Method for preparing magnesium and magnesium alloy composite grain refiner

A compound crystal and refiner technology, applied in the field of metal materials, can solve the problems of difficult control of process operation, incapable of quantitative analysis, high equipment requirements, etc., achieve good anti-fading ability, improve corrosion resistance and plastic deformation ability, and prepare process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

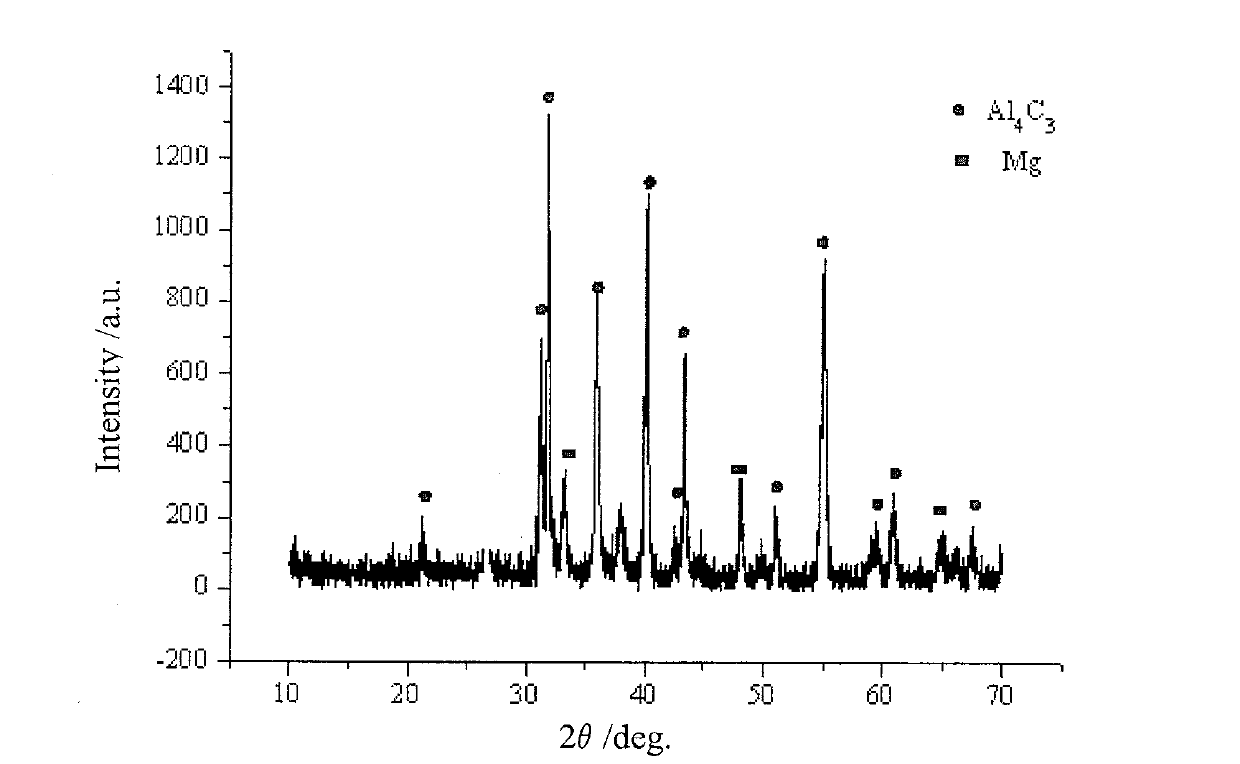

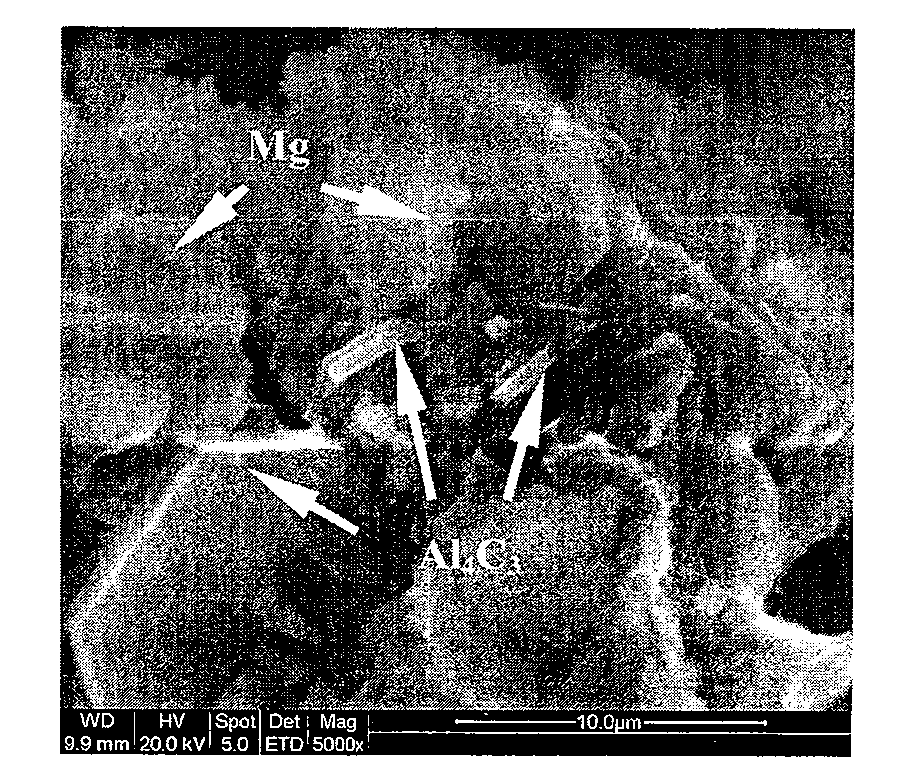

[0041] Example 1: Mg-20%Al 4 C 3 Preparation of -15%Ce Composite Grain Refiner

[0042] (1) 60% by weight of aluminum powder, 20% of carbon powder and 20% of magnesium powder were dry-mixed on a mixer for 12 hours, then cold-pressed into a prefabricated block with a relative density of 45%, wrapped with aluminum foil Dried and buried in a corundum crucible;

[0043] (2) Use a box-type resistance furnace for isothermal treatment at 900°C for 120 minutes;

[0044] (3) Take out the prefabricated block and make Mg-80%Al 4 C 3 master alloy;

[0045] (4) The Mg ingot of 15% by weight, the Mg-80%Al of 25% 4 C 3 Master alloy and 60% Mg-25% Ce master alloy are remelted to produce Mg-20% Al 4 C 3 -15% Ce composite grain refiner.

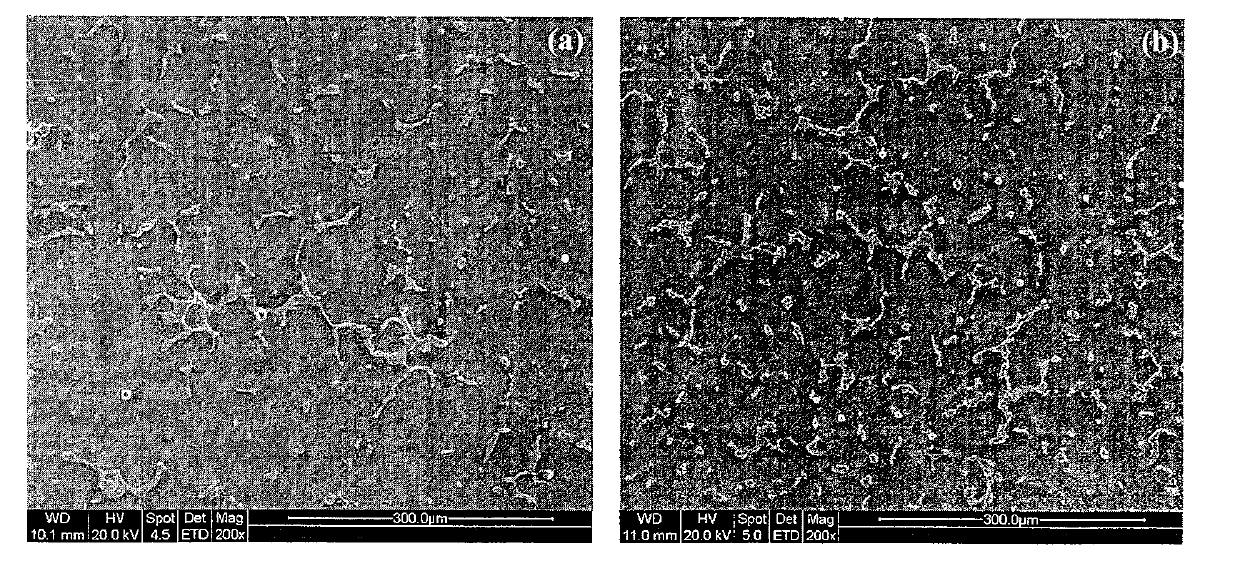

[0046] (5) After adding 1.5% of the composite grain refiner to the AZ91 magnesium alloy, the grain size of the alloy can be reduced from 96 μm to 53 μm.

example 2

[0047] Example 2: Mg-25%Al 4 C 3 Preparation of -12%Ce Composite Grain Refiner

[0048] (1) 37.5% by weight of aluminum powder, 12.5% of carbon powder and 50% of magnesium powder were dry-mixed on a mixer for 6 hours, then cold-pressed into a prefabricated block with a relative density of 50%, wrapped with aluminum foil Dried and buried in a corundum crucible;

[0049] (2) Use a box-type resistance furnace for isothermal treatment, and hold at 700°C for 30 minutes;

[0050] (3) Take out the prefabricated block and make Mg-50%Al 4 C 3 master alloy;

[0051] (4) The Mg ingot of 2% by weight, the Mg-50%Al of 50% 4 C 3 Master alloy and 48% Mg-25% Ce master alloy are remelted to produce Mg-25% Al 4 C 3 -12% Ce composite grain refiner.

[0052] After adding 0.5% of the composite grain refiner to the AZ91 magnesium alloy, the grain size of the alloy can be reduced from 96 μm to 58 μm.

example 3

[0053] Example 3: Mg-40%Al 4 C 3 Preparation of -7%Ce Composite Grain Refiner

[0054] (1) The aluminum powder that is 48% by weight, the carbon powder of 16% and the magnesium powder of 36% are cold-pressed into the prefabricated block of relative density 48% after 8 hours on the mixer, dry after wrapping with aluminum foil processed and buried in corundum crucibles;

[0055] (2) Treat isothermally at 780°C for 60 minutes in a box-type resistance furnace;

[0056] (3) Take out the prefabricated block to make Mg-64%Al 4 C 3 master alloy;

[0057] (4) Mg ingot of 9.5% by weight, Mg-64%Al of 62.5% 4 C 3 Master alloy and 28% Mg-25% Ce master alloy are remelted to produce Mg-40% Al 4 C 3 -7% Ce composite grain refiner.

[0058] After adding 1.0% of the composite grain refiner to the AZ91 magnesium alloy, the grain size of the alloy can be reduced from 96 μm to 56 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com