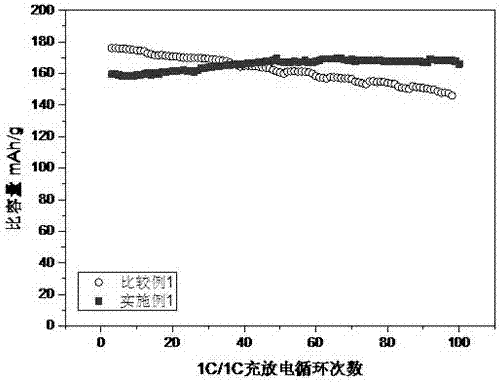

Embodiment 1

[0025] Put 20L of 0.2-2mol / L dilute ammonia water into the 100L reactor as the bottom liquid, perform mechanical stirring at a speed of 400 rpm, and pass in nitrogen for atmosphere protection. Dissolve 288g of molybdenum oxide in 5L of 7mol / L excess ammonia solution, prepare 0.4mol / L ammonium orthomolybdate solution as the second complexing agent solution, and put it into storage tank A. Provide 5L of 5-10mol / L ammonia solution as the first complexing agent solution, and put it into storage tank B. The liquid storage tank A is added to the liquid storage tank B at a flow rate of 0.25L / h, and the liquid storage tank B is kept stirring at 150 rpm and continuously added to the reaction kettle at a flow rate of 0.5L / h. At this time, the tank B flows out The solution is a gradient concentration solution of Mo element. From 0h to 20h in the effluent of tank B, the Mo concentration will gradually increase from 0mol / L to 0.4mol / L. In addition, 2mol / L Ni was continuously added to the...

Embodiment 2

[0029] Put 25L of 0.2-2mol / L dilute ammonia water into the 100L reactor as the bottom liquid, perform mechanical stirring at a speed of 600 rpm, and pass in argon gas for atmosphere protection. Dissolve 230g of molybdenum oxide in 5L of 5mol / L excess ammonia solution, prepare 0.32mol / L ammonium orthomolybdate solution as the second complexing agent solution, and put it into storage tank A. Provide 5L of 5-10mol / L ammonia solution as the first complexing agent solution, and put it into storage tank B. The liquid storage tank A is added to the liquid storage tank B at a flow rate of 0.25L / h, and the liquid storage tank B is kept stirring at 50 rpm and continuously added to the reaction kettle at a flow rate of 0.5L / h. At this time, the tank B flows out The solution is a gradient concentration solution of Mo element. From 0h to 20h in the effluent of tank B, the Mo concentration will gradually increase from 0mol / L to 0.32mol / L. In addition, 2mol / L Ni was continuously added to t...

Embodiment 3

[0033] Put 10L of 0.2-2mol / L dilute ammonia water into the 100L reactor as the bottom liquid, perform mechanical stirring at a speed of 500 rpm, and pass in nitrogen for atmosphere protection. Dissolve 230g of molybdenum oxide in 5L of 6mol / L excess ammonia solution, prepare 0.32mol / L ammonium orthomolybdate solution as the second complexing agent solution, and put it into storage tank A. Provide 5L of 5-10mol / L ammonia solution as the first complexing agent solution, and put it into storage tank B. The liquid storage tank A is added to the liquid storage tank B at a flow rate of 0.25L / h, and the liquid storage tank B is kept stirring at 100 rpm and continuously added to the reaction kettle at a flow rate of 0.5L / h. At this time, the tank B flows out The solution is a gradient concentration solution of Mo element. From 0h to 20h in the effluent of tank B, the Mo concentration will gradually increase from 0mol / L to 0.32mol / L. In addition, 2mol / L Ni was continuously added to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com