Rare earth-free aluminum alloy and preparation method and application thereof

An aluminum alloy, rare-earth-free technology, applied in the field of rare-earth-free aluminum alloys and its preparation, can solve the problems of reduced discharge voltage and energy density, reduced electrochemical activity, and high production costs, and achieves improved discharge voltage and energy density, electrochemical The effect of improving activity and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a preparation method for the rare earth-free aluminum alloy described in the above technical solution, comprising the following steps:

[0031] According to the mass ratio of metal elements in the above-mentioned rare earth-free aluminum alloy, Bi source, In source, Mg source and Al source are mixed and melted to obtain a melt;

[0032] After casting the molten liquid, rolling and annealing are performed in sequence to obtain the rare earth-free aluminum alloy.

[0033] In the present invention, unless otherwise specified, all raw materials are commercially available products well known to those skilled in the art.

[0034] The present invention mixes and melts Bi source, In source, Mg source and Al source according to the mass ratio of metal elements in the above-mentioned rare earth-free aluminum alloy to obtain molten liquid.

[0035] In the present invention, the Al source is preferably aluminum metal, the Bi source is preferably...

Embodiment 1

[0048] Melt metal aluminum at 760°C for 10 minutes to obtain molten aluminum;

[0049] Add metal bismuth, metal indium and metal magnesium wrapped in aluminum foil into the molten aluminum, and carry out the second melting under stirring. The melting temperature is 760°C and the time is 10 minutes to obtain the molten liquid;

[0050] Preheat the mold to 240°C, pour the molten liquid into the mold and cast it into the mold. The casting time is 5 minutes to obtain a 1cm thick molded plate;

[0051] The formed plate is cold-rolled, and the thickness is reduced to 0.1 cm in each pass, and a rolled plate with a thickness of 0.2 cm is obtained after rolling 8 times;

[0052] The rolled sheet was annealed at 350°C for 6 hours to obtain a rare earth-free aluminum alloy.

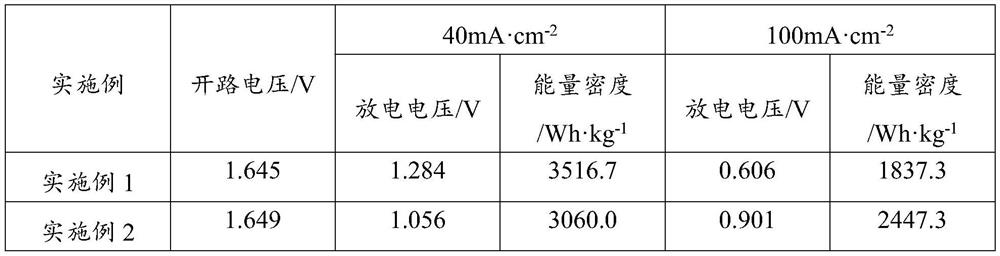

Embodiment 2~5 and comparative example 1~3

[0054] Aluminum alloys were prepared according to the method of Example 1, wherein the components of each example and comparative example are shown in Table 1.

[0055] Table 1 The composition of the aluminum alloys prepared in Examples 1-5 and Comparative Examples 1-3

[0056] Bi / wt% In / wt% Mg / wt% Al / wt% Example 1 0.2 0.075 0.5 99.225% Example 2 0.4 0.075 0.5 99.025% Example 3 0.6 0.075 0.5 98.825% Example 4 0.8 0.075 0.5 98.625% Example 5 1.0 0.075 0.5 98.425% Comparative example 1 0 0 0 100% Comparative example 2 0 0.075 0.5 99.425% Comparative example 3 0 0.5 0.5 99.0%

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com