Heat insulation glass

A heat-insulating glass and glass layer technology, applied in the direction of glass/slag layered products, layered products, chemical instruments and methods, etc., can solve problems such as poor heat insulation effect, so as not to affect light transmission performance and structure Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

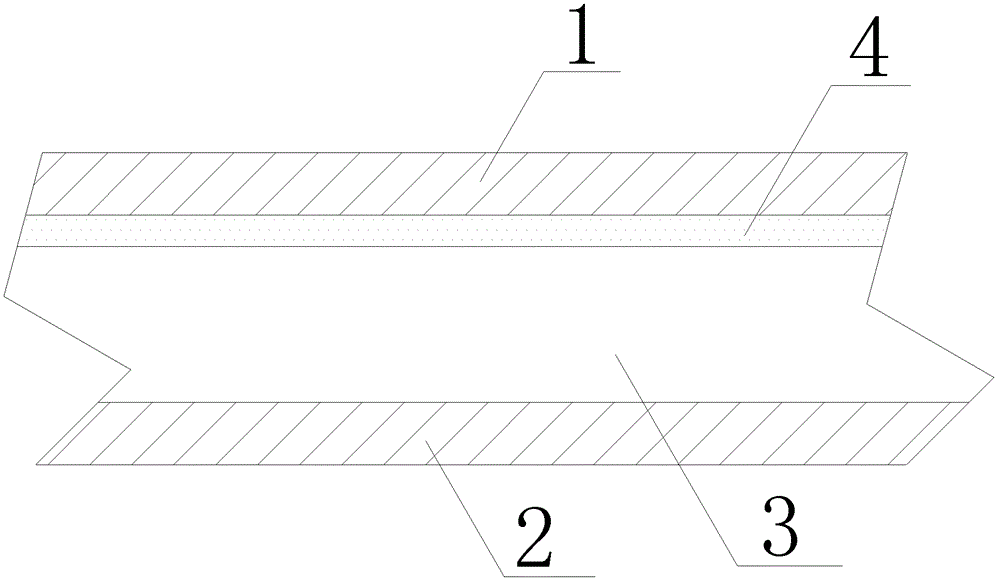

[0012] As shown in the figure, the present invention is a kind of heat insulating glass, which includes a first glass layer 1 and a second glass layer 2, and the interlayer between the first glass layer 1 and the second glass layer 2 has a light-transmitting heat insulating board 3, One side of the light-transmitting heat insulation board 3 is coated with a metal particle layer 4, the composition of the metal particle layer 4 is titanium dioxide or cobalt dioxide, the metal particles in the metal particle layer 4 are nanoscale in size, and the layer thickness is also nanometer or Approximate nanometer size.

[0013] Due to the use of the light-transmitting heat insulation board and the nano-metal layer at the same time, the light-transmitting heat-shielding board itself can insulate heat, and the nano-metal layer reflects solar radiation, so the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com