High-strength high-ductility TiAl alloy material and preparation method thereof

An alloy material and high plasticity technology, applied in the field of intermetallic compound materials, can solve problems such as affecting the room temperature performance of TiAl alloys, achieve universal applicability and promotion value, improve room temperature brittleness, and prevent alloy pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

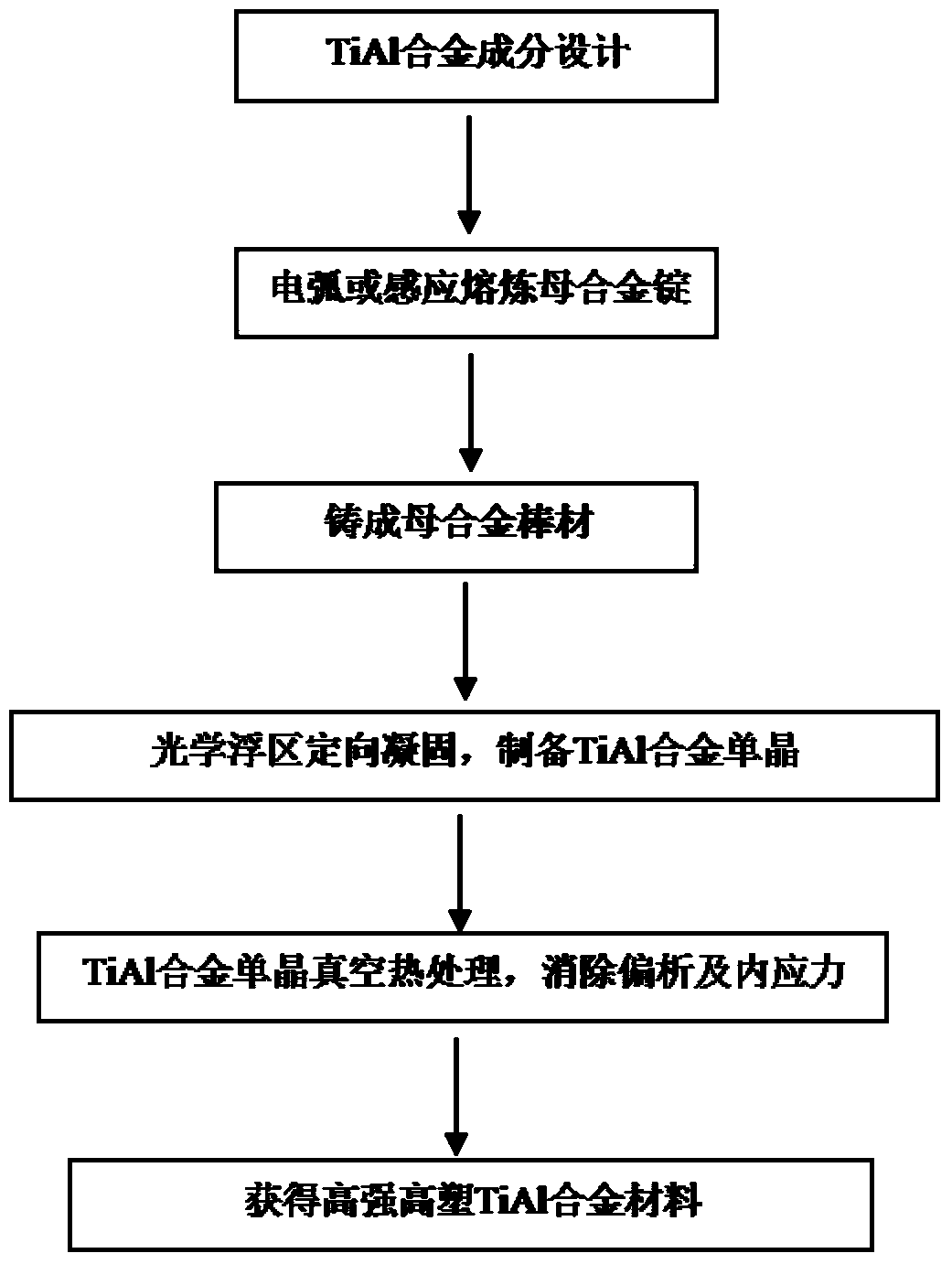

Method used

Image

Examples

Embodiment 1

[0033] (1) Selection of raw materials:

[0034] The alloy composition selected for preparing the master alloy ingot in the present invention is Ti47Al45Nb8 (atomic percentage), and the purity of each metal component is 99.999% for Ti and Al, and 99.95% for Nb.

[0035] (2) Preparation of master alloy ingot:

[0036] Under the protection of high-purity argon gas, master alloy ingots are melted in a water-cooled copper crucible electromagnetic induction suspension melting furnace: after the surface of the metal raw material is mechanically polished to remove the surface oxide skin, the material is prepared according to the designed composition ratio; according to each ingot Put the prepared material into the water-cooled copper crucible in the melting furnace with a weight of about 70g, and vacuumize to 5×10 -3 Pa; fill a certain amount of high-purity argon gas (99.999%) into the furnace, and the pressure range of argon gas is 0.8-1MPa. Multi-pass smelting for 3 to 4 times to ...

Embodiment 2

[0044] Using the same preparation method as in Example 1, the alloy composition is Ti44Al47Nb9 (atomic percentage), the optical floating zone directional solidification process is a relative rotational speed of 20rpm, a heating power of 55%, a growth rate of 2.5mm / h, and a vacuum heat treatment process of 1250°C× 12h+900℃×30min / furnace cooling, the B2 phase is completely eliminated, and the obtained TiAl alloy material has a tensile yield strength of 550MPa at room temperature and a plastic strain of 6.0%.

Embodiment 3

[0046] Using the same preparation method as in Example 1, the alloy composition is Ti51Al40Nb9 (atomic percentage), the optical floating zone directional solidification process is a relative rotational speed of 25 rpm, the heating power is 70%, the growth rate is 10 mm / h, and the vacuum heat treatment process is 1300 ° C × 20 h +900°C×30min / furnace cooling, the B2 phase is completely eliminated, and the obtained TiAl alloy material has a tensile yield strength of 628MPa at room temperature and a plastic strain of 6.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com