Winding device for ultrathin metal lithium strip

A winding device and ultra-thin metal technology, applied in the field of winding devices, can solve problems such as uneven force, stretching deformation, easy stretching deformation, etc., to avoid stretching deformation or breakage, increase strength, and reduce stress uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

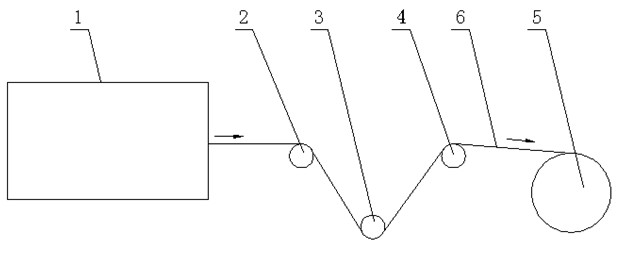

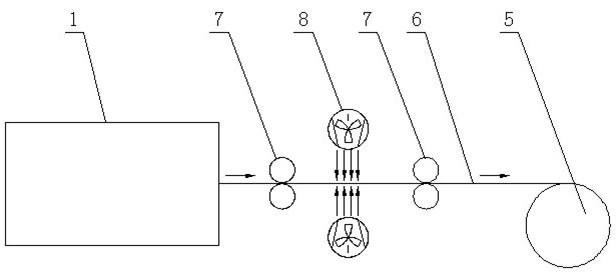

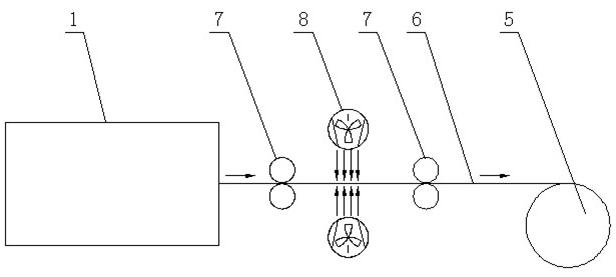

[0014] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0015] figure 2 It is a schematic structural view of the ultra-thin metal lithium strip winding device of the present invention, as shown in the figure, the ultra-thin metal lithium strip winding device of the present invention includes a winding machine 5 and two pairs of pinch rollers 7, and two pairs of pinch rollers The rollers 7 are arranged side by side, and one pair of pinch rollers 7 is connected to the die opening of the metal lithium strip extrusion machine 1, and the other pair of pinch rollers 7 is connected to the winding machine 5; the metal lithium strip 6 is connected to the metal lithium strip extrusion machine 1 After the die mouth flows out, it is led to the winder 5 by two pairs of pinch rollers 7 for winding, and the tension of the metal lithium strip 6 is controlled by the pinch rollers 7, so that the metal lithium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com