Aluminum alloy anode material for aluminum-air battery and preparation method

An anode material, air battery technology, applied in battery electrodes, negative electrodes, active material electrodes, etc., to achieve the effects of high energy density, high anode efficiency, and smooth morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

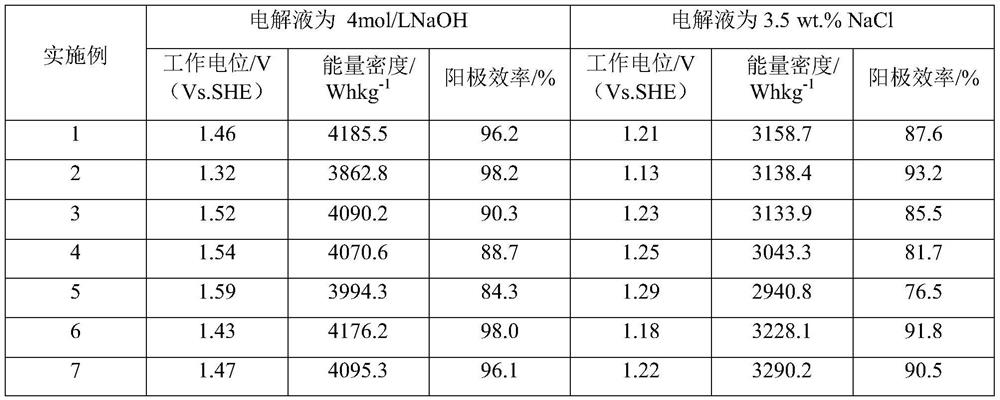

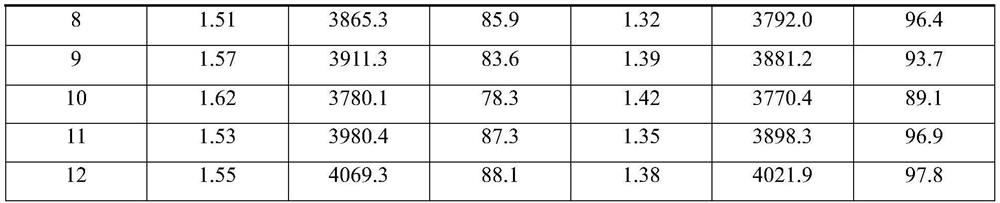

Examples

preparation example Construction

[0025] The present invention also provides a method for preparing the above-mentioned aluminum alloy anode material. The aluminum alloy anode material is obtained through smelting, degassing, slag removal, casting, homogenization, rolling, heat treatment and post-treatment processes, specifically , which includes the following steps:

[0026] Melting: Dosing according to the alloy composition, adding industrial pure aluminum to the medium frequency induction furnace, heating to 740-780°C to melt, then controlling the temperature at 720-740°C, adding aluminum scandium-zirconium master alloy and aluminum manganese to the melt For intermediate alloys, after 30-60 minutes of heat preservation, electromagnetically stir the melt for 10-30 minutes; then control the temperature of the above-mentioned melt at 700-720°C, and add low-melting point alloy elements (Mg, Sn, Ga) in sequence, low-melting point alloys The elements are pressed into the melt with graphite rods in order of meltin...

Embodiment 1

[0035] This embodiment provides an aluminum alloy anode material for an aluminum-air battery. The composition is: 0.5% Mg, 0.15% Sn, 0.2% Mn, 0.2% Sc, 0.1% Zr, and the balance is Al.

[0036] Its specific preparation method:

[0037] (1) Dosing according to the alloy composition, add industrial pure aluminum to the medium frequency induction furnace, heat to 760°C to melt, then control the temperature at 740°C, add Al2ScZr master alloy and Al10Mn master alloy to the melt, keep it for 40min , electromagnetically stir the melt for 15 minutes; then control the temperature of the above melt at 720°C, add pure industrial pure magnesium and industrial pure tin in turn, keep warm for 10 minutes, and then electromagnetically stir the melt for 10 minutes;

[0038] (2) At 740°C, the above-mentioned melt is introduced into a static furnace, and a mixture of argon and hexachloroethane powder is introduced into the static furnace (the concentration of hexachloroethane is 40 to 60 g / m 3 ) ...

Embodiment 2

[0045] The difference between this example and Example 1 lies in the composition of the aluminum alloy anode material. This example provides an aluminum alloy anode material for an aluminum-air battery. The composition is: 0.1% Mg, 0.005% Sn, 0.05% Mn, 0.05% Sc, 0.025% Zr, the balance is Al.

[0046] The preparation method of this embodiment is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com