Magnesium alloy for magnesium secondary battery negative electrode material and preparation method of magnesium alloy

A negative electrode material, magnesium alloy technology, applied in the field of materials, can solve the problems of cycle performance and corrosion resistance, and achieve the effects of low cost, improved corrosion resistance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

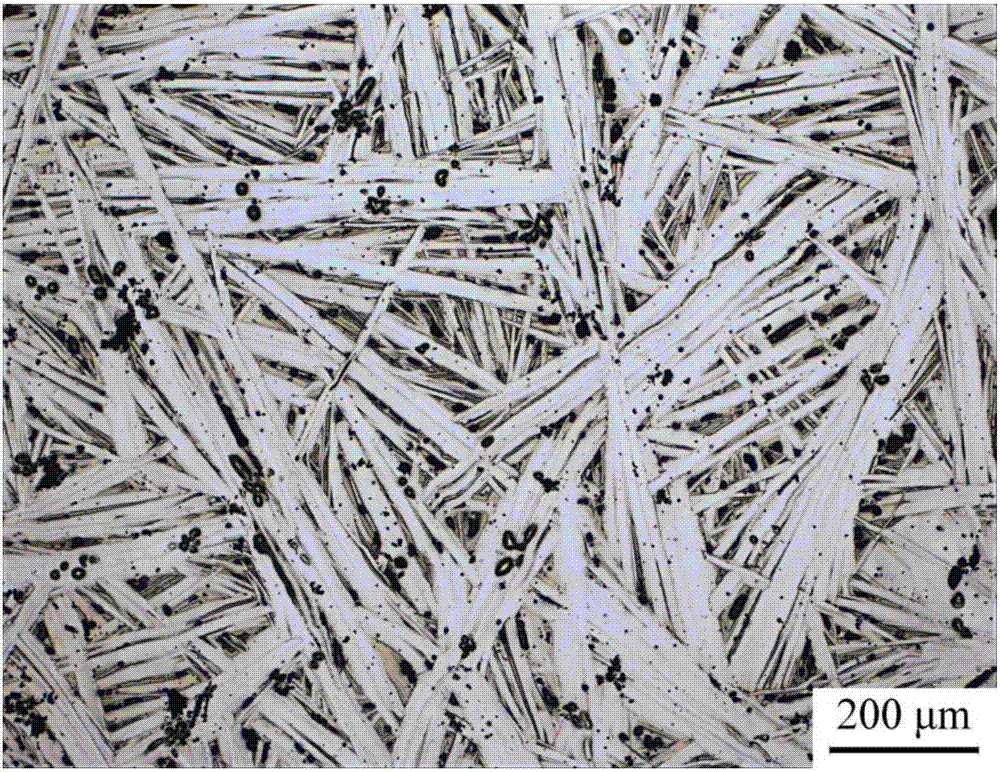

Image

Examples

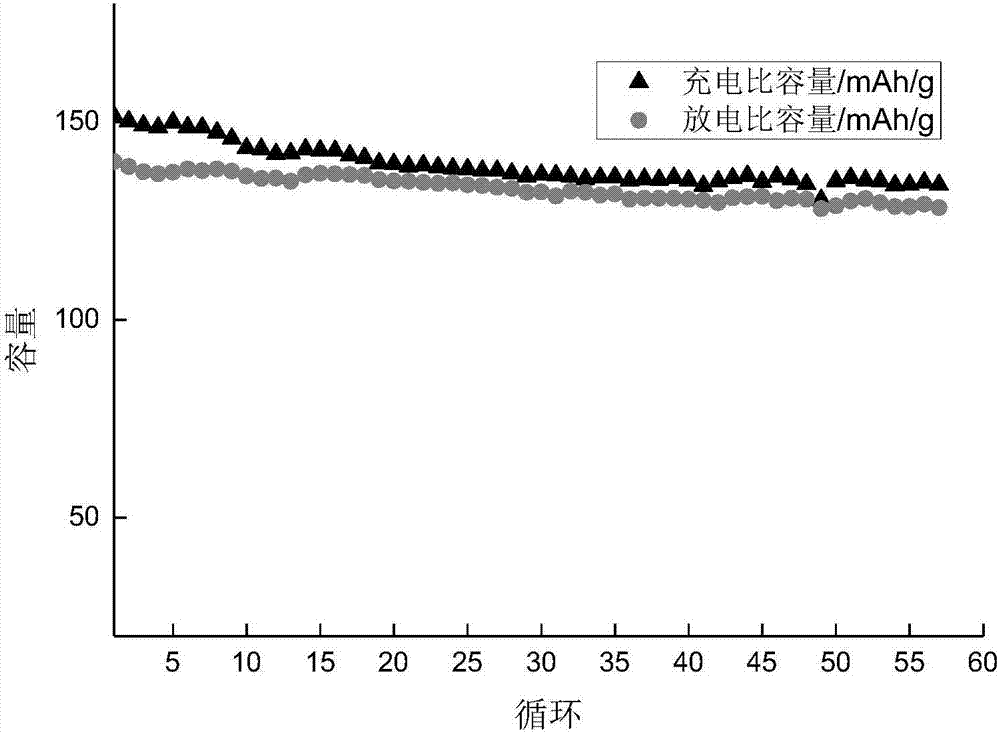

Embodiment 1

[0022] The Mg-6%Y-3%Zn magnesium alloy is processed into a hollow cylinder and a corresponding solid round rod by wire cutting. The inner diameter of the hollow cylinder is 6mm, the outer diameter is 10mm, and the height is 10mm. The diameter of the solid round rod is equal to the inner diameter of the hollow cylinder. , with a height of 4mm; use sandpaper to polish the surface of the Mg-6%Y-3%Zn alloy to remove the oxide layer;

[0023] Put the arsenic element into the above-mentioned Mg-6%Y-3%Zn alloy hollow cylinder, seal the two ends of the hollow cylinder with solid round rods, then wrap the whole hollow cylinder with tantalum film, and put the wrapped alloy into graphite Put the sealed graphite tube into the middle of a circular hole in the middle of a cubic pyrophyllite block, and finally seal the top and bottom of the graphite tube with two graphite sheets with the same diameter as the outer diameter of the graphite tube. Set two conductive steel rings at the end;

[...

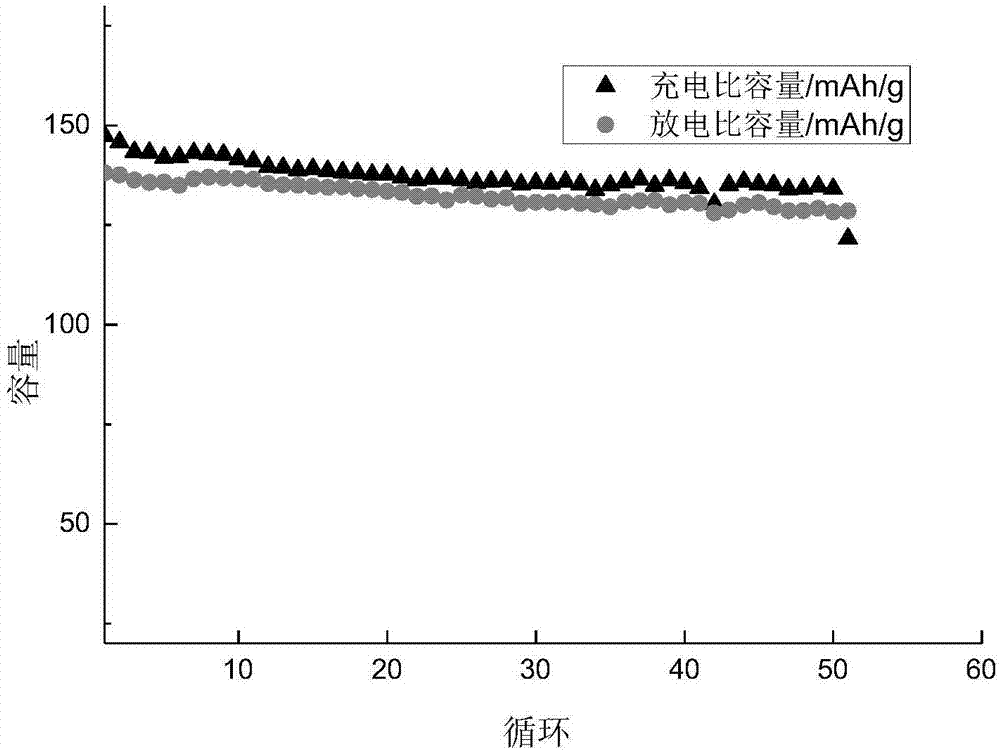

Embodiment 2

[0027] The Mg-6%Y-9%Zn magnesium alloy is processed into a hollow cylinder and a corresponding solid round rod by wire cutting. The inner diameter of the hollow cylinder is 7mm, the outer diameter is 11mm, and the height is 13mm. The diameter of the solid round rod is equal to the inner diameter of the hollow cylinder. , with a height of 5mm; use sandpaper to polish the surface of the Mg-6%Y-9%Zn alloy to remove the oxide layer;

[0028] Put the arsenic element into the above-mentioned Mg-6%Y-9%Zn alloy hollow cylinder, seal the two ends of the hollow cylinder with solid round rods, then wrap the whole hollow cylinder with tantalum film, and put the wrapped alloy into graphite Put the sealed graphite tube into the middle of a circular hole in the middle of a cubic pyrophyllite block, and finally seal the top and bottom of the graphite tube with two graphite sheets with the same diameter as the outer diameter of the graphite tube. Set two conductive steel rings at the end...

Embodiment 3

[0032] The Mg-2%Er-1%Zn magnesium alloy is processed into a hollow cylinder and a corresponding solid round rod by wire cutting. The inner diameter of the hollow cylinder is 8mm, the outer diameter is 12mm, and the height is 16mm. The diameter of the solid round rod is equal to the inner diameter of the hollow cylinder. , with a height of 7mm; use sandpaper to polish the surface of the Mg-2%Er-1%Zn alloy to remove the oxide layer;

[0033] Put the arsenic element into the above-mentioned Mg-2%Er-1%Zn alloy hollow cylinder, seal the two ends of the hollow cylinder with solid round rods, then wrap the whole hollow cylinder with tantalum film, and put the wrapped alloy into graphite Put the sealed graphite tube into the middle of a circular hole in the middle of a cubic pyrophyllite block, and finally seal the top and bottom of the graphite tube with two graphite sheets with the same diameter as the outer diameter of the graphite tube. Set two conductive steel rings at the end; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com