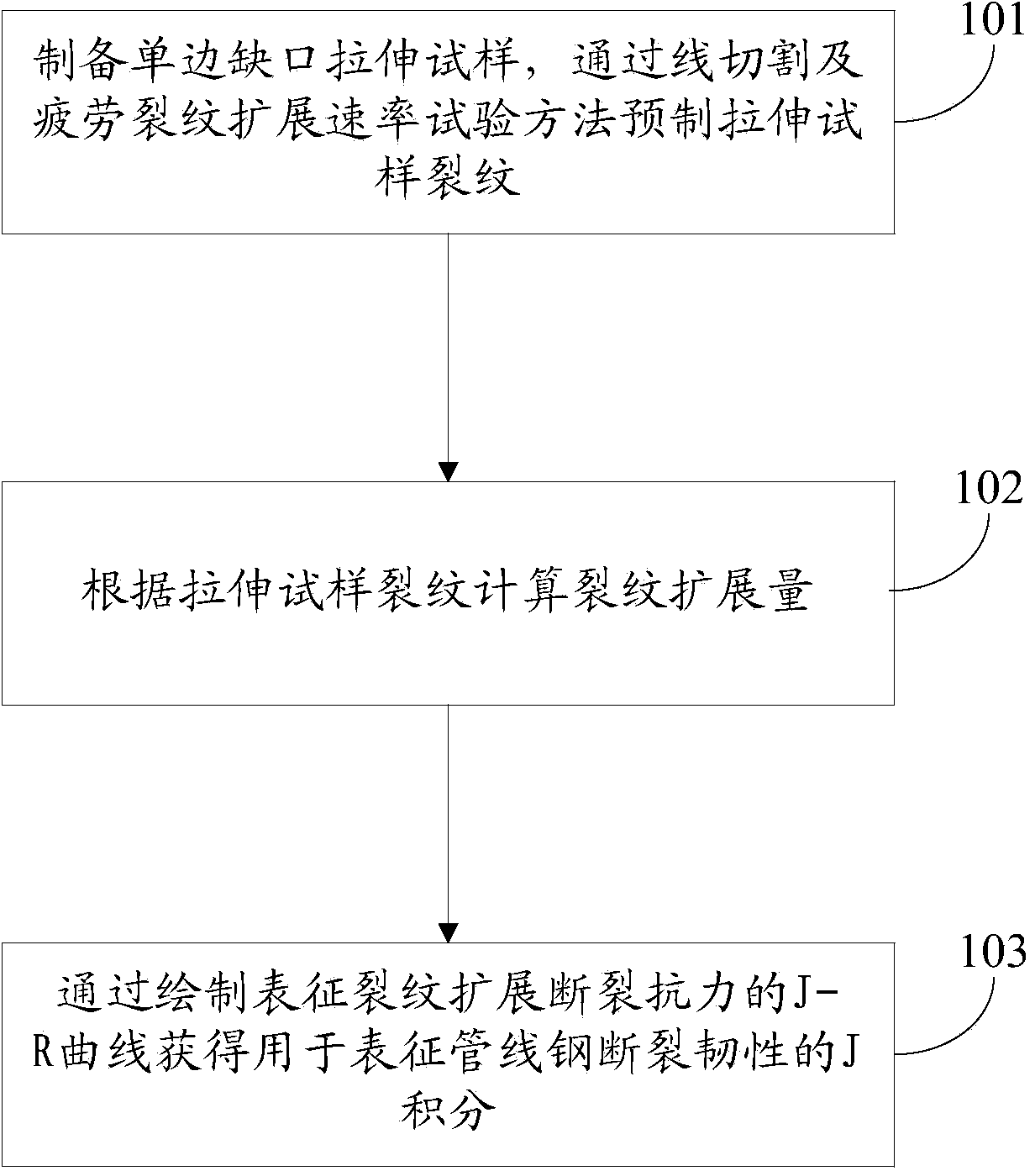

Method for measuring fracture toughness of pipeline steel by using unilateral notched tensile test

A fracture toughness and tensile test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of small range of measurement results and insufficient assessment of fracture toughness of pipeline steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

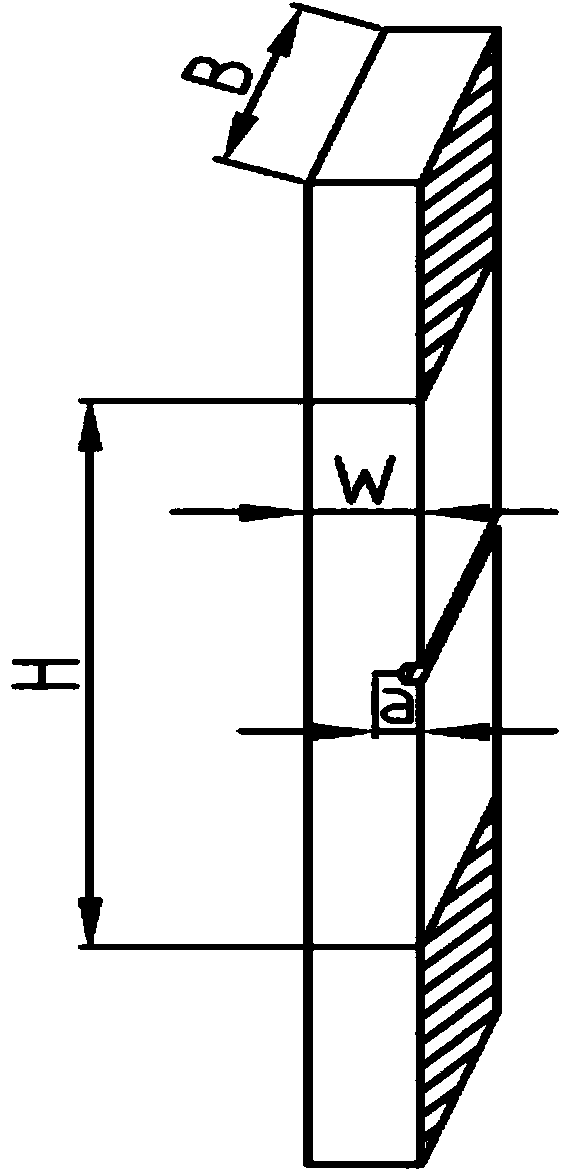

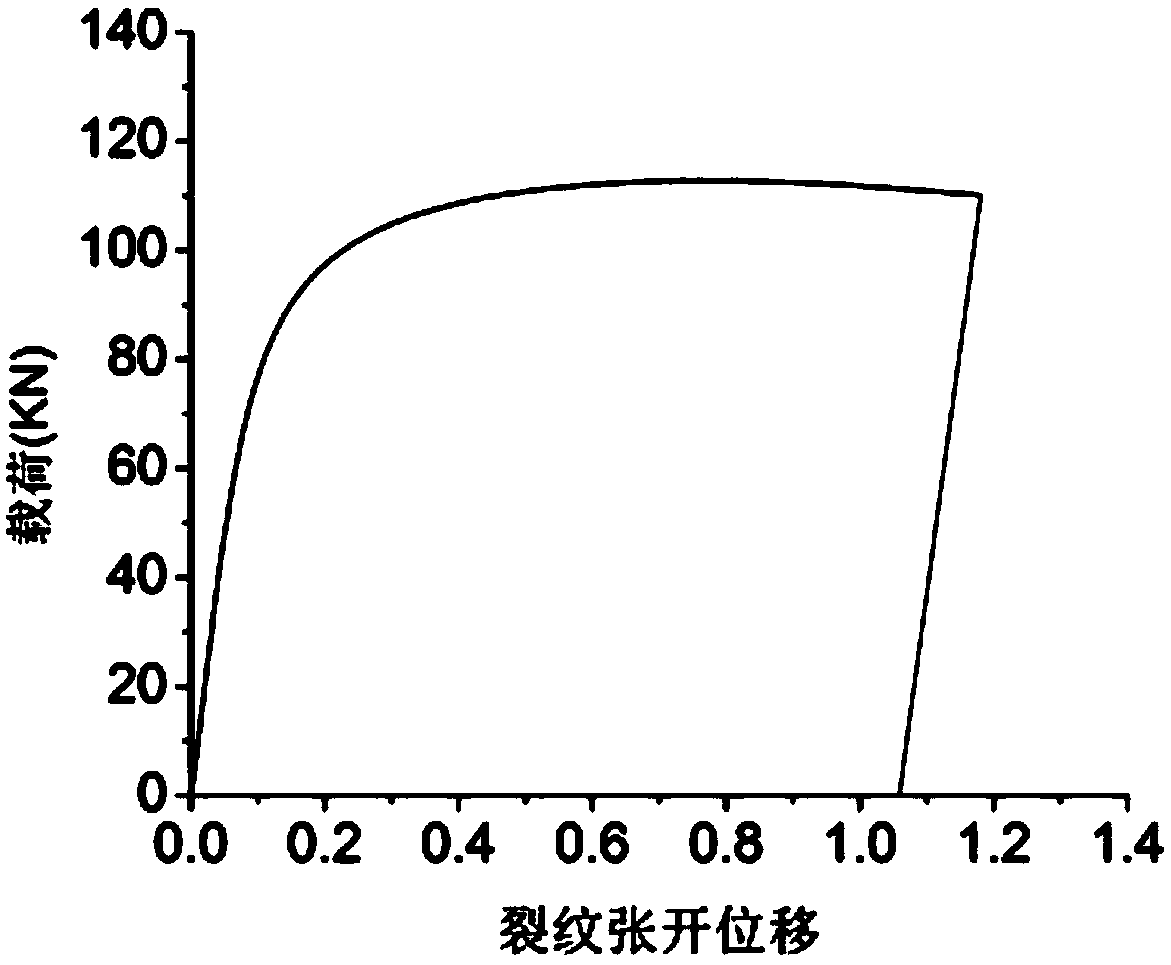

[0054] Example 1: Prepare a tensile sample (SENT sample) for a pipeline steel with a yield ratio of 0.85 and a thickness B of 5mm. The sample size refers to the attached figure 2 , the width of the sample is W=0.75t, the processing of the sample crack can be divided into wire cutting and fatigue prefabrication, and the fatigue crack of 2mm size is prefabricated according to the ASTM1820 standard. The prefabricated fatigue cracked sample is loaded on the MTS tensile machine. The sample is clamped vertically. The entire loading process is carried out at room temperature to reduce the influence of temperature. The loading method is displacement control, and the rate is 2mm. / min, each group of samples must be stretched at least six times in different degrees, and at least three samples should be loaded beyond the highest load point to ensure that the crack growth is 0.5mm. After the loading process of the tensile specimen is finished, the crack growth amount Δa is measured by th...

example 2

[0055] Example 2: Prepare a tensile sample (SENT sample) for a pipeline steel with a yield ratio of 0.85 and a thickness B of 6mm. The sample size refers to the attached figure 2 , the width of the sample is W=0.75t, the processing of the sample crack can be divided into wire cutting and fatigue prefabrication, and the fatigue crack of 2mm size is prefabricated according to the ASTM1820 standard. The prefabricated fatigue cracked sample is loaded on the MTS tensile machine. The sample is clamped vertically. The entire loading process is carried out at room temperature to reduce the influence of temperature. The loading method is displacement control, and the rate is 1mm. / min, each group of samples must be stretched at least six times in different degrees, and at least three samples should be loaded beyond the highest load point to ensure that the crack growth is between 1mm. After the loading process of the tensile specimen is finished, the amount of crack growth is measured...

example 3

[0056] Example 3: Prepare a tensile sample (SENT sample) for a pipeline steel with a yield ratio of 0.90 and a thickness B of 5mm. The sample size refers to the attached figure 2 , the width of the sample is W=0.70t, the processing of the sample crack can be divided into wire cutting and fatigue prefabrication, and the fatigue crack of 2mm size is prefabricated according to the ASTM1820 standard. The prefabricated fatigue cracked sample is loaded on the MTS tensile machine. The sample is clamped vertically. The entire loading process is carried out at room temperature to reduce the influence of temperature. The loading method is displacement control, and the rate is 2mm. / min, each group of samples must be stretched at least six times to different degrees, and at least three samples should be loaded beyond the highest load point to ensure that the crack growth is between 0.2mm. At the end of the loading process of the tensile sample, the amount of crack growth is measured by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com