NiCoCr-based medium entropy alloy with excellent strength plasticity matching and preparation method

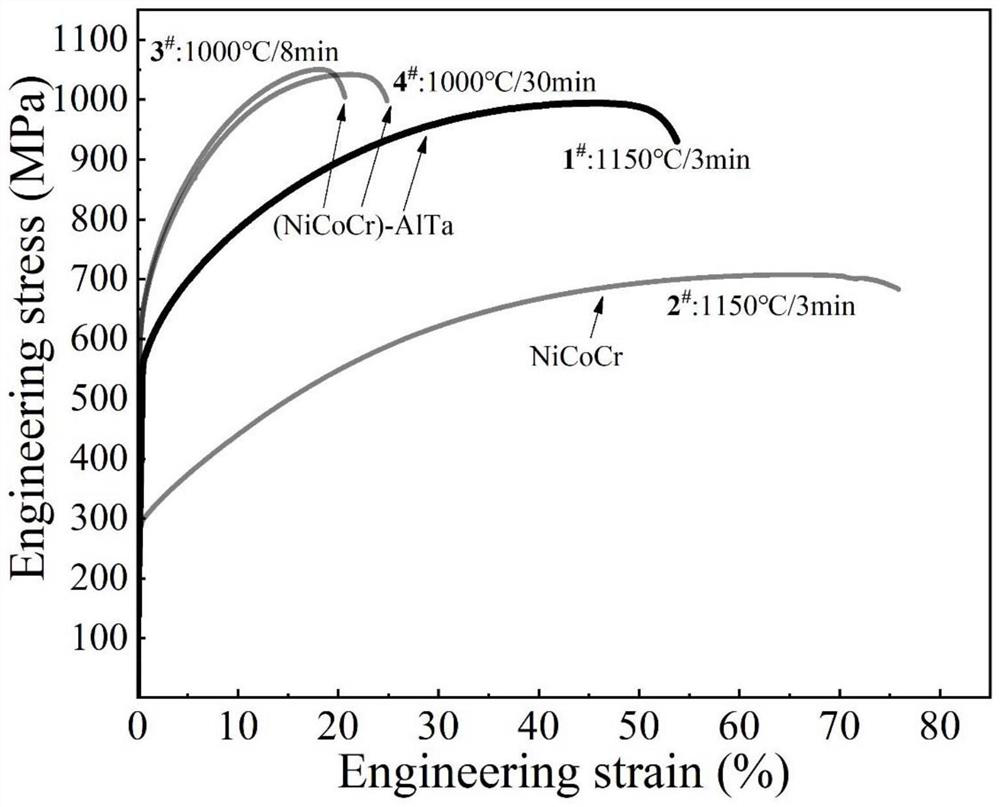

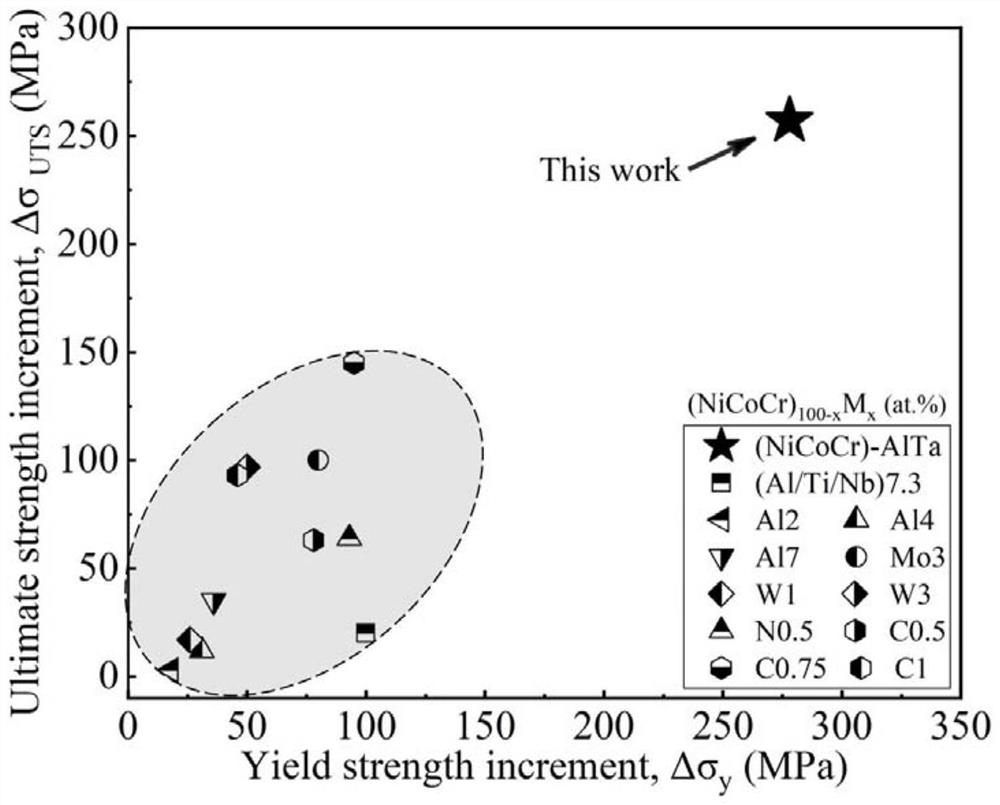

An entropy alloying and strength technology, applied in the field of entropy alloying and preparation in NiCoCr base, can solve problems such as limited yield strength, and achieve the effects of strong plastic deformation ability, excellent strength-plastic matching, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the above-mentioned NiCoCr-AlTa series medium entropy alloy comprises the following steps:

[0030] Step 1. According to atomic percentage, uniformly mix metal particles of 29-33% Ni, 29-33% Co, 29-33% Cr, 4-8% Al and 1.0-3.0% Ta.

[0031] The weight of raw materials is accurate to 0.01g when weighing, and then the alloy is smelted by vacuum arc melting method.

[0032] During the smelting process, first vacuum to 5Pa, then pass high-purity argon gas and then evacuate, repeat the furnace washing three times to ensure a high-purity vacuum environment, the smelting induction current is 400-500A, the alloy smelting process is accompanied by electromagnetic stirring, and repeated remelting 5 times to ensure the uniformity of the composition, and finally cooled in a water-cooled copper crucible to obtain an ingot;

[0033] Step 2, the alloy ingot is homogenized at 1150-1250°C;

[0034] Step 3, cold rolling at room temperature, the amount of deform...

Embodiment 1

[0037] A kind of preparation method of NiCoCr-AlTa system entropy alloy, comprises the following steps:

[0038] Step 1. In atomic percentage, uniformly mix metal particles of 29% Ni, 31% Co, 33% Cr, 4% Al and 3% Ta.

[0039] During the smelting process, first vacuum to 5Pa, then pass high-purity argon gas and then evacuate, repeat the furnace washing three times to ensure a high-purity vacuum environment, the smelting induction current is 400A, the alloy smelting process is accompanied by electromagnetic stirring, and repeated remelting 5 times , to ensure the uniformity of the composition, and finally cooled in a water-cooled copper crucible to obtain an ingot;

[0040] Step 2, the alloy ingot is homogenized at 1150°C;

[0041] Step 3, cold rolling at room temperature, the amount of deformation is controlled at 50%;

[0042] In step 4, a single-phase fcc alloy is obtained after recrystallization annealing at 1100°C.

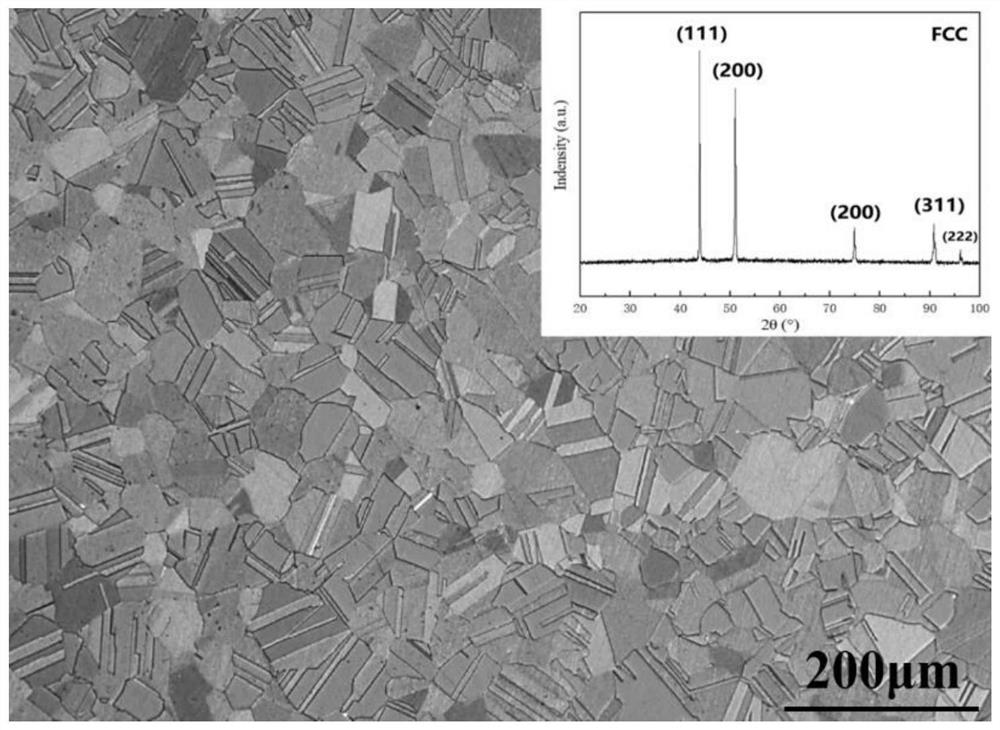

[0043] In the single-phase fcc structure, the equiaxed...

Embodiment 2

[0045] A kind of preparation method of NiCoCr-AlTa system entropy alloy, comprises the following steps:

[0046] Step 1. In atomic percentage, uniformly mix metal particles of 31% Ni, 29% Co, 31% Cr, 7% Al and 2.0% Ta.

[0047]During the smelting process, first vacuum to 5Pa, then pass high-purity argon gas and then evacuate, repeat the furnace washing three times to ensure a high-purity vacuum environment, the smelting induction current is 450A, the alloy smelting process is accompanied by electromagnetic stirring, and repeated remelting 6 times , to ensure the uniformity of the composition, and finally cooled in a water-cooled copper crucible to obtain an ingot;

[0048] Step 2, the alloy ingot is homogenized at 1200°C;

[0049] Step 3, cold rolling at room temperature, the amount of deformation is controlled at 65%;

[0050] Step 4: After recrystallization annealing at 1150° C., a single-phase fcc alloy is obtained.

[0051] In the single-phase fcc structure, the equiaxe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com