Device and test method for testing circumferential fracture toughness of thin-wall pipe

A thin-walled pipe, fracture toughness technology, used in measuring devices, using stable tension/pressure to test the strength of materials, analyzing materials, etc. , to achieve the effect of avoiding sample defects and direct testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The device and test method for testing the circumferential fracture toughness of thin-walled pipes according to the present invention will be described in detail below in conjunction with the accompanying drawings and examples:

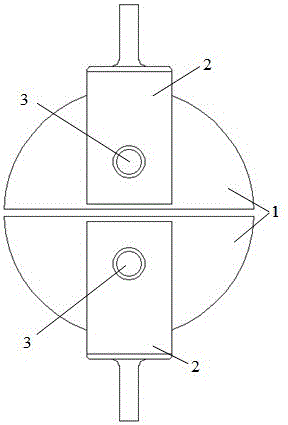

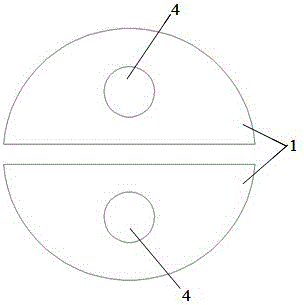

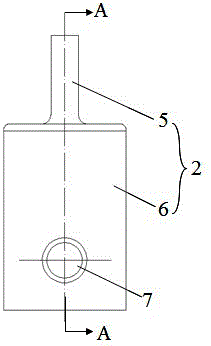

[0041] Such as Figure 1~4 As shown, a device for testing the hoop tensile strength of thin-walled pipes includes a disc-shaped holder 1, two connectors 2 and a fixing pin 3 for fixing the holder 1 and the connector 2; the holder 1 Divided into two semi-circles of equal size, each semi-circle is formed with a fixing hole 4; the connecting tool 2 is composed of a connecting handle 5 and a "ㄇ" type connecting head 6; the connecting handle 5 and the connecting head 6 beam The center is fixed; pin holes 7 are formed on both side walls of the connector 6 .

[0042] The axis of the pin hole 7 is perpendicular to the axis of the connecting handle 5 .

[0043] The holding tool 1 is placed in the gap between two "ㄇ" type connectors 6.

[0044] The ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com