High-strength wear-resistant high-transmission polycarbonate film

A polycarbonate, high-strength technology, applied in the field of polycarbonate resin, can solve the problems of poor scratch resistance, no large-scale production, limited application scope, etc., to improve strength and tensile ductility, wear resistance and Improved finish, versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

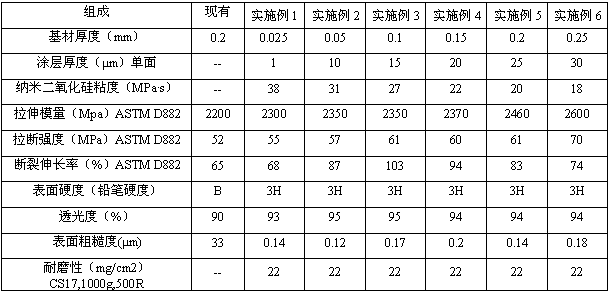

[0013] A high-strength wear-resistant and high-transparency polycarbonate film, comprising a substrate made of polycarbonate, the substrate is a sheet or film with a thickness of 0.025 mm to 0.25 mm, and the upper and lower sides of the sheet or film are At least one surface is sprayed with a layer of nano silicon dioxide cured by ultraviolet drying, and the average spray thickness of one side is 1 ~ 100 μm. As preferably in the present invention, the single side average spray coating of the nano silicon dioxide coating The thickness is 10 μm ~ 30 μm; the viscosity of nano silica used as coating in the present invention is 18 ~ 38 MPa s, the particle size distribution is more than 99% of the split particles of 0.1 μm ~ 0.5 μm, and the specific surface area is 25 ~ 100m 2 / g.

[0014] The raw material of the substrate used in the present invention is selected from the copolymerization of bisphenol A polycarbonate, polyester polycarbonate, organosilicon polycarbonate, cyclohexan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com