Electromagnetic heating welding method for thermoplastic pipes

A thermoplastic and electromagnetic induction heating technology, which is applied in the direction of pipeline connection layout, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of high labor costs and pipes that cannot be exposed to the air for a long time, so as to reduce labor costs, The effect of maintaining strength and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

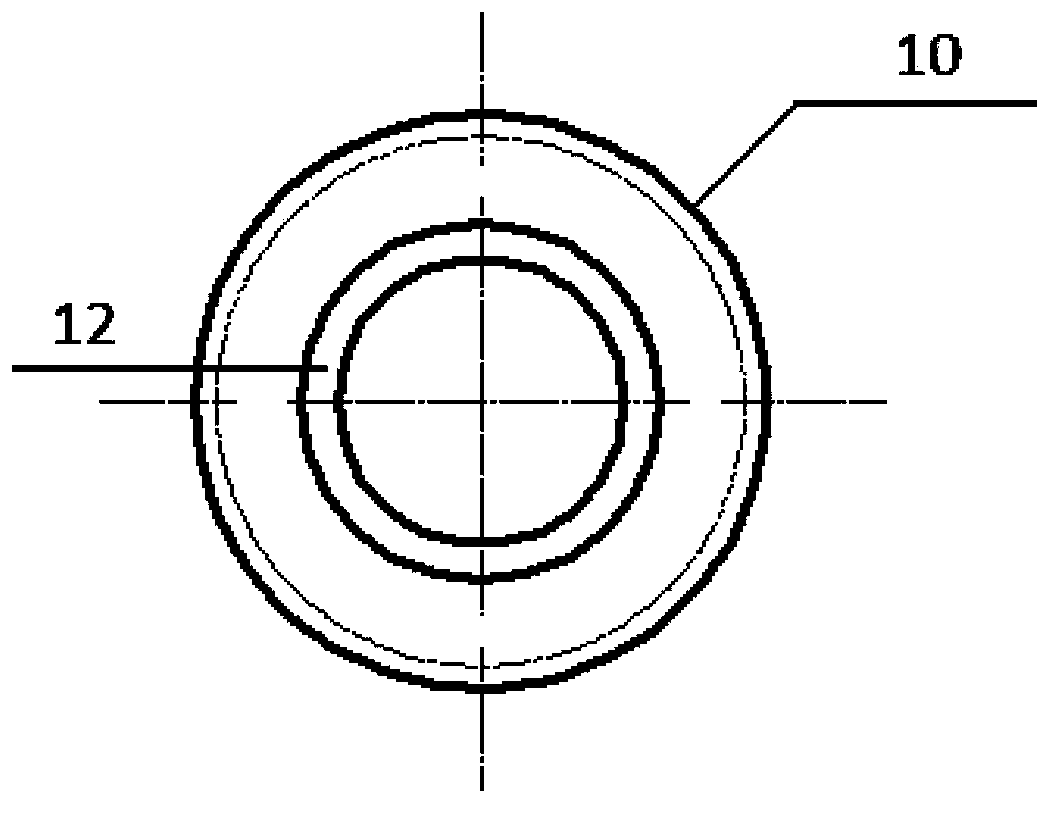

[0025] Such as figure 1 As shown, an annular metal mesh layer 12 is provided on the inner wall of the plastic connector 10, and the metal mesh layer 12 converts electromagnetic energy into heat energy and makes the junction of two thermoplastic pipes thermally fused.

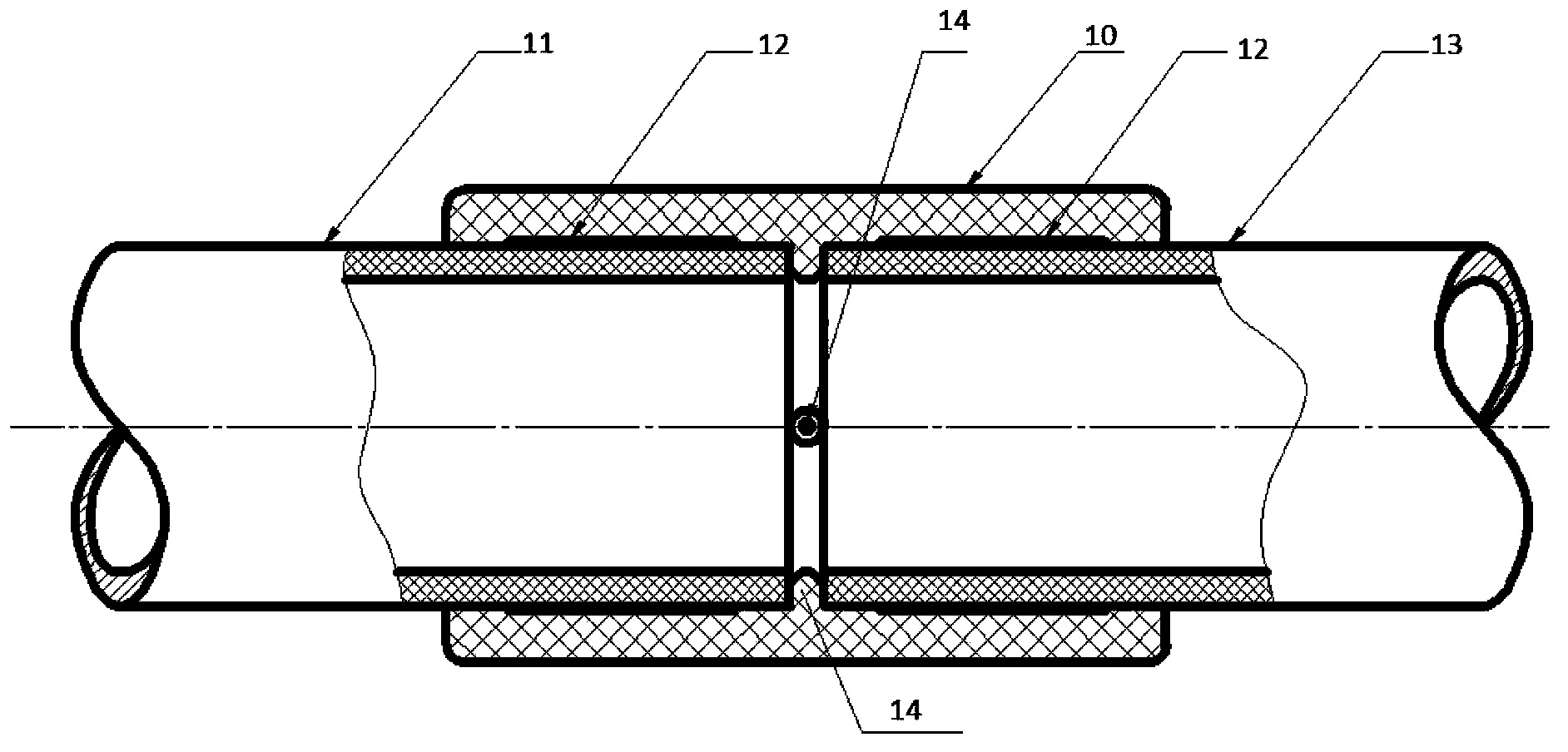

[0026] Such as figure 2 As shown, the two thermoplastic pipes are thermoplastic pipe A11 and thermoplastic pipe B13 respectively, and the thermoplastic pipe B13 and thermoplastic pipe A11 are respectively inserted into the two ends of the plastic connector 10, and the metal mesh layer 12 is fixed on the inner wall of the plastic connector 10 superior.

[0027] The inner wall of the plastic connector 10 is also provided with positioning pins 14 to limit the insertion positions of the thermoplastic pipe B13 and the thermoplastic pipe A11 .

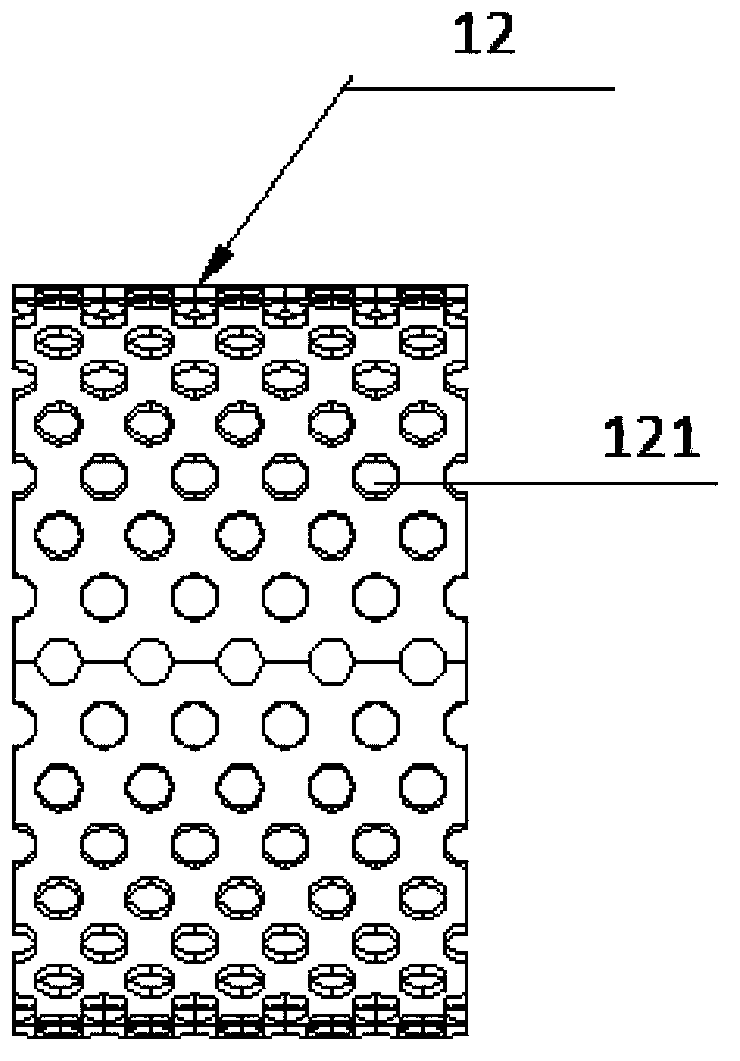

[0028] Such as image 3 As shown, the metal mesh layer 12 is provided with a lot of mesh holes 121, the metal mesh layer 12 generates heat and makes the hot-melted pipe pa...

Embodiment 2

[0031] Such as Figure 4 As shown, the steel-plastic composite pipe 2 includes an outer plastic layer 21 , a first glued layer 22 , a metal layer 23 , a second glued layer 24 and an inner plastic layer 25 from outside to inside. The present invention utilizes the metal layer 23 in the existing structure of the steel-plastic composite pipe 2 to convert electromagnetic energy into thermal energy through the metal layer 22 and make the junction of two steel-plastic composite pipes 2 thermally fused.

[0032] Such as Figure 5 and Figure 6 As shown, two steel-plastic composite pipes 2 need to be connected by a plastic connector 4. The plastic connector 4 is a columnar structure, which includes a cavity 43 and an outer wall 44. The cavity 43 connects the two steel-plastic composite pipes 2 To communicate, the outer wall 44 is connected to the electromagnetic heater.

[0033] One end of the plastic connector 4 is provided with a left annular slot 41, and a steel-plastic composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com