Preparation method of aluminum based composite material reinforced by aluminium borate whisker coated with CuO

The technology of aluminum matrix composite material and aluminum borate whisker is applied in the field of preparation of whisker reinforced aluminum matrix composite material, which can solve the problems of poor mechanical properties and cannot be used in high temperature environment, and achieves the improvement of elongation and the improvement of high temperature interface. Stability, uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

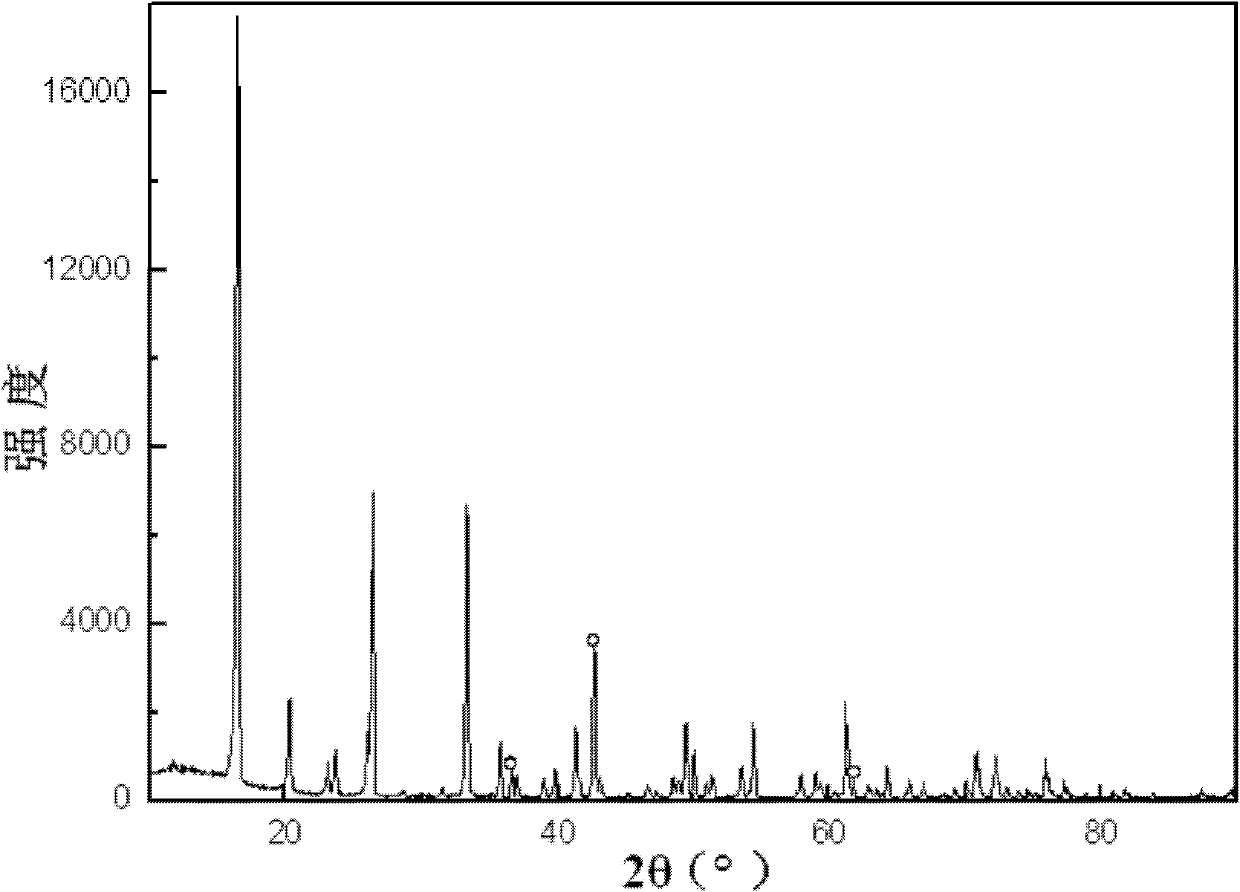

[0021] Specific implementation mode 1: In this implementation mode, CuO-coated aluminum borate whisker-reinforced aluminum matrix composite material is carried out according to the following steps:

[0022] 1. Add copper nitrate and citric acid into distilled water at a molar ratio of 1:1, then magnetically stir and heat to reflux for 1-2 hours to obtain a transparent CuO sol;

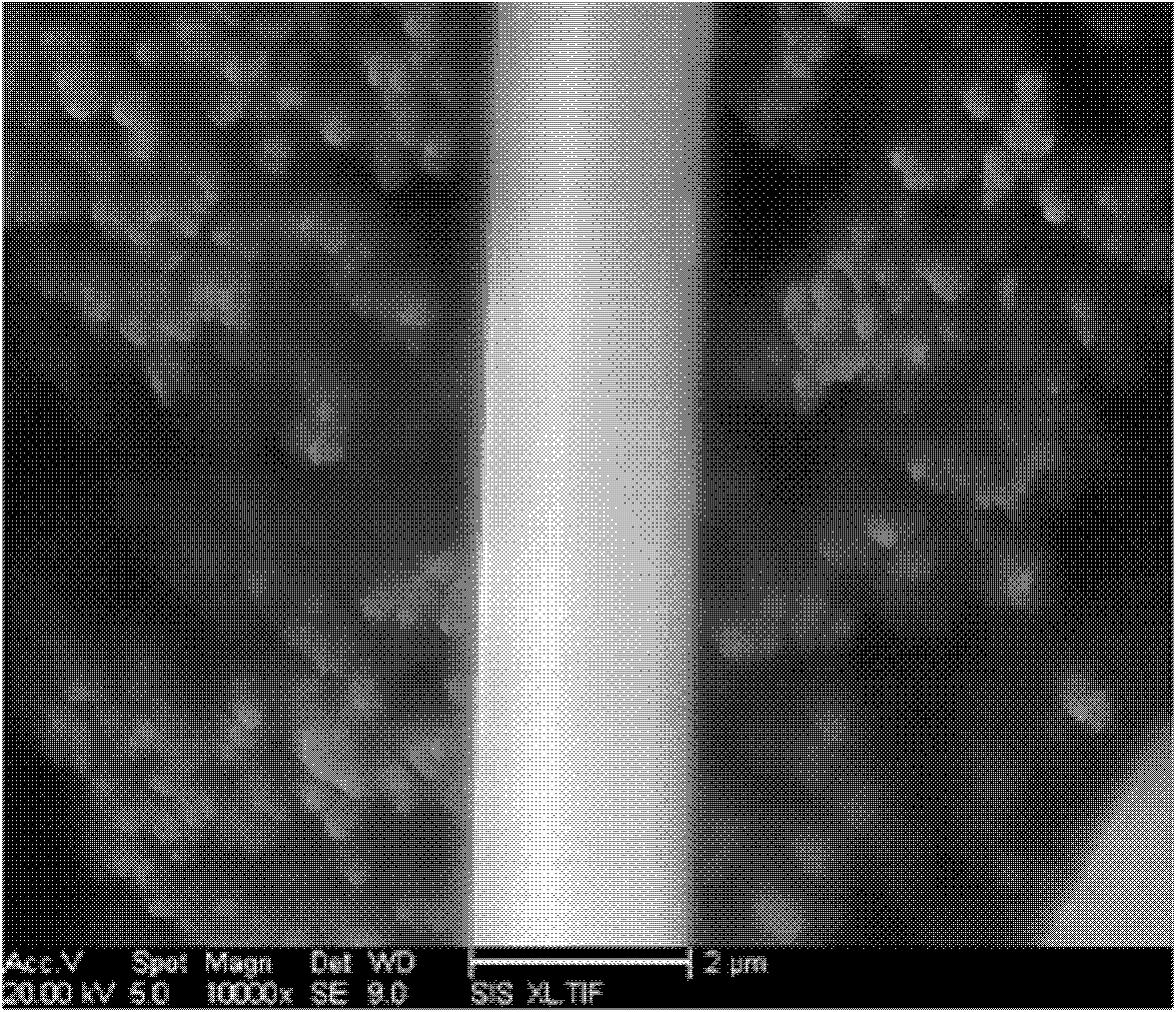

[0023] 2. Add aluminum borate whiskers to CuO sol and disperse them with ultrasonic waves, and then dry them to obtain CuO gel-coated aluminum borate whiskers;

[0024] 3. Put the CuO gel-coated aluminum borate whiskers in an environment of 400-600°C and roast for 1-3 hours to make CuO-coated aluminum borate whiskers, and then put them into water for ultrasonic dispersion for 1-2 hours;

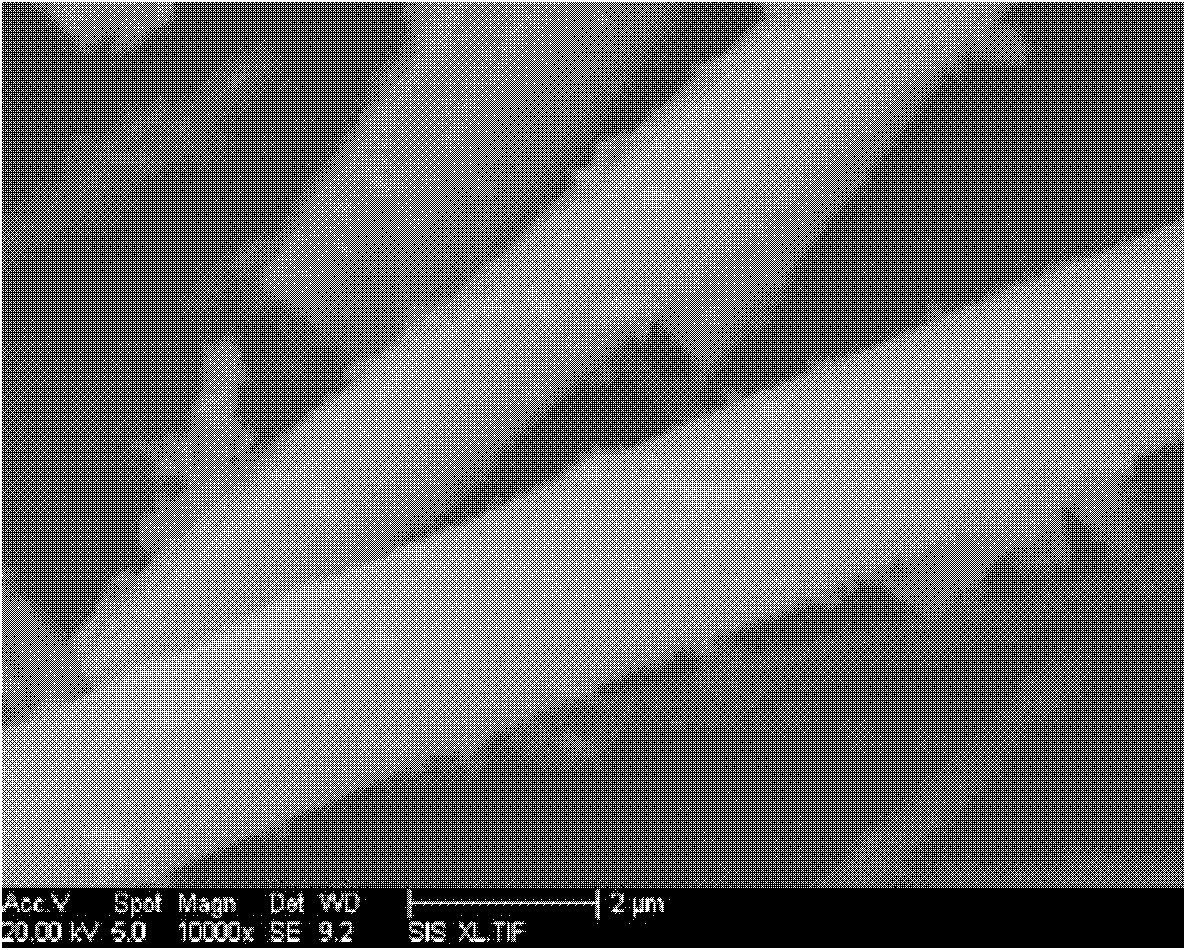

[0025] 4. Make prefabricated parts of CuO-coated aluminum borate whiskers that have been ultrasonically dispersed in Step 3 by compression molding, then dry at room temperature, and then bake in an environment of 800-...

specific Embodiment approach 2

[0029] Embodiment 2: The differences between this embodiment and Embodiment 1 are: in step 2, the ultrasonic dispersion time is 1-3 hours, the ultrasonic power is 1000-2000 W, and the ultrasonic frequency is 50-80 Hz. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 5, the CuO-coated aluminum borate whisker preform accounts for 17%-28% of the total volume of the aluminum matrix composite material. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com