High-strength and large-plasticity multi-stage heterostructure medium-entropy alloy and preparation method thereof

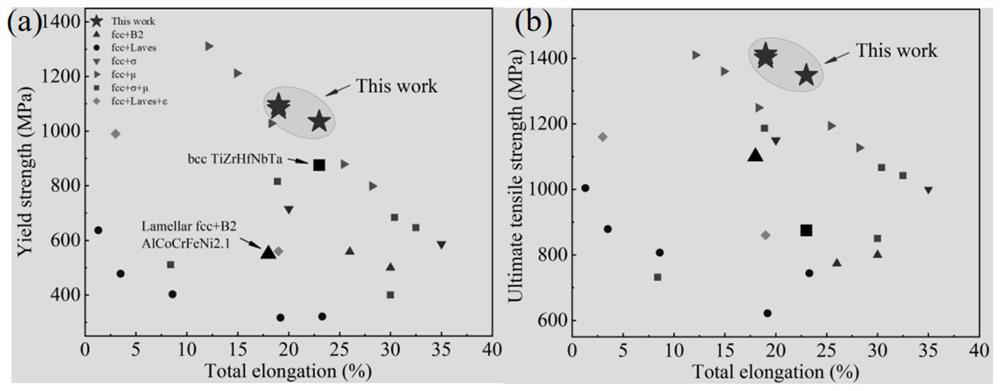

A heterogeneous structure, high plasticity technology, applied in the direction of metal rolling, temperature control, elongation control, etc., can solve the problems of limited yield strength and limited engineering application, and achieve strong plastic deformation ability, improved yield strength and good toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the NiCoCr medium entropy alloy of the above-mentioned dual-phase multi-level heterogeneous structure comprises the following steps:

[0035] Step 1. According to atomic percentage, uniformly mix metal particles of 29-33% Ni, 29-33% Co, 29-33% Cr, 9-12% Al and 1.0-3.0% Ta.

[0036] The weight of raw materials is accurate to 0.01g when weighing, and then the alloy is smelted by vacuum arc melting method.

[0037] During the smelting process, first vacuum to 3Pa, then pass high-purity argon gas and then evacuate, repeat the furnace washing three times to ensure a high-purity vacuum environment, the smelting induction current is 450-550A, the alloy smelting process is accompanied by electromagnetic stirring, and repeated remelting 5 times to ensure the uniformity of the composition, and finally cooled in a water-cooled copper crucible to obtain an ingot;

[0038] Step 2, performing homogenization treatment at a temperature of 1200-1240°C;

[003...

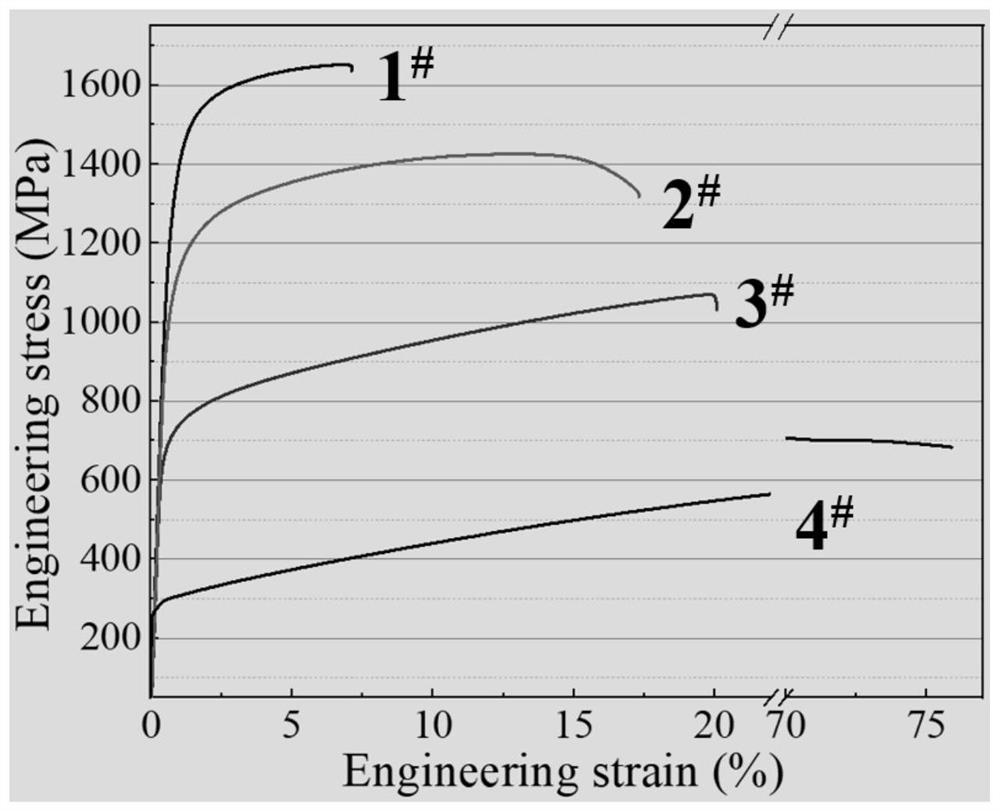

Embodiment 1

[0042] A method for preparing a NiCoCr medium-entropy alloy with a dual-phase multilevel heterogeneous structure, comprising the following steps:

[0043] Step 1. In atomic percentage, uniformly mix metal particles of 29% Ni, 31% Co, 33% Cr, 10% Al and 2% Ta.

[0044]During the smelting process, first vacuum to 3Pa, then pass high-purity argon gas and then evacuate, repeat the furnace washing three times to ensure a high-purity vacuum environment, the smelting induction current is 450A, the alloy smelting process is accompanied by electromagnetic stirring, and repeated remelting 5 times , to ensure the uniformity of the composition, and finally cooled in a water-cooled copper crucible to obtain an ingot;

[0045] Step 2, the alloy ingot is homogenized at 1200°C;

[0046] Step 3, hot rolling at 1150°C, the deformation is controlled at 70%, and the total rolling time is controlled to 10 minutes;

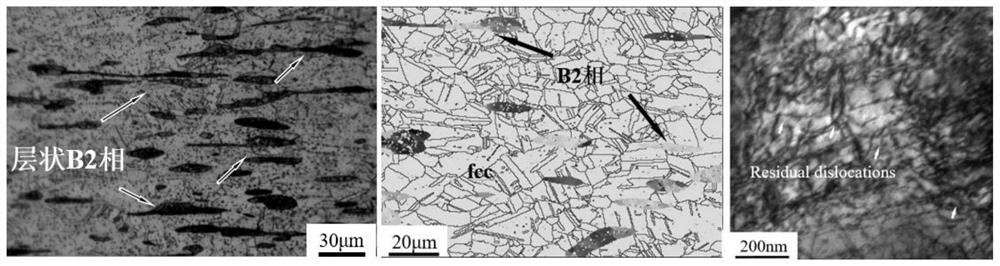

[0047] Step 4. Quenching treatment after the last hot rolling to retain medium-d...

Embodiment 2

[0050] A method for preparing a NiCoCr medium-entropy alloy with a dual-phase multilevel heterogeneous structure, comprising the following steps:

[0051] Step 1. In atomic percentage, uniformly mix metal particles of 31% Ni, 29% Co, 31% Cr, 9% Al and 3.0% Ta.

[0052] During the smelting process, first vacuum to 3Pa, then pass high-purity argon gas and then evacuate, repeat the furnace washing three times to ensure a high-purity vacuum environment, the smelting induction current is 500A, the alloy smelting process is accompanied by electromagnetic stirring, and repeated remelting 5 times , to ensure the uniformity of the composition, and finally cooled in a water-cooled copper crucible to obtain an ingot;

[0053] Step 2, the alloy ingot is homogenized at 1200°C;

[0054] Step 3, hot rolling at 1175°C, the deformation is controlled at 80%, and the total rolling time is controlled to 9 minutes;

[0055] Step 4. Quenching treatment after the last hot rolling to retain medium-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com