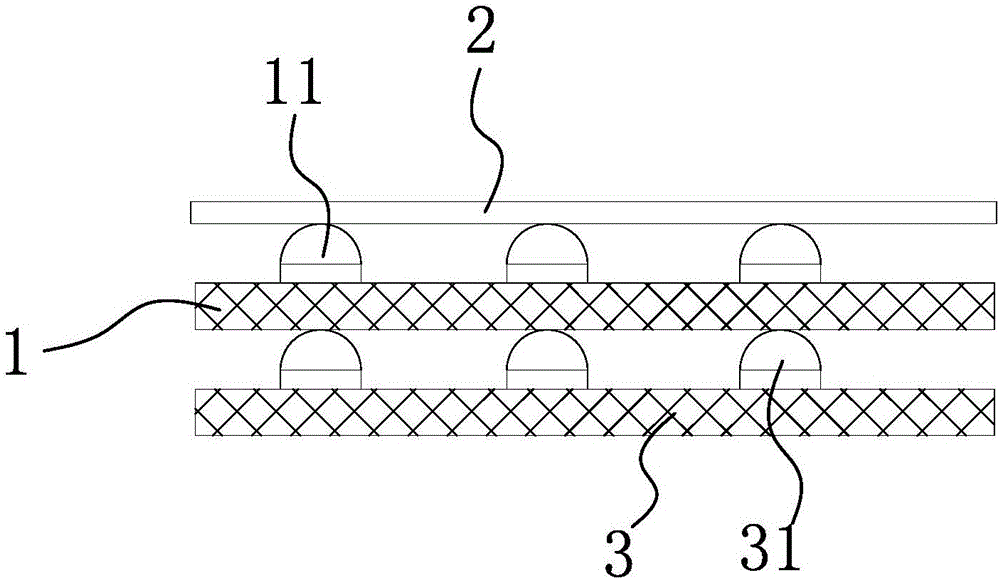

Three-layer knitted composite fabric and production technology thereof

A composite fabric and production process technology, applied in the field of clothing materials, can solve the problems of difficult shape and size of cut pieces, insufficient windproof performance and high porosity, achieve a balance between comfort and shape retention, improve dry washing performance, and improve shape retention. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

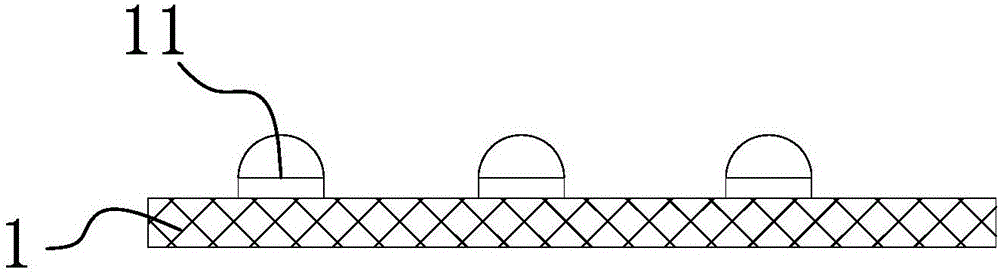

Embodiment 1

[0112] In above-mentioned A step, select weft-knitted tweed fabric and its fabric square gram weight 220 grams / square meter, weft-knitted tweed fabric comprises following composition: polyester staple fiber 49%, acrylic fiber 47% and wool 4%; Raw fabric The positive Martindale friction pilling performance is only 2-2.5. Basically, it cannot be directly made into outerwear fabric. But its appearance color and fabric style are very good, because it contains wool and acrylic fiber material, we use it to play the role of fabric decoration and high-end texture effect in the three-layer composite system.

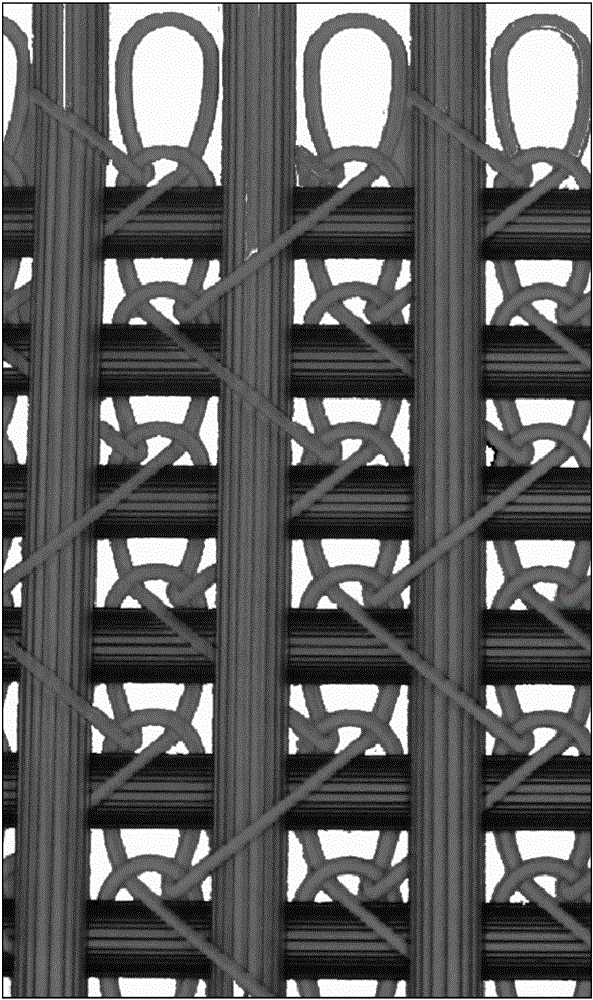

[0113] Select the W5110-04D warp-interleaved and weft-inserted warp-knitted fabric 1 with a square gram weight of 120 grams / square meter; Further, the weaving process of the warp-inserted and weft-inserted warp-knitted fabric 1 of the present embodiment is as follows:

[0114] In the above-mentioned step a1, the warp knitting and weft insertion warp knitting machine is a Karl Ma...

Embodiment 2

[0136] The structure and principle of this embodiment are basically the same as those of Embodiment 1, so they will not be repeated here. The difference lies in:

[0137] In the above-mentioned step A, select a weft-knitted wool fabric with a square gram weight of 130 grams per square meter. The weft-knitted wool fabric includes the following ingredients: 5% cashmere, 75% wool and 20% PTT; Martindale on the front of the original fabric The friction and pilling performance is only 2.5-3 grades. Basically, it cannot be directly made into outerwear fabric. But its appearance color and fabric style are very good, because it is a material with high hair content, we use it in the three-layer composite system to play the role of fabric decoration and high-end texture effect.

[0138] Select the W5145-05D warp-interleaved and weft-inserted warp-knitted fabric 1 with a square gram weight of 57 grams / square meter; The weaving process of the warp-lined and weft-lined warp-knitted fabri...

Embodiment 3

[0160] The structure and principle of this embodiment are basically the same as those of Embodiment 1, so they will not be repeated here. The difference lies in:

[0161] In the above step A, select the knitted modal spandex elastic fabric and its square gram weight is 200 g / m2, the knitted modal spandex elastic fabric includes the following components: 94% modal and 6% spandex; Martindale friction on the front of the original fabric The pilling performance is only 3.5. Because the elasticity is too large, it is basically impossible to directly make it into a dress fabric. But its appearance, color and fabric style are very good. Originally, it was mainly used for tight underwear or special casual clothing. We use it in the three-layer composite system for fabric decoration and high-end texture effect. It can be used to make jackets or Simple suit.

[0162] Selecting the W6145-08D warp interlining and weft interlining warp knitted fabric 1 with a square gram weight of 57 gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com