Method for testing fracture toughness of rattan canes based on three-point bending mode

A technology of three-point bending and fracture toughness, which is applied in the field of measurement, can solve problems such as complex structure, inability to fully conduct performance tests, and influence on material development, and achieve good reproducibility, high accuracy, and improved test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Experimental material and sample size

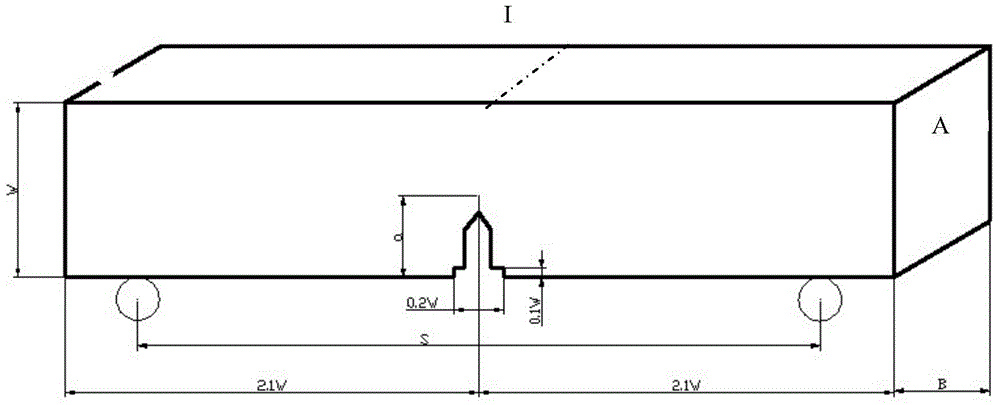

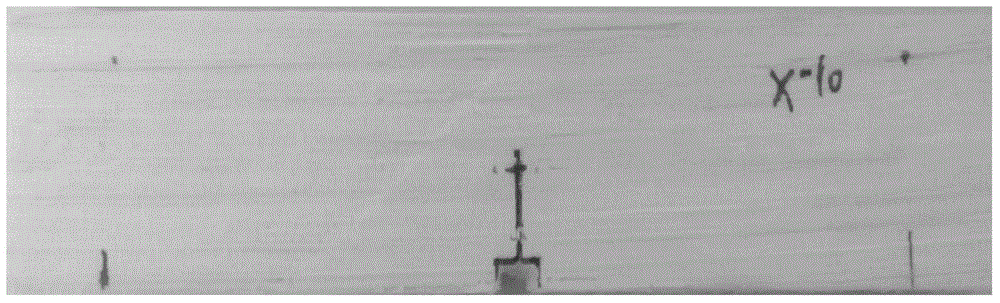

[0039] Hook leaf rattan, 30-40mm in diameter, collected in Yingjiang County, Dehong Prefecture, Yunnan Province. The size of SEB specimens is based on "ASTM E399 Linear-Elastic Plane Strain Fracture Toughness of Metal Materials K Ic The requirements in the test method are prepared (such as figure 1 As shown, S=4W, B=W / 2, a / W=-0.45~0.55). The thickness of the test piece is 10mm, the width is 20mm, the crack depth is 10mm, and the number of test pieces is not less than 20. The processed test piece is placed in a constant temperature and humidity box under the conditions of temperature 20°C and humidity 65% to adjust the balance, and the moisture content of the sample is 10-12%.

[0040] 2. Crack prefabrication

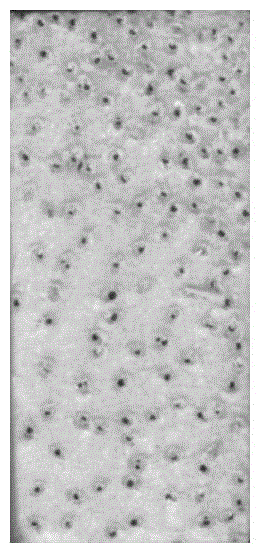

[0041] The distribution of vascular bundles in the diameter direction of the cane is uneven, the distribution of vascular bundles is dense at the cane bark, and the distribution of vascular bundles is sparse at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Crack depth | aaaaa | aaaaa |

| Crack depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com