Electrodeposition in ionic liquid electrolytes

A technology of ionic liquid and electrodeposition, applied in electrolysis process, electroforming, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

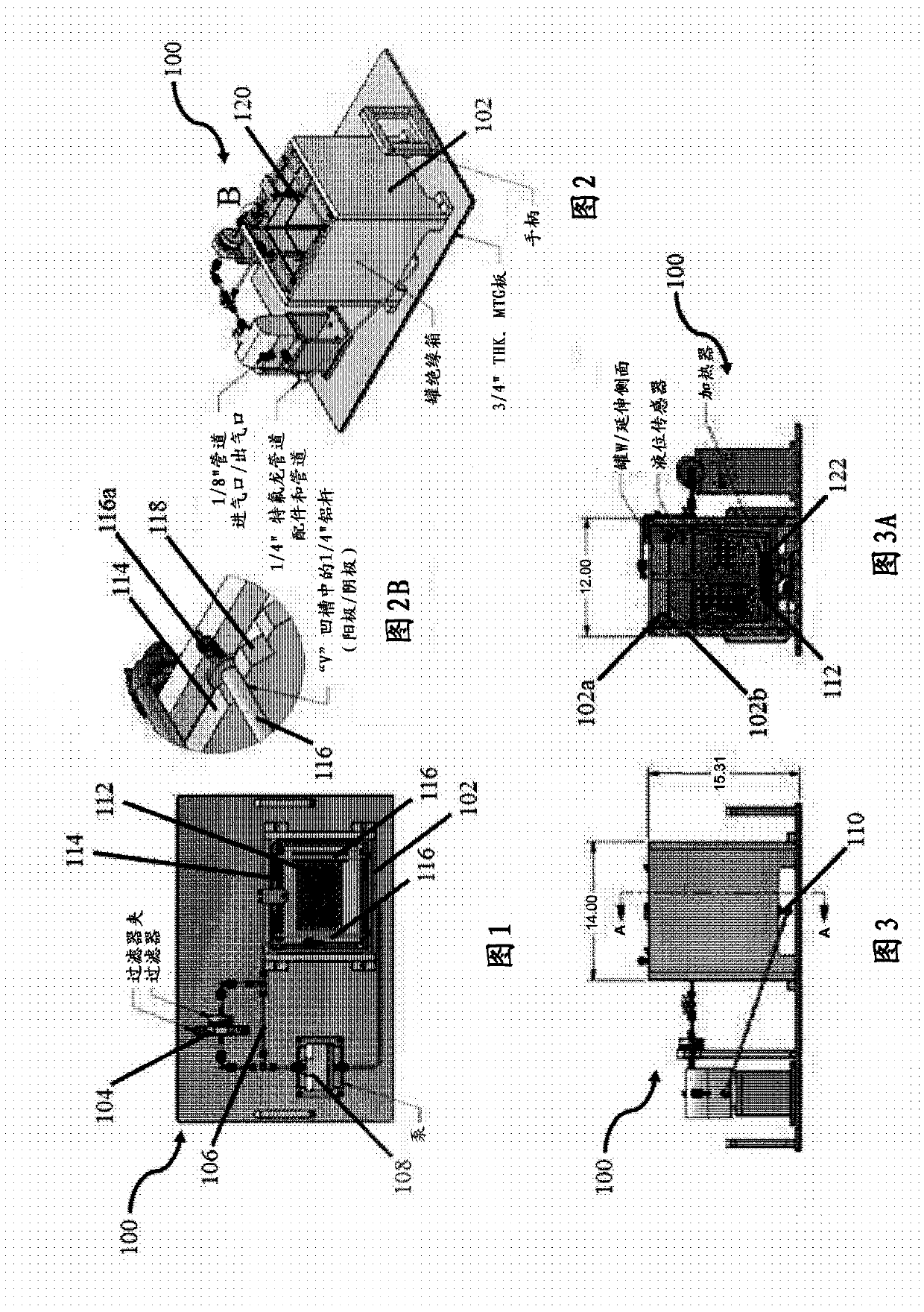

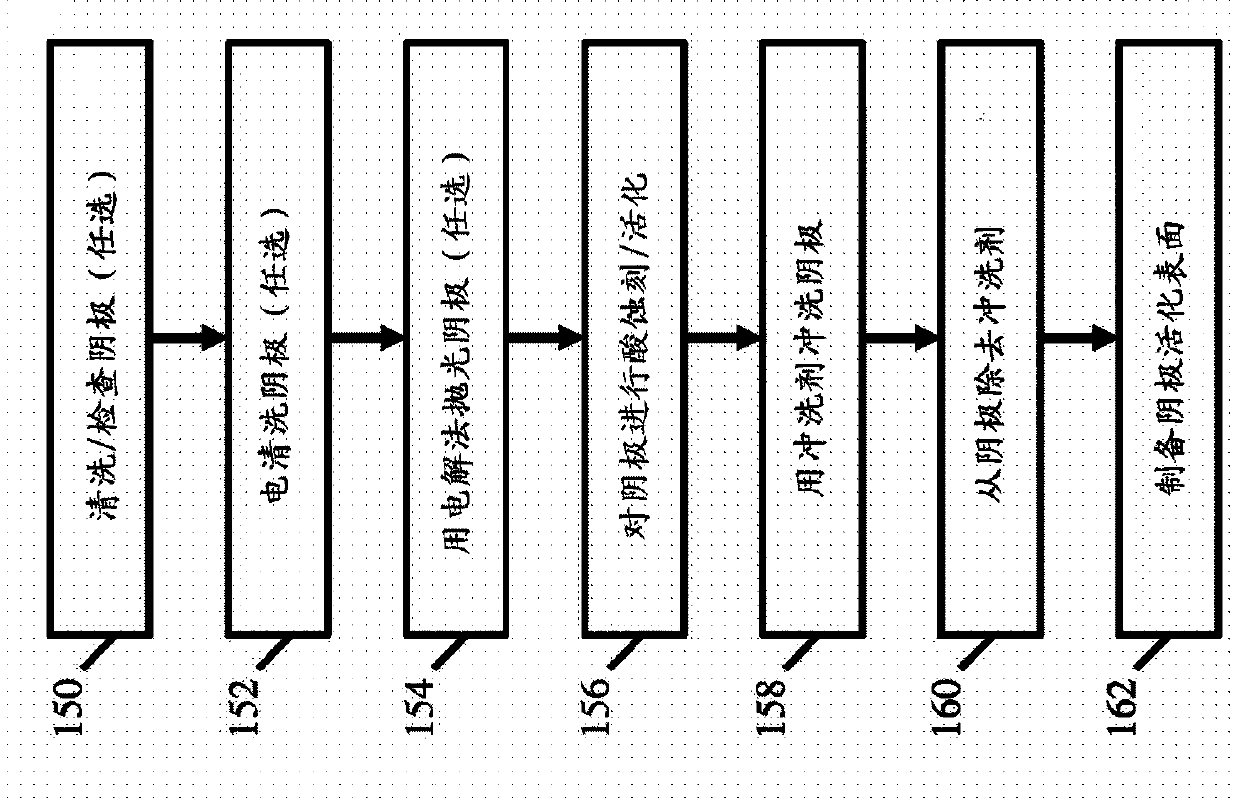

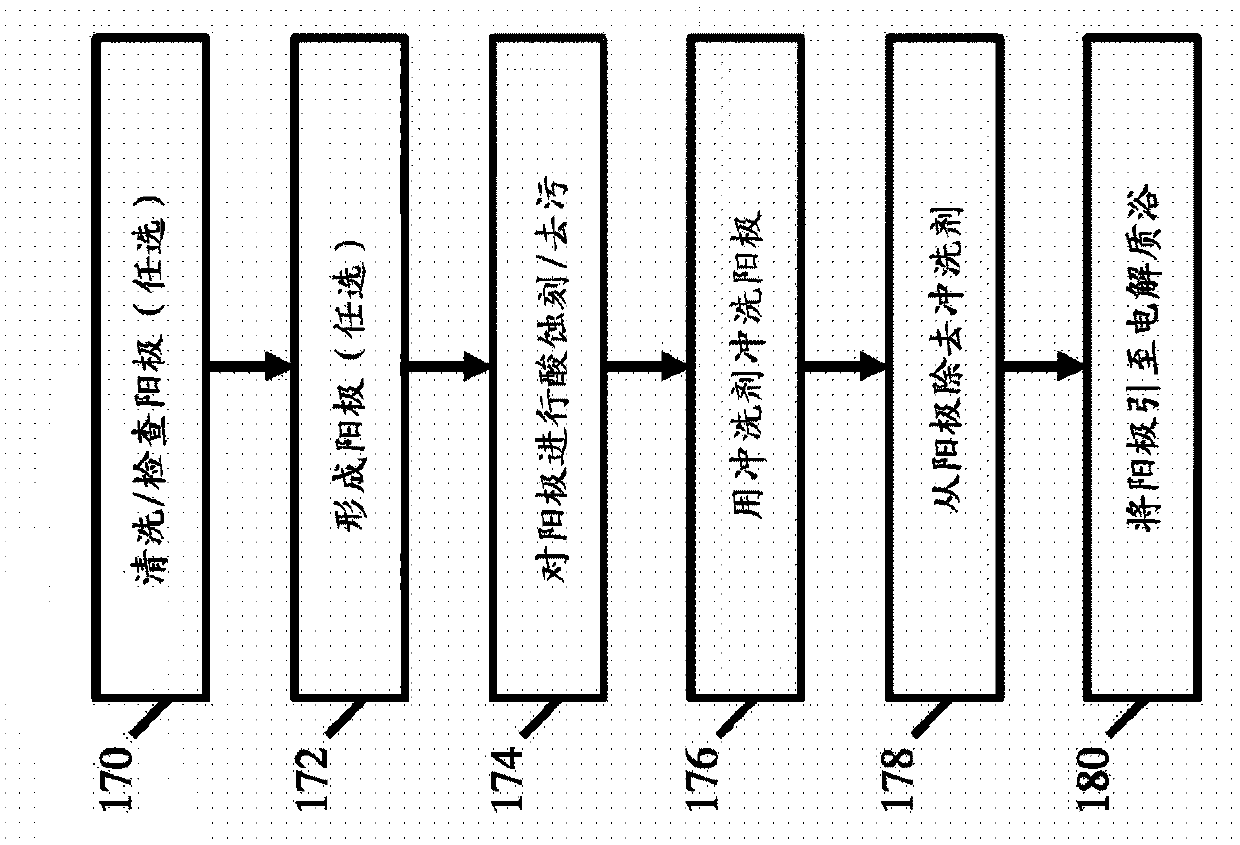

Method used

Image

Examples

Embodiment

[0159] material testing

[0160] Due to the corrosive nature of ionic liquid-based electrolytes, tests were performed to determine the compatibility of materials with the ionic liquids, salts, and additives used in the electrodeposition process disclosed herein. In addition to determining compatibility, the wettability of materials within ionic liquid electrolytes is evaluated to identify materials that are further suitable for use as membranes, separators, and other components within electrodeposition systems that can benefit from wetting by the electrolyte bath. wet. Material compatibility was tested by submerging a known mass sample for each material in a known volume of ionic liquid electrolyte. The samples were immersed in the ionic liquid electrolyte for up to one month at room temperature. After the long-term immersion test, the samples were evaluated for changes in their physical properties including their mass, volume, size, color and stiffness. Materials were ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com