Prediction method for mixed type delamination resistance curve of composite

A layered resistance, composite material technology, applied in the direction of analyzing materials, using stable bending force to test material strength, using stable tension/pressure to test material strength, etc. and other problems, to achieve the effect of reducing workload, reducing test cost, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is described in further detail below in conjunction with embodiment.

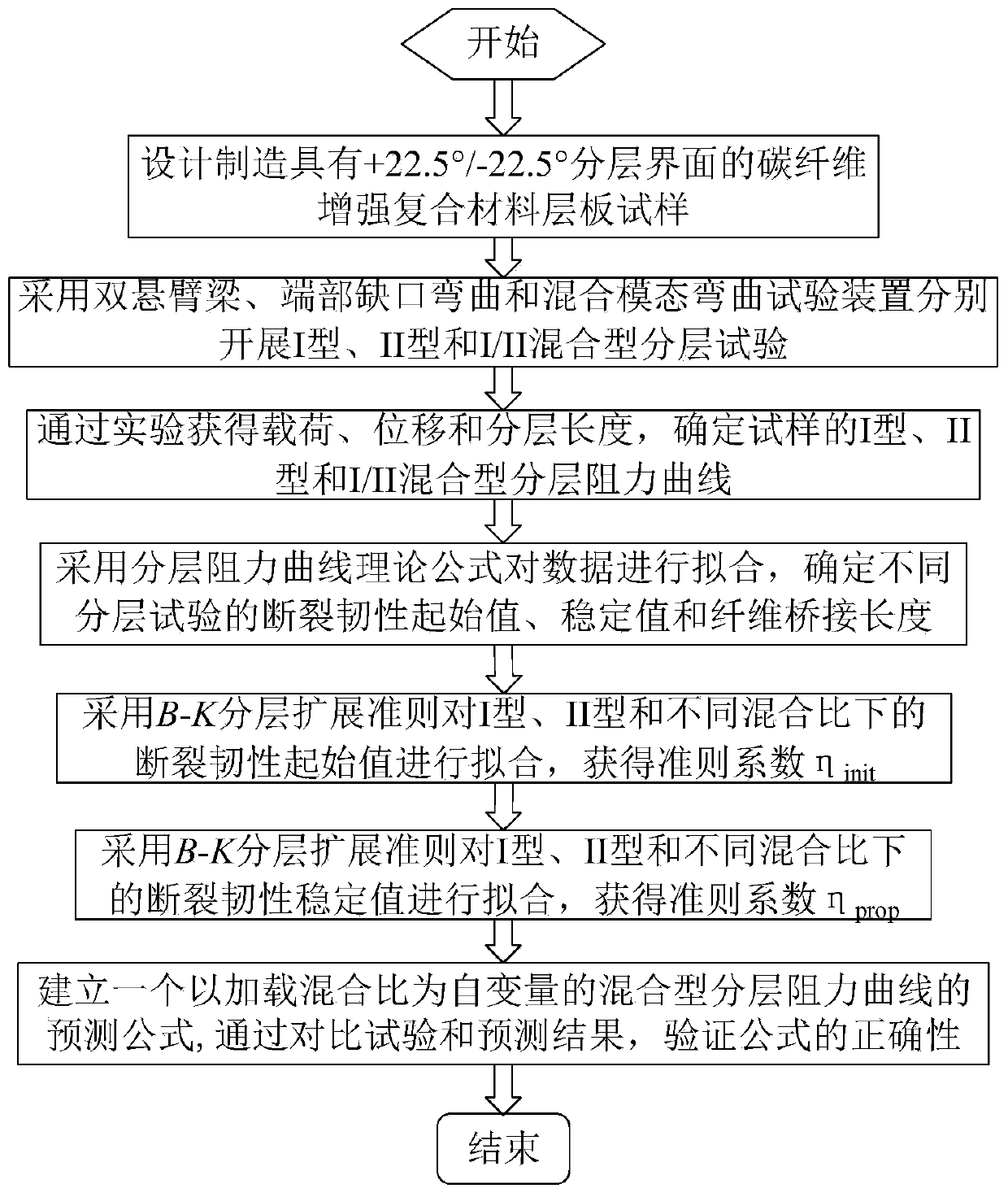

[0047] A method for predicting the hybrid layered resistance curve of a composite material according to the present invention, the specific implementation steps are as follows:

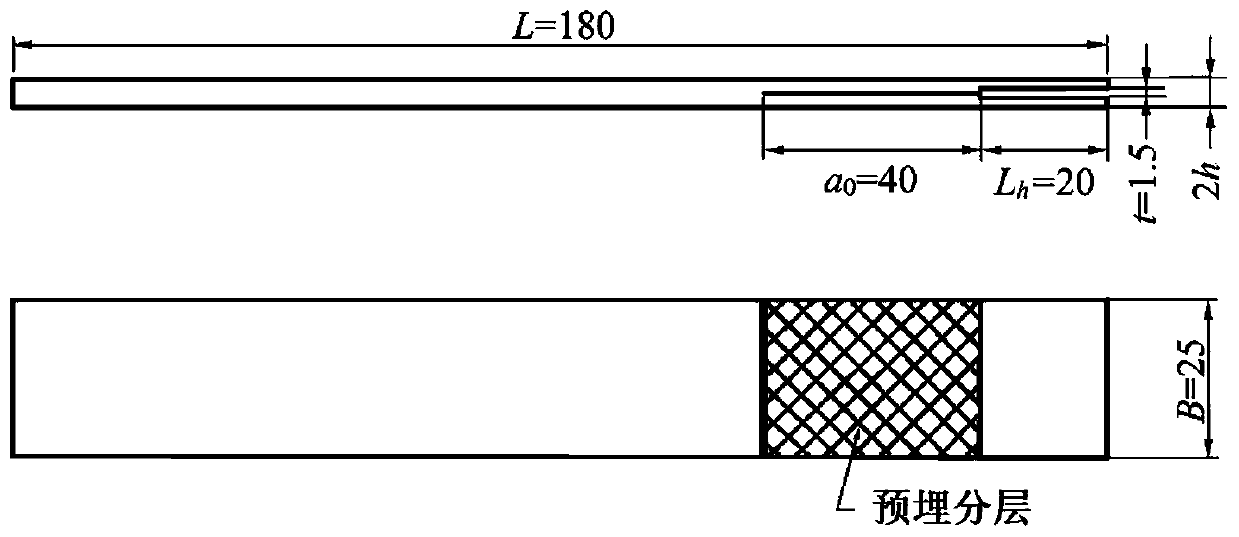

[0048] Step 1: Design and fabricate specimens with +22.5° / -22.5° delamination interface according to ASTM standard D5528-13. The order of sample layup is (+22.5° / -22.5°) 6 / / (+22.5° / -22.5°) 6 . DCB, ENF and MMB experiments use the same configuration and geometric size of the sample. Specimen configuration and geometry such as figure 2 shown. Carbon fiber-reinforced composite laminates are obtained by using T800 carbon fiber / epoxy resin unidirectional tape prepregs, which are stacked according to the specified lay-up sequence and then cured.

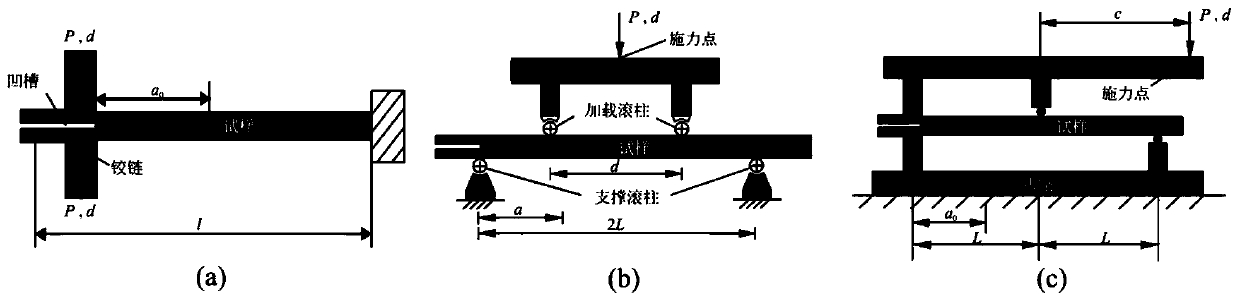

[0049] Step 2: Refer to ASTM standards D5528-13, D7905 / D7905M-14 and D6671 / D6671M-13e1 respectively to carry out Type I, Type II and Mixed Type I / II static d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com